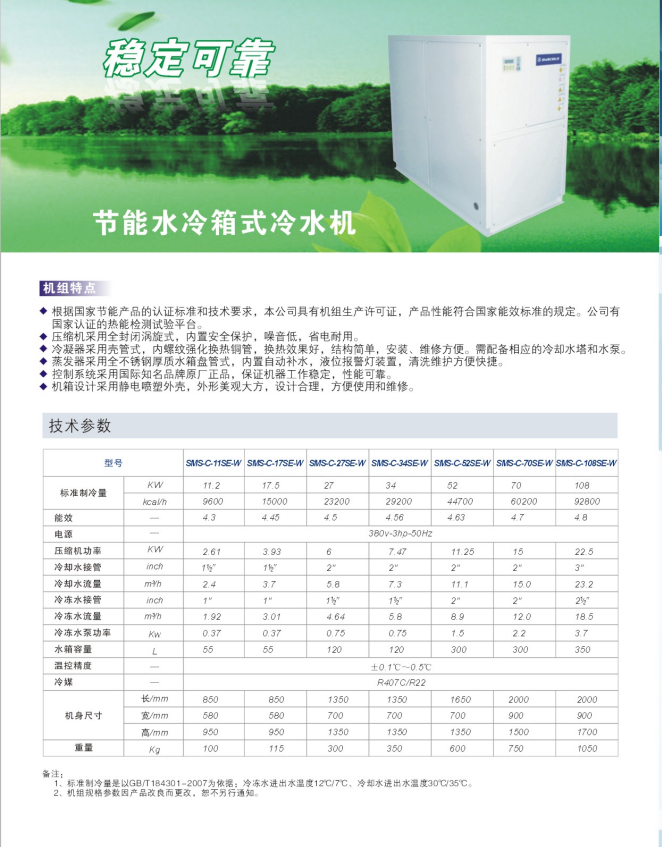

Features of Xinglu Water-Cooled Chillers:

1. All piping is insulated to prevent localized convection within the machine's piping system. 2. Cooling temperature range: 5°C - 35°C. 3. Independent temperature controller with freeze protection. 4. Stainless steel insulated water tank. 5. Control circuit phase sequence protection, high and low-pressure switches for the refrigerant system. 6. Hydrophilic aluminum fin condenser with better heat transfer efficiency and faster heat dissipation. 7. Overload protection for compressors and pumps. 8. Large-capacity shell-and-tube evaporator for excellent cooling performance, suitable for higher ambient temperatures. 9. Refrigerant R22, providing good cooling effect. 10. Optional environmentally friendly refrigerant R407C, more eco-friendly. Usage: Chillers are generally used in air conditioning units and industrial cooling. In air conditioning systems, chilled water is typically distributed to heat exchangers or coils in air handling units or other types of terminal equipment to cool their respective spaces, then the chilled water is redistributed back to the chiller after being cooled. In industrial applications, chilled water or other cooling liquids are pumped through processes or laboratory equipment. Industrial chillers are used across various industries to control the cooling of products, mechanisms, and factory machinery. Chillers can generally be classified into water-cooled and air-cooled types based on cooling methods. Technically, water-cooled chillers have an energy efficiency ratio 300 to 500 kcal/h higher than air-cooled ones; price-wise, water-cooled chillers are much cheaper; installation-wise, water-cooled chillers require a cooling tower, while air-cooled chillers are portable and do not need additional auxiliary equipment. However, air-cooled chillers rely solely on fans for heat dissipation and have environmental requirements such as ventilation, humidity, and temperature not exceeding 40°C, as well as air pH levels...

Whats App

Whats App

Plastmatch App

Scan the QR code

Plastmatch App

Scan the QR code 1000+ Daily Updated Global Business Leads,2M+ Global Company Database.Click to download the app.

Purchase request Download app