1.SZ TypeWater Ring Vacuum Pump Usage and Specifications:

SZWater Ring Vacuum Pump and compressor are used to suck or compress air and other non-corrosive gases that are insoluble in water, to create vacuum and pressure in a closed container.

SZWater Ring Vacuum Pump has four specifications: SZ-1, SZ-2, SZ-3, and SZ-4, with the maximum vacuum degree ranging from 86% to 95%. The maximum pressure that SZ-1 and SZ-2 can achieve is 1.0-1.4 kg/cm², while SZ-3 and SZ-4 can achieve a maximum pressure of 1.5 kg/cm², depending on the power of the motor; if the motor power is increased, the maximum pressure can reach 2.1 kg/cm² (pump type meaning: for example, SZ-1, S - Water Ring, Z - Vacuum Pump, 1 - Serial Number of the Pump)

2.SZ TypeWater Ring Vacuum Pump Working Principle:

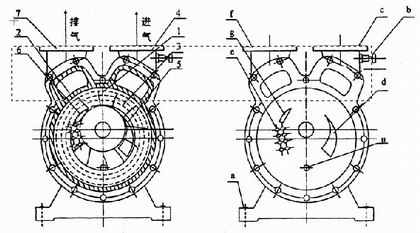

SZWater Ring Vacuum Pump is shown in Figure 1. The impeller ① is eccentrically installed in the pump body ②. When starting, a certain height of water is injected into the pump.

Therefore, when the impeller rotates, the water, under the action of centrifugal force, forms a rotating water ring ③ on the pump body wall. The upper inner surface of the water ring is tangent to the hub and rotates in the main direction indicated by the arrow. During the first half of the rotation, the inner surface of the water ring gradually separates from the hub, which creates and gradually enlarges a space between the impeller blades, allowing air to be sucked in through the intake port; during the second half of the rotation, the inner surface of the water ring gradually approaches the hub, and the volume of space between the blades decreases, thus compressing the air between the blades and expelling it.

Therefore, each time the impeller completes a rotation, the volume of space between the blades changes, and each blade acts like a piston, allowing the SZ Water Ring Vacuum Pump to continuously suck gas.

As the water heats up during operation and some of the water is expelled along with the gas, the SZ Water Ring Vacuum Pump must continuously supply cold water during operation to cool and replenish the water consumed in the pump. The supplied cold water should ideally be at 15°C.

When the gas discharged from the SZWater Ring Vacuum Pump is waste gas, a water tank is connected at the discharge end. After the waste gas and part of the water are expelled into the water tank, the gas escapes through the outlet pipe of the water tank while the water falls to the bottom of the tank and returns to the pump through the return water pipe. If the circulation time is prolonged, the water will heat up; in this case, a certain amount of cold water must be supplied from the water supply of the tank.

|

|

Figure 1

|

Figure 2

|

| 1. Impeller 2. Pump Body 3. Water Ring 4. Intake Pipe 5. Air Inlet 6. Air Outlet 7. Exhaust Pipe | a. Base b. Vacuum Adjustment Valve c. Intake Pipe d. Air Inlet e. Rubber Valve f. Exhaust Pipe g. Air Outlet u. Water Inlet |

|

Structure Diagram of Water Ring Vacuum Pump and Compressor

|

|

As the water heats up during operation and some of the water is expelled along with the gas, the SZWater Ring Vacuum Pump must continuously supply cold water during operation to cool and replenish the water consumed in the pump.

When the SZWater Ring Vacuum Pump discharges waste gas, a water tank is connected at the discharge end. After the waste water and part of the water are expelled into the water tank, the gas escapes through the outlet pipe of the water tank while the water falls to the bottom of the tank and returns to the pump through the return water pipe. If the water circulation time is prolonged, it will heat up; in this case, a certain amount of cold water must be supplied from the water supply of the tank.

When SZWater Ring Vacuum Pump is used as a compressor, a gas-water separator must be connected at the discharge end. When gas containing water enters the separator, it automatically separates, with the gas being sent to the desired location from the outlet of the separator, while hot water is released through an automatic switch. (During compression of gas...)