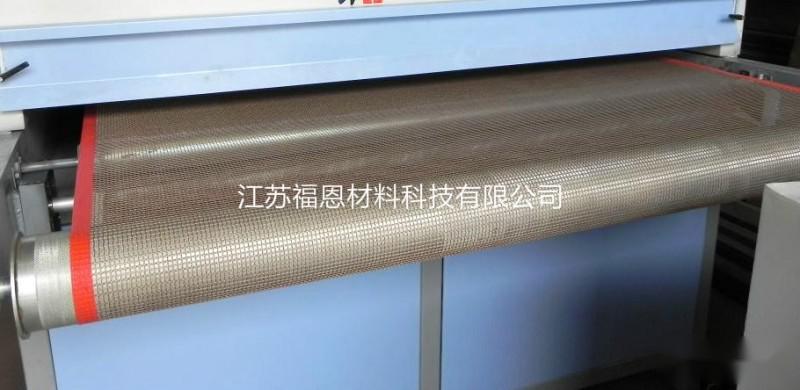

The Teflon mesh belt is defined by the size of the mesh holes, mainly including 1×1MM, 2×2.5MM, 4×4MM, 10×10MM, etc., and is categorized into single warp and double warp Teflon mesh fabric based on the differences in warp and weft.

Features

· High and low temperature resistance -70℃ to 260℃. Weather resistant, anti-aging, and long service life.

· Anti-stick and easy to clean.

· Resistant to various strong acids and alkalis, chemical resistant, and non-toxic.

· Size stability, elongation coefficient less than 5‰, high strength, and good mechanical properties.

· Bending fatigue resistance, suitable for smaller wheel diameters.

· Fireproof and flame retardant, breathable, reducing heat loss, and improving drying efficiency.

Applications

The Teflon mesh belt has the characteristic of easy air permeability due to its mesh holes, making it widely used in textile printing, printing drying guide belts, screen printing, UV drying, UV series, photopolymerization machines, offset printing machines, loose dryers, non-woven drying machines, high-frequency dryers, food baking machine guide belts, temperature control baking rooms, solvent type rapid drying and drying of generally moisture-containing items, etc.

The Teflon mesh belt has high temperature resistance, low surface friction coefficient and excellent insulation properties, widely used in bonding machines, garment printing, and other machinery.

Common specifications table

|

Grade |

Aperture |

Material |

Thickness |

Weight |

Temperature Resistance |

Max Width |

Tensile Strength |

|

W-O5J |

1x 1mm |

Fiberglass |

0.5mm |

370g /m² |

-70 -260 ℃ |

4m |

310/290 N/cm |

|

W-07J |

2x 2mm |

Fiberglass |

0.7mm |

450g /m² |

-70 -260 ℃ |

4m |

350/310 N/cm |

|

W-1J |

4x 4mm |

Fiberglass |

1.0mm |

400g /m² |

-70 -260 ℃ |

4m |

390/320 N/cm |

|

W-2J |

4x 4mm |

Fiberglass |

1.0mm |

450g /m² |

-70 -260 ℃ |

4m |

390/320 N/cm |

|

W-12KJ |

4x 4mm |

Kevlar Fiberglass |

1.2mm |

600g /m² |

-70 -260 ℃ |

4m |

895/370 N/cm |

|

W-3J |

4x 4mm |

Fiberglass |

1.0mm |

500g /m² |

-70 -260 ℃ |

4m |

395/370 N/cm |

|

W-4J |

4x 4mm |

Fiberglass |

1.0mm |

500g /m² |

-70 -260 ℃ |

4m |

900/600 N/cm |

|

W-5J |

4x 4mm |

Fiberglass |

1.0mm |

550g /m² |

-70 -260 ℃ |

4m |

395/370 N/cm |

|

W-12J |

10x 10mm |

Fiberglass |

1.2mm |

450g /m² |

-70 -260 ℃ |

4m |

360/300 N/cm |

|

NW-14J |

0.5x 1mm |

Fiberglass |

0.5mm |

420g /m² |

-70 -260 ℃ |

4m |

310/290 N/cm |

|

W-09J |

2x 2.5mm |

Fiberglass |

0.9mm |

600g /m² |

-70 -260 ℃ |

3m |

390/320 N/cm |

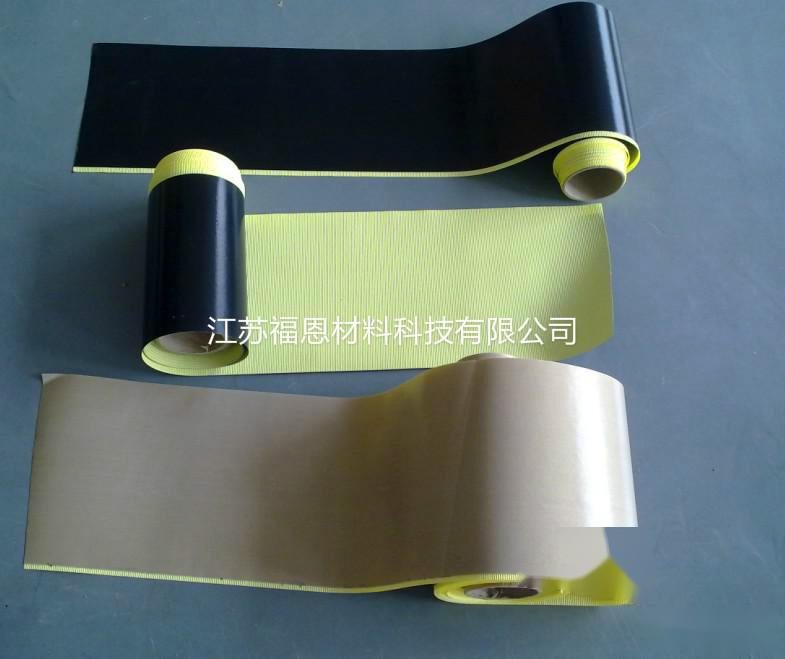

Joint Styles

The Teflon mesh belt joint methods mainly include cow nose joints (soft joints) and steel buckle joints.

There are various joint methods for Teflon mesh belts, such as butt joints, overlap joints, tapered overlapping joints, and steel buckle joints.

Styles of edge wrapping for Teflon mesh belts:

Teflon turned film edge wrapping, Kevlar fabric edge wrapping, Teflon fabric edge wrapping, etc.

Supplement on the mesh belt: Due to the different widths of the equipment, it is recommended to use double warp for ultra-wide mesh belts.