One. Overview

CDLK/CDLKF is a self-priming vertical multi-stage centrifugal submersible pump for standard motor installation, the motor shaft is directly connected to the pump shaft through a coupling on the pump head, the pump can be equipped with intelligent protector as needed to effectively protect against dry running, phase loss, overload, etc. To meet the installation depth of water tanks or containers, an empty cavity can be installed to change the length of the pump itself, different stages of lengths can be seen in the dimensions and weight table and the range of products available.

Two. Application Range

CDLK/CDLKF is used for conveying machine tool cooling liquid, lubricating liquid, condensate transport, industrial cleaning equipment, and other occasions suitable for submersible pump use, suitable for different temperature, flow, and pressure ranges, CDLK is suitable for non-corrosive liquids, CDLKF is suitable for slightly corrosive liquids.

Specifically used for EDM machines, lathes, grinders, machining centers, cooling devices, industrial cleaning equipment, filtration systems, etc.

Three. Motor

The motor is fully enclosed, air-cooled two-pole standard motor.

Protection class: IP55

Insulation class: F

Standard voltage: 50Hz:1*220-230/240V

3*200/346V

3*220-240/380-415V

3*220-225/380-440V

Other voltages for motors are available as required.

Single-phase voltages from 0.37-2.2kw are available.

Four. Operating Conditions

Dilute, clean, non-explosive liquids without solid particles and fibers, can convey water and cooling water solutions and cutting lubricants.

Liquid temperature: normal temperature type -15°C~+70°C

hot water type +70°C~+120°C

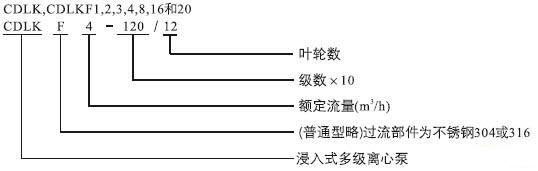

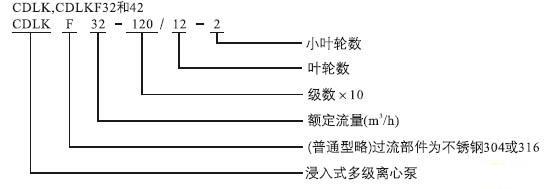

Five. Model Meaning

Six. Performance Curve

1. All curves are based on measurements of the motor at a constant speed of 2900r/min.

2. Curve tolerance complies with ISO9906, see performance curve chart.

3. Testing uses 20°C air-free water with a dynamic viscosity of 1mm2/s.

4. When using the pump, refer to the bold line for the performance range to prevent overheating due to excessive flow and motor overload due to excessive flow.

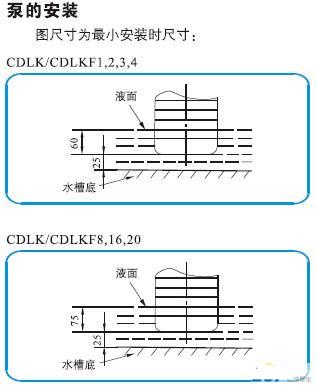

Seven. Pump Installation