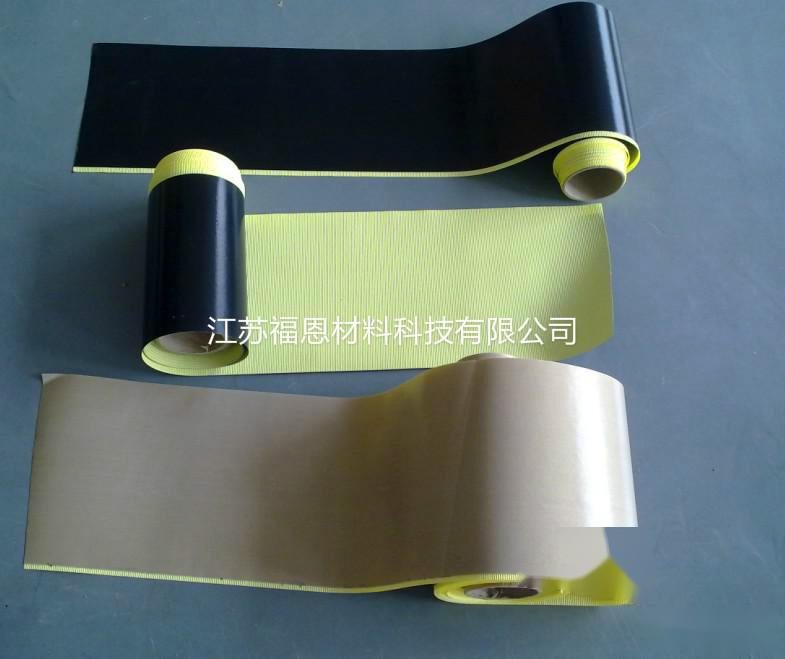

Jiangsu Fuen specializes in producing Teflon film adhesive tape, made from polytetrafluoroethylene (PTFE) molded raw materials, which are molded and sintered on a high-purity, dust-free production line. Using unique, fine, and high-precision processing technology, the PTFE (Teflon) film is produced as the adhesive tape substrate. After special surface treatment, one side is coated with a layer of silicone resin pressure-sensitive adhesive to create a PTFE (Teflon) film adhesive or rolled pressure-sensitive self-adhesive tape.

Jiangsu Fuen specializes in producing Teflon film adhesive tape, made from polytetrafluoroethylene (PTFE) molded raw materials, which are molded and sintered on a high-purity, dust-free production line. Using unique, fine, and high-precision processing technology, the PTFE (Teflon) film is produced as the adhesive tape substrate. After special surface treatment, one side is coated with a layer of silicone resin pressure-sensitive adhesive to create a PTFE (Teflon) film adhesive or rolled pressure-sensitive self-adhesive tape.

◆Main Features:

1. Smooth surface, good wear resistance.

2. Acid resistant, alkali resistant, and corrosion resistant.

3. Temperature resistance: -70℃ to +260℃ (continuous)

4. Elongation rate: Voltage breakdown: 25KV

◆Product Parameters:

|

Model |

Thickness |

Maximum Width |

Adhesion Strength (to Steel) |

Tensile Strength |

Temperature Resistance (℃) |

|

M3008 |

0.08MM |

600MM |

20N/100MM |

300N/100MM |

-70℃-260℃ |

|

M3013 |

0.13MM |

600MM |

22N/100MM |

350N/100MM |

-70℃-260℃ |

|

M3025 |

0.25MM |

600MM |

48N/100MM |

800N/100MM |

-70℃-260℃ |

|

M3035 |

0.35MM |

600MM |

58N/100MM |

950N/100MM |

-70℃-260℃ |

|

M3018 |

0.18MM |

1250MM |

25N/100MM |

650N/100MM |

-70℃-260℃ |

◆Application Industries:

Widely used in wind blade components, composite material mold release, high-temperature, acid and alkali resistant, non-stick thermal conductive rollers, low surface friction protection for heating plates, plastic mold workpiece release, high-temperature high-pressure cable insulation wrapping, electronic component high-temperature soldering protection, and electronic material die-cutting.