Teflon high-temperature fabric, special Teflon high-temperature fabric, and polytetrafluoroethylene high-temperature fabric are high-performance, multi-purpose composite materials made from a suspension of polytetrafluoroethylene (commonly known as the king of plastics) emulsion, which is impregnated into high-performance glass fiber fabric.

Teflon high-temperature fabric, special Teflon high-temperature fabric, and polytetrafluoroethylene high-temperature fabric are high-performance, multi-purpose composite materials made from a suspension of polytetrafluoroethylene (commonly known as the king of plastics) emulsion, which is impregnated into high-performance glass fiber fabric.

Features of Special Teflon High-Temperature Fabric:

The high-temperature fabric is used between low temperature -196℃ and high temperature 300℃, with good weather resistance and anti-aging properties. In practical applications, such as being continuously placed at 250℃ for 200 days, it maintains its strength without any reduction, and its weight does not decrease; at 350℃, after being placed for 120 hours, its weight only decreases by about 0.6%; at ultra-low temperature -180℃, it does not crack and retains its original flexibility. It has non-stick properties: it is difficult to adhere to any substances. It is easy to clean various oils, stains, or other attachments from its surface; adhesives, resins, coatings, and almost all adhesive substances can be easily removed; it is resistant to chemical corrosion and can withstand strong acids, strong bases, aqua regia, and various organic solvents. The friction coefficient is low (0.05-0.1), making it a choice for oil-free self-lubrication. Its light transmittance reaches 6-13%. It has high insulation properties (low dielectric constant: 2.6, tangent below 0.0025), UV protection, and anti-static properties. It has good dimensional stability (elongation coefficient less than 5‰) and high strength. It possesses good mechanical properties. It is resistant to agents and non-toxic. It can withstand almost all chemical agents.

Main Uses

Glass FibercoatingPolytetrafluoroethyleneproducts, due to their excellent performance, are widely used in aviation, papermaking, food, environmental protection, dyeing, clothing, chemicals, glass, pharmaceuticals, electronics, insulation, construction (roof membrane structure base cloth), grinding wheel cutting slices, machinery, and other fields. It can be used for corrosion-resistant coatings, linings and pads, non-stick conveyor belts, high-frequency copper-clad boards, building membrane materials, insulation materials, microwave drying conveyor belts, flexible compensators, friction materials, etc., for heating food gaskets, baking sheets, microwave gaskets, and microwave drying belts. In the plastic and rubber fields, it is used for anti-stick liners, gaskets, and covers, as well as applications in carpet belts. Depending on the thickness, it can be used for various drying machine conveyor belts, such as for drying medicinal materials, tea leaves, food, chemicals, etc., bonding belts, sealing belts, and so on. Used for corrosion-resistant wrapping of various petrochemical pipelines, insulation and temperature-resistant wrap materials for electronic appliances, and environmental desulfurization for power plant exhaust.

Main Varieties Introduction

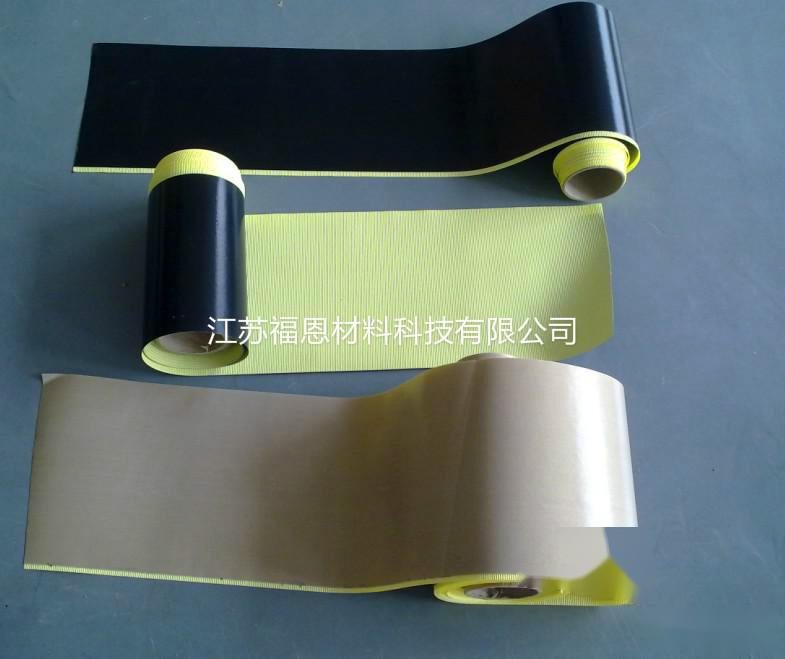

1. Teflon high-temperature paint cloth (high-temperature welding cloth) for insulation materials used in copper-clad boards (polytetrafluoroethylene, PTFE, Teflon, Special Teflon)

2. Teflon mesh conveyor belt (polytetrafluoroethylene, PTFE, Teflon, Special Teflon)

3. Teflon adhesive tape (polytetrafluoroethylene, PTFE, Teflon, Special Teflon)

4. Teflon bonding machine belt, seamless bonding machine belt (polytetrafluoroethylene, PTFE, Teflon, Special Teflon)

5. Kevlar Teflon mesh fabric

6. Teflon baking sheets, silver powder baking sheets, baking baskets, food-grade packaging bags, blast furnace gaskets, microwave gaskets

7. Glass fiber grinding wheel mesh sheets, various bullnose joints