This production line adopts new technology, fully mixing PVC, PP, PE, PS, and other plastics with plant fibers. It uses efficient conical twin-screw extrusion, equipped with a forced cooling system for extrusion molding. The produced wood-plastic boards are environmentally friendly, moisture-proof, anti-corrosive, and do not deform. They are suitable for wood processing methods and can be recycled repeatedly. Performance features: ◆ JG-MSB series of specialized extrusion equipment for wood-plastic boards, equipped with a DC motor drive that offers stable output and high torque, American ETD or Parker speed controllers, ensuring stable performance, energy efficiency, and high extrusion output. ◆ The screw core cooling uses an oil constant temperature system, ...

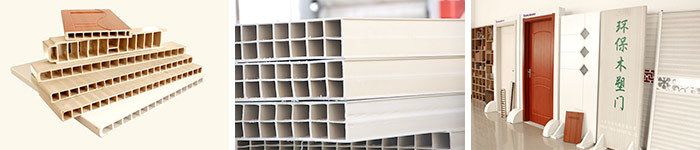

This production line adopts new technology, fully mixing PVC, PP, PE, PS, and other plastics with plant fibers. It uses high-efficiency conical twin-screw extrusion, equipped with a forced cooling system for extrusion molding. The produced wood-plastic boards are environmentally friendly, moisture-proof, anti-corrosive, and do not deform. They are suitable for wood processing methods and can be recycled and reused.

Performance Characteristics:

◆ TJ-MSB series wood-plastic board dedicated extrusion equipment, equipped with a DC motor drive that offers stable output and high torque, American ETD or Parker speed controllers, ensuring stable performance, energy efficiency, and high extrusion output.

◆ The core of the screw adopts an oil constant temperature system for automatic temperature control, ensuring that the material reaches a good plasticization state. A vacuum exhaust barrel is used to allow full evaporation of moisture in the material, ensuring product quality.

Brand low-voltage electrical appliances, with precise control and easy operation. Optional high-end programmable computer control is also available, achieving full-line intelligence.

◆ Vacuum sizing table, specially designed cooling system, for easy product cooling and shaping.

Main Technical Parameters

Model | TJ-MSB80/156 | TJ-MSX92/188 | |

Screw diameter | mm | Φ80/156 | Φ92/188 |

Number of screws | 2 | 2 | |

rotational speed | r/min | 1-38 | 1-32.9 |

Main machine power | KW | 55 | 110 |

Heating Power (approx.) | KW | 36 | 45 |

Extrusion output | kg/h | 200-400 | 300-550 |

Model | BF800 | BF1000 | |

Product dimensions | mm | 800 | 1000 |

Haul-off height | mm | 150 | 150 |

Traction | KN | 50 | 50 |

牵引速度 Haul-off speed | m/s | 0-3 | 0-2.5 |

Total Power of Auxiliary Machines | KW | 35 | 40 |

cooling water capacity | m3/h | 9 | 12 |

Compressed air pressure | Mpa | 0.6 | 0.6 |

Widely used in wide door panels, partition boards, construction formwork, container floors, and home decoration suite doors.

Whats App

Whats App

Plastmatch App

Scan the QR code

Plastmatch App

Scan the QR code 1000+ Daily Updated Global Business Leads,2M+ Global Company Database.Click to download the app.

Purchase request Download app