Sewage Pump,Self-priming Sewage Pump,Non-blocking Sewage Pump,Submersible Sewage Pump,Vertical Sewage Pump,Self-priming SewagePump

ZW type Self-priming Sewage Pump, also known as solid-liquid Pump or impurity Pump. This series of Pumps has a unique hydraulic design, with the impeller enclosed in a separate impeller chamber, connected to the pressure chamber. When the impeller rotates, a strong axial vortex is generated in the Pump, creating a vacuum at the inlet and generating lift at the outlet. As a result, impurities can be expelled from the pressure chamber, ensuring a completely unobstructed flow path, making its sewage discharge effect unmatched by other self-priming sewage pumps. The ZW self-priming vortex non-blocking Sewage Pump produced by our unit does not require the installation of a foot valve like a typical self-priming clean water pump, and can pump wastewater containing large solid particles, long fibers, sediments, waste mineral impurities, fecal matter, and all types of engineering sewage. It is widely applicable in municipal sewage engineering, light industry, papermaking, textiles, food, chemical, electric power, petroleum, mining, and aquaculture sectors. It is currently an ideal impurity Pump for transferring solid particles, fibers, slurries, and mixed suspensions. Performance range flow Q: 8~800 m³/h, diameter DN: 25~300mm, lift H: 15~80m, speed N: 2900~1450r/min, motor power: 1.5~55kw.

ZW type Self-priming Non-blocking Sewage Pump is a new type of pump developed by our company based on the structure and performance of ZX type Self-priming Centrifugal Pump and QW type Submersible Sewage Pump, incorporating the advantages of similar foreign products. It combines self-priming and sewage discharge functions, allowing it to operate like a typical clean water self-priming pump without requiring a foot valve or priming water. It can pump sewage containing large solid particles with a diameter of up to 60% of the outlet diameter and fibers with lengths up to 1.5 times the impeller diameter, as well as sediments, waste mineral impurities, fecal matter, all types of engineering sewage, and colloidal liquids, significantly reducing labor intensity while being easy to install and use, requiring minimal maintenance, and achieving performance at an internationally advanced level, with a broad application market and development prospects.

All our products are designed and optimized using computer technology. The company possesses strong technical capabilities, rich production experience, and complete testing means, ensuring the stability and reliability of product quality.

II. Self-priming Non-blocking Sewage Pump Application:

Applicable to chemical, petroleum, pharmaceutical, mining, papermaking, fiber, slurry, textile, food, power plant, municipal sewage engineering, public facility sewage, aquaculture in rivers and ponds, and other industries.

1. Ambient temperature ≦50℃, medium temperature ≦80℃ with special requirements can reach 200℃.

2. Medium pH value: cast iron material is 6-9, stainless steel is 2-13.

III. Self-priming Non-blocking Sewage Pump Product Advantages:

1. Strong sewage discharge capacity: Special impeller anti-blocking design ensures the pump operates efficiently and without blockage.

2. High efficiency and energy saving: Hydraulic modeling is used, providing 3-5% higher efficiency than general self-priming pumps.

3. Good self-priming performance: Self-priming height is 1 meter higher than that of general self-priming pumps, and self-priming time is shorter.

IV. Self-priming Non-blocking Sewage Pump Technical Parameters:

Flow: 5-800 m³/h;

Lift: 12-60 m;

Motor Power: 2.2-55 KW;

Speed: 1450-2900 r/min;

Diameter: φ25-φ300;

Medium Temperature: ≤100℃;

Self-priming Height: 4.5-6.0 m.

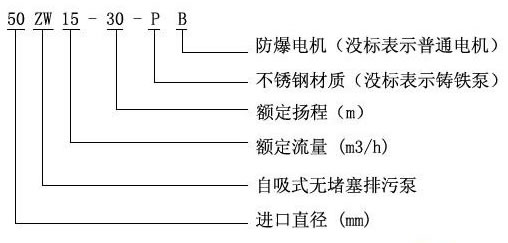

V. Self-priming Non-blocking Sewage Pump Model Significance: