POM•Polyoxymethylene(Delrin)

POM•Polyoxymethylene(Delrin)English Name: Polyformaldehyde, Abbreviation: POM or Acetal. Polyoxymethylene is a high melting point, high crystallinity plastic. It can be classified into copolymer and homopolymer, with POM-C copolymer widely used in semi-finished products on the market. Due to its excellent comprehensive properties and smooth, glossy surface, POM is particularly suitable for precision machining and manufacturing precision parts. It can be used for long periods within a temperature range of -40 to 100°C.

Copolymers of polyoxymethylene (POM-C) have stronger hydrolysis resistance, resistance to strong alkalis, and thermal oxidative degradation resistance compared to homopolymer formaldehyde. Homopolymer polyoxymethylene (POM-H) has higher mechanical strength, stiffness, hardness, and creep resistance than POM-C, as well as a lower coefficient of thermal expansion and better wear resistance.

Delrin® AF is a blend of POM-H and PTFE. It is softer than pure POM-H, has reduced stiffness, and is smoother. This material provides excellent sliding performance.

Superior Characteristics:

· High mechanical strength, stiffness, and hardness

· Toughness and good creep resistance

· High impact strength even under low-temperature conditions

· Low water absorption and good dimensional stability

· Good sliding performance and wear resistance

· Good electrical insulation and dielectric properties

· Excellent machinability

· Physiologically inert, can be in contact with food

· Good oil resistance and peroxide resistance.

Disadvantages:

· Not resistant to acids or strong alkalis

· Not resistant to sunlight and ultraviolet radiation

· Non-flame-retardant, cannot be near fire.

Application Range:

POM is widely used in the manufacture of various sliding and rotating machinery and precision parts such as rollers, guide wheels, gears, bearings, shaft sleeves, fixtures, levers, handles, etc. It is utilized in industries such as automotive, electronics, garment, medical, machinery, and sports equipment.

Common Stock Specifications:

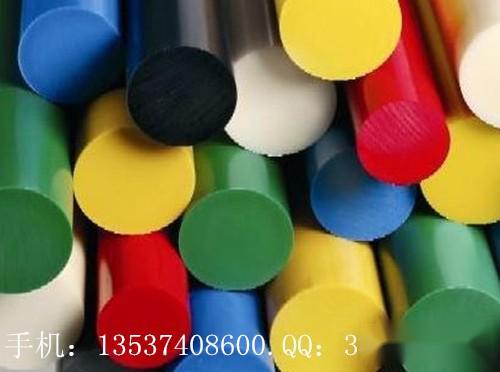

Sheet: (0.5-1)x 1000 x 50M; (1-60)x 1000 x 2000mm; (8-150)x 610 x 1220mm;

Round Rod: (5-250)x 1000mm;

Round Tube: (25-500)x (10-375)x 1000mm

Colors: White, black. Other colors can be custom produced.

Modified Products: Enhanced sliding (Delrin® AF), antistatic, glass fiber reinforced, POM+PE, medical grade, etc.