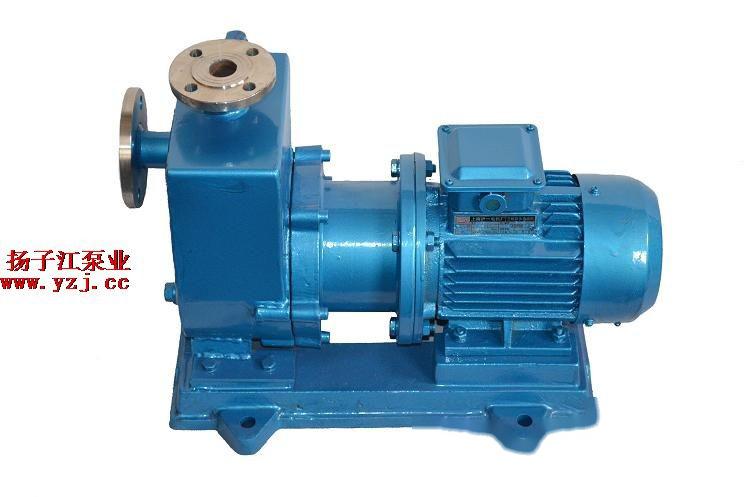

ZCQ Magnetic Pump;ZCQMagnetic Pump

Product Overview

The ZCQ type Self-priming Magnetic Pump (hereinafter referred to as Self-priming Pump) is a new product developed based on the CQ type magnetic pump, incorporating advanced foreign technologies as per user requirements, and has been successfully researched and tested by our engineering technicians. Its performance reaches the advanced level of similar foreign products from the 1990s. This pump replaces mechanical seals with static seals, ensuring that the pump's flow components are completely sealed, effectively eliminating the issues of leakage inherent in other pumps with mechanical seals. The materials used for the pump body and flow components are made of corrosion-resistant stainless steel, steel-ceramic, and polytetrafluoroethylene, thus combining the functions of the CQ type magnetic drive pump with self-priming capabilities, eliminating the need for a foot valve and priming water, with a self-priming height of 4 meters.

The main features of the ZCQ type Self-priming Magnetic Pump

The ZCQ type magnetic self-priming pump has a compact structure, attractive appearance, small size, low noise, reliable operation, and is easy to maintain. It can be widely used in petroleum, chemical, pharmaceutical, electroplating, dyeing, food, scientific research, and other units for transferring acids, alkalis, oils, rare valuable liquids, toxic liquids, volatile liquids, as well as for supporting circulating water equipment, especially for transferring liquids that are prone to leakage, flammability, and explosiveness. Therefore, it has a wide range of applications, and we sincerely recommend this product to users.

Meaning of ZCQ type Self-priming Magnetic Pump model designation

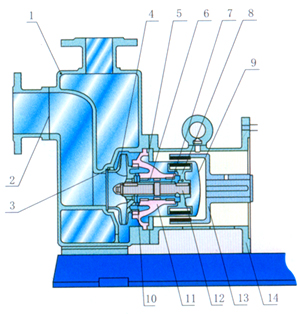

Structural diagram of ZCQ type Self-priming Magnetic Pump

Installation and Usage

1. After unpacking, check the pump nameplate to verify that the main parameters of the self-priming pump meet the usage requirements.

2. The self-priming pump should be installed horizontally, and the pump body should not bear the weight of the pipeline.

3. The pump and pipeline should maintain good sealing.

4. The pump should be inspected before use; the motor fan must rotate flexibly without any obstruction or abnormal noise, and all fasteners should be secure.

5. Unscrew the water filling bolt on the top of the pump, add liquid to about two-thirds of the pump body volume, and tighten the bolt.

6. Connect the power supply and briefly test the pump to ensure that the rotation direction matches the pump rotation mark when viewed from the motor end.

7. Before stopping the pump, first close the discharge valve, then turn off the power, and finally close the suction pipe valve.

Precautions for using the ZCQ type Self-priming Magnetic Pump

1. Since the cooling and lubrication of the magnetic pump bearing relies on the medium being transported, it is prohibited to run the pump in dry conditions, and to avoid running without load after a power failure during operation.

2. If the medium being transported contains solid particles, a filter screen must be added at the pump inlet; if it contains ferromagnetic particles, a magnetic filter must be added.

3. The environmental temperature during pump operation should be less than 40℃, and the motor temperature rise should not exceed 75℃.

4. The medium being transported and its temperature should be within the allowable range of the pump materials (see the attached table for details). The operating temperature of the metal pump should be <100℃, and the specific gravity of the medium should be ≤1.3; if the specific gravity is <1.3, it will affect the technical performance.

5. For media that are prone to sediment or crystallization, the pump should be cleaned promptly after use, and any residual liquid inside the pump should be drained.

6. After 500 hours of operation, the bearings and the wear condition of the end face dynamic ring should be inspected. If the clearance between the bearing and the shaft sleeve exceeds 0.5-1mm, or the axial movement of the impeller is 0.5-2mm, the bearings and axial dynamic ring should be replaced.