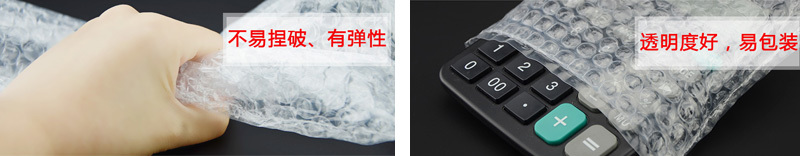

PE air cushion film (also known as polyethylene bubble film, bubble wrap, or bubble paper) is a commonly used traditional packaging material. It not only has excellent shock absorption, impact resistance, and heat sealing properties but also features good corrosion resistance and transparency. By adjusting the process and adding equipment, it can be produced into functional composite packaging products with up to seven or even more layers. It is widely used in various fields such as electronics, precision instruments, daily necessities, glass, ceramics, home appliances, furniture, hardware products, and toys.

Equipment Parameters

| Project | PE Two-layer Composite Air Cushion Film Machine | Three-layer PE composite air cushion film production line | |||

| Model | TJ-QDM65E | TJ-QDM90E | TJ-QDM65S | TJ-QDM90S | |

| Screw diameter | mm | Φ65 | Φ90 | Φ65/45 | Φ90/65 |

| aspect ratio | L/D | 25:01:00 | 25:01:00 | 25:01:00 | 25:01:00 |

| screw speed | r/min | 5-40 | May 30th | 5-40 | May 30 |

| Bubble specifications | mm | (5-30)×(3-10) | (5-30)×(3-10) | (5-30)×(3-10) | (5-30)×(3-10) |

| Product width | mm | 600-1200 | 600-2500 | 600-1200 | 600-2500 |

| Installed capacity (approx.) | KW | 40 | 60 | 75 | 110 |

| Overall dimensions (approx.) | m | 8×2.5×2.5 | 10×3×2.8 | 8×7×2.5 | 12×10×2.5 |

| Machine weight (approx.) | T | 3 | 6 | 5 | 9 |

Product Applications

Whats App

Whats App

Plastmatch App

Scan the QR code

Plastmatch App

Scan the QR code 1000+ Daily Updated Global Business Leads,2M+ Global Company Database.Click to download the app.

Purchase request Download app