This unit is a polyolefin heat shrink film blowing machine developed by our company using advanced technology, featuring a dual-bubble forming method. It is equipped with a high-efficiency BM split-type screw, a spiral tube combined die, and other high-tech products such as a rotating winder. The product boasts superior physical properties, including high transparency, strong flexibility, excellent cold resistance, high tensile strength, and a high shrinkage rate. It is widely used in the packaging of food, beverages, medicine, health supplements, audio-visual products, electrical components, small machinery, and export goods.

↵

Equipment Parameters

| Machine Model | unit | TJ-RSM5B1300 | TJ-RSM5B1800 | TJ-RSM5B2200 |

| Applicable Materials | PP/PE and additives | PP/PE and additives | PP/PE and additives | |

| Film layflat width | mm | 1200 | 1600 | 2000 |

| Film thickness | mm | 0.015-0.025 | 0.015-0.025 | 0.015-0.025 |

| Output Production | kg/h | 80-120 | 100-120 | 120-200 |

| Inner and outer screw diameters | mm | Ø45×2 | Ø55×2 | Ø65×2 |

| Screw length-to-diameter ratio | L/D | 30:01:00 | 30:01:00 | 30:01:00 |

| Inner and outer layer motor power | KW | 11×2 | 15×2 | 37×2 |

| Inner and Outer Layer Heating Power | KW | 10×2 | 12×2 | 17.5×2 |

| intermediate layer screw diameter | mm | Ø65 | Ø80 | Ø90 |

| Screw length-to-diameter ratio | L/D | 30:01:00 | 30:01:00 | 30:01:00 |

| Intermediate layer motor power | KW | 37 | 45 | 55 |

| Intermediate layer heating power | KW | 16 | 25 | 32 |

| Die head heating power | KW | 30 | 35 | 38 |

| Total installed power (approx.) | KW | 160 | 190 | 290 |

| Average energy consumption (approx.) | KW | 90 | 100 | 160 |

| Overall dimensions (approx.) | m | 16×7.5×13.5 | 18×10×15 | 20×11×16 |

| Machine weight (approx.) | T | 28 | 38 | 55 |

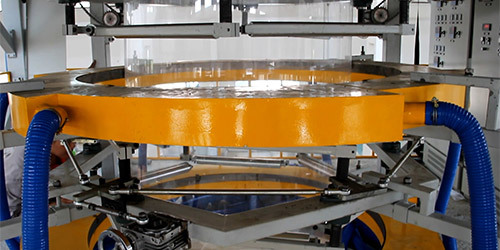

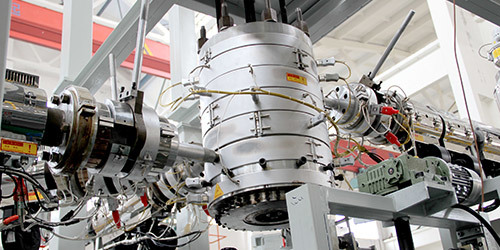

Equipment Display

Whats App

Whats App

Plastmatch App

Scan the QR code

Plastmatch App

Scan the QR code 1000+ Daily Updated Global Business Leads,2M+ Global Company Database.Click to download the app.

Purchase request Download app