The PET/PLA extrusion sheet production line is a novel, crystallization-free and drying-free extrusion sheet production line developed by our company through the absorption of international advanced technology and the integration of multiple production process formula systems. It adopts precision three-roll calendaring technology and a patented twin-screw compound extruder, which reduces the viscosity of the raw materials, improves cooling efficiency, and significantly enhances the quality and output of the sheets. The production line features green environmental protection, low energy consumption, simple processes, convenient operation, compact structure, superior performance, uniform plasticization, stable extrusion, and high output...

| Machine Model | TJ-JC75 | TJ-JC85 | |

| Extruder | 75mm Parallel Twin-screw | 85mm Parallel Twin-screw | |

| Product width | mm | 800-1100 | 800-1500 |

| Product thickness | mm | 0.12-1.6 | 0.12-1.6 |

| Production capacity (approx.) | Kg/h | 350-500 | 400-600 |

| Installed capacity (approx.) | kw | 295 | 365 |

| Overall dimensions (approx.) | m | 20×6×6 | 22×6×6 |

| Machine weight (approx.) | t | 15 | 20 |

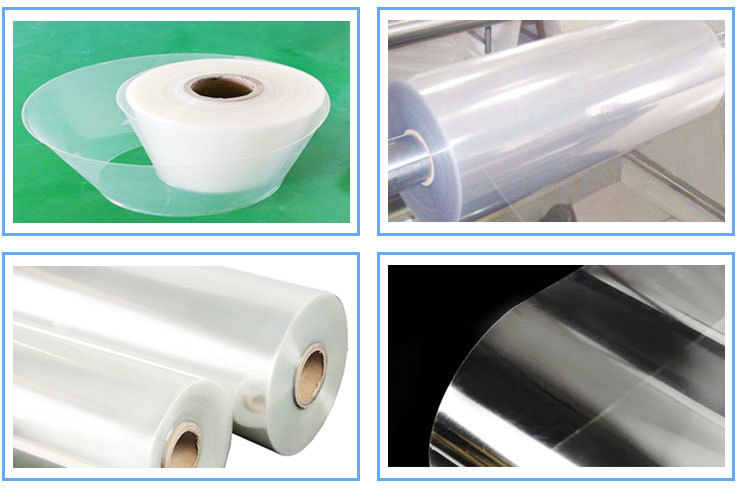

Product Applications

PET extruded sheets are widely used in the vacuum forming field: food packaging, toy boxes, stationery boxes, gift boxes, and packaging for tools, fruits, hardware, etc.

In the field of antistatic applications: packaging for electronic components, permanent conductive sheets, permanent antistatic sheets, and permanent semiconductive sheets; in daily life applications: blister packaging, folding boxes, packaging, printing, and card manufacturing industries.

Whats App

Whats App

Plastmatch App

Scan the QR code

Plastmatch App

Scan the QR code 1000+ Daily Updated Global Business Leads,2M+ Global Company Database.Click to download the app.

Purchase request Download app