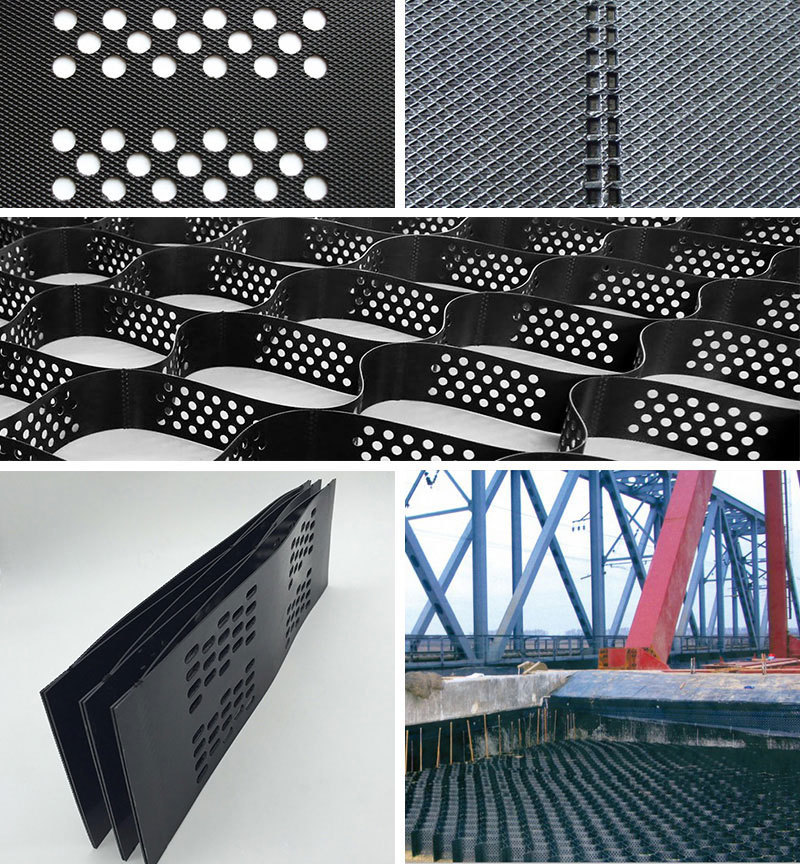

This production line is used for manufacturing geocells, a type of geosynthetic product that forms a honeycomb-like three-dimensional structure when thermoplastic sheets are connected and expanded through methods such as ultrasonic welding. The unique three-dimensional structure of the geocells can form layers with varying cohesion, reinforcement strength, and thickness when combined with fillers like soil, sand, and gravel. They are widely used in reinforcing the foundations of railways and roads, slope protection, and constructing retaining walls.

| Model | TJ-TGGS90 | TJ-TGGS120 | TJ-TGGS150 | |

| Raw materials | PP/PE | PP/PE | PP/PE | |

| Sheet thickness | mm | 1----2 | 1---2 | 1--2 |

| Cell height | mm | 50,75,100,150,200 | 50,75,100,150,200,300 | 50.75.100.150.200.300 |

| Welding distance | mm | 340-800 | 340-800 | 340--800 |

| Sheet width | mm | 800 | 1200 | 2000 |

| Overall dimensions (approx.) | m | 28×5×3 | 30×7×3 | 35×9×3 |

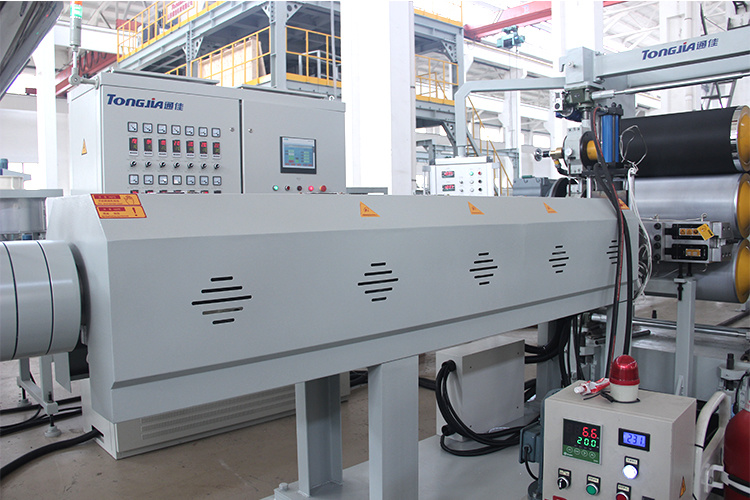

High-efficiency single-screw extruder

The extruder can continuously produce PP/PE thermoplastics.

High output, low power consumption, precise temperature control, and equipped with temperature protection function.

Large Diameter Three-Roll Calender

Adopting independent motor variable frequency speed control and gearbox drive, digital display dial indicator,

The entire machine adopts a motor and reducer for forward and backward movement.

Large diameter mirror finish three-roll system uses individually driven rollers, allowing for synchronized speed adjustment.

High-precision punching device

Gantry-type closed double-point high-performance press.

A closed-type fully welded frame eliminates the angular deformation phenomenon of open-type presses, improving the precision of stamping parts and extending the life of the mold.

Automatic winding device

Whats App

Whats App

Plastmatch App

Scan the QR code

Plastmatch App

Scan the QR code 1000+ Daily Updated Global Business Leads,2M+ Global Company Database.Click to download the app.

Purchase request Download app