This production line can simultaneously and efficiently extrude four PVC pipes, saving energy, space, and human resource costs. The cutting system uses a new no-chip cutting method for PVC pipes, ensuring a smooth and burr-free cut; the PLC computer control ensures high cutting accuracy. The entire machine adopts intelligent distributed control, making it easy to operate with a high level of automation, ensuring stable and reliable production.

Equipment Parameters

| Machine model | TJ-CXG51/105-2 | TJ-CXG65/132-4 | |

| Extruder | mm | Φ51/105 | Φ65/132 |

| Number of cavities | pcs/team | one out two | One out four |

| Driving power | r/min | 15 | 37 |

| Pipe diameter range | pcs | Φ16-Φ32 | Φ16-Φ32 |

| Vacuum sizing box length | mm | 4 | 4 |

| Overall dimensions (approx.) | kg/h | 17×2×4 | 20×2×4 |

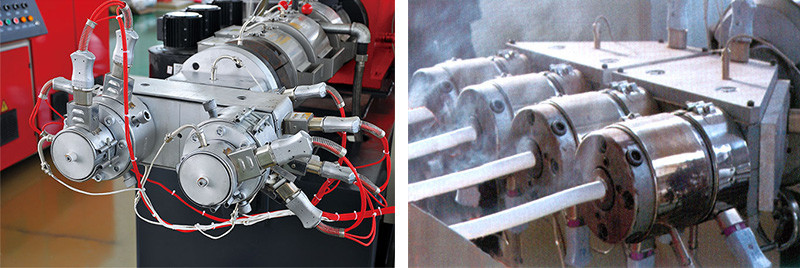

Equipment Display

Product Applications

Whats App

Whats App

Plastmatch App

Scan the QR code

Plastmatch App

Scan the QR code 1000+ Daily Updated Global Business Leads,2M+ Global Company Database.Click to download the app.

Purchase request Download app