Xinglu water-cooled screw chillers are widely used in industries such as chemical processing, extrusion, aluminum alloy processing, food processing, pharmaceuticals, electronics, and new energy, all of which require cooling. Xinglu Refrigeration has been dedicated to refrigeration for many years and boasts several industry-leading technical experts. We continuously improve and optimize our products. Our company provides comprehensive technical support to customers throughout the process, from model selection to installation and commissioning.

Features:

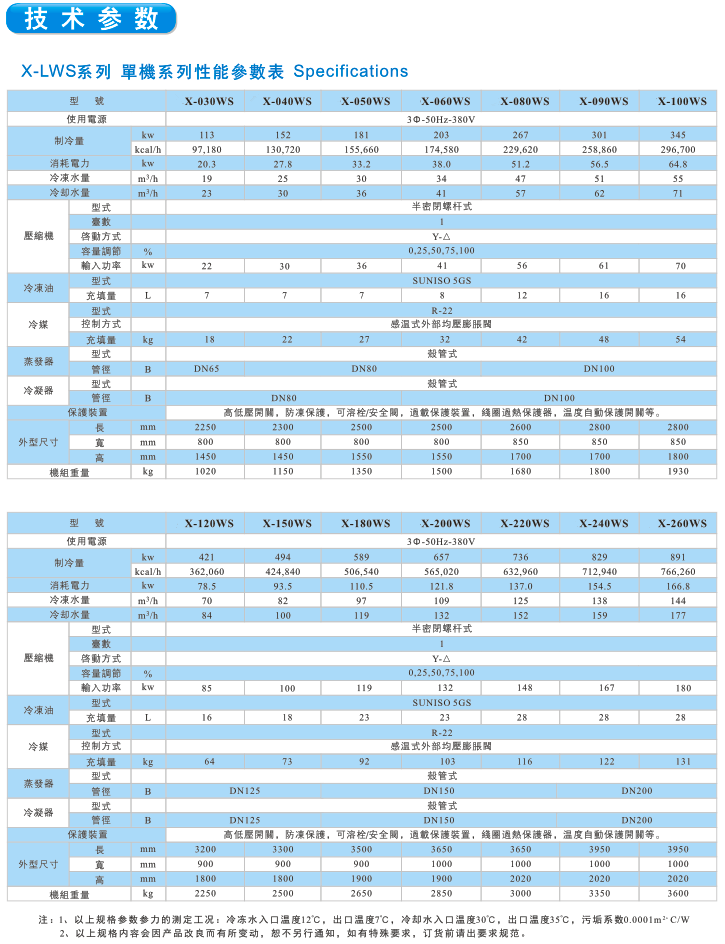

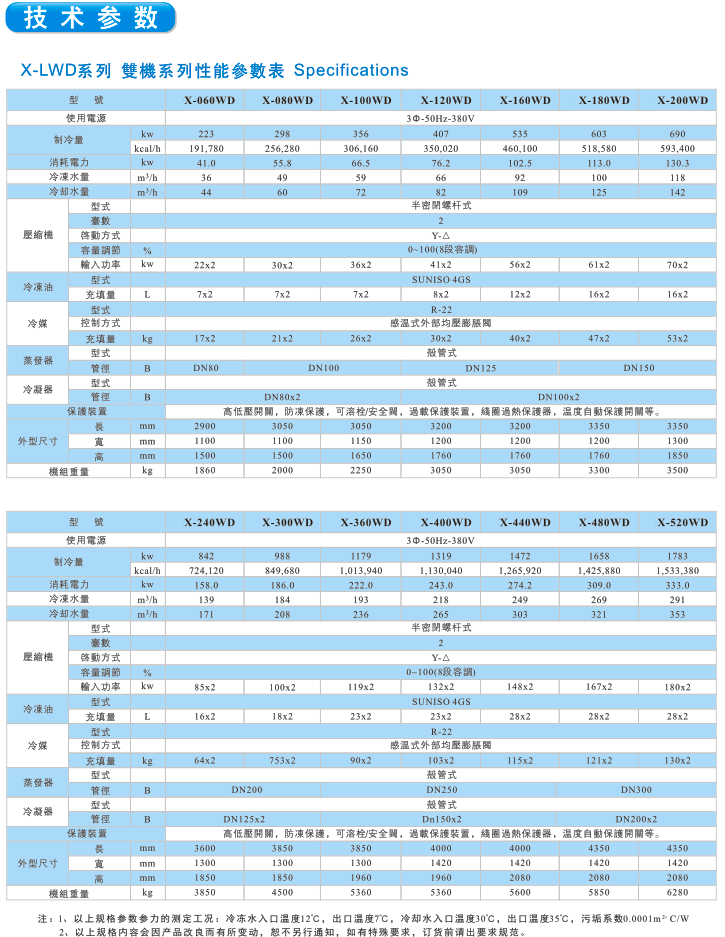

1. Equipped with original imported high-efficiency energy-saving compressors from international brands such as BITZER (Germany) and HANBELL (Taiwan), matched with high-quality condensers and evaporators. These components ensure high efficiency, stable performance, low noise, and long service life. An industrial-grade PLC controls the chiller centrally, ensuring precise control of the refrigeration capacity to match the cooling load, thereby optimizing operational efficiency and reducing operating costs.

2. Integrated safety protection features include water cut-off, low-temperature, high/low pressure freeze prevention, phase loss delay start, reverse phase overload, motor overheat, oil pressure differential, and other protective functions.

3. User-friendly Chinese operation interface with menu prompts allows for easy setting of the chiller's operating status, providing an appliance-like user experience.

4. Capacity control can be achieved through four-stage (100%-75%-50%-25%) or three-stage (100%-66%-33%) stepless control systems.

5. Unique built-in oil pressure system ensures optimal lubrication of the compressor without the need for an oil pump. The oil separator uses a dual-layer filtration method for excellent oil filtering effects, and the heat exchanger operates at maximum efficiency.

6. High-efficiency internally grooved copper tubes enhance heat transfer, making the system more energy-efficient. Utilizing the latest CAD/CAM design and manufacturing technology, CNC machining centers ensure compact structure, small size, durability, and longevity. The U-shaped heat exchange tube bundle is easy to maintain and prevents refrigerant leakage.

Whats App

Whats App

Plastmatch App

Scan the QR code

Plastmatch App

Scan the QR code 1000+ Daily Updated Global Business Leads,2M+ Global Company Database.Click to download the app.

Purchase request Download app