1.Magnetic Drive Pump Overview

The CQ stainless steel magnetic pump is a new type of pump that transmits torque without contact using the working principle of a permanent magnet coupling. When the prime mover drives the outer magnetic rotor, the inner magnetic rotor is driven to rotate synchronously through the action of the magnetic field. The inner magnetic rotor is integrated with the impeller, achieving the purpose of driving the impeller to rotate without contact. As the liquid is sealed within a stationary isolation sleeve, the magnetic pump is a fully enclosed, leak-free pump type, completely eliminating the drawbacks of running, leaking, dripping, and oozing that are inevitably present in mechanically sealed centrifugal pumps.

In many fields such as petroleum, chemical, pharmaceutical, electronics, and more, an increasing number of manufacturers require a leak-free process environment for the media being transported, urgently needing to choose an ideal pump type. Our company’s CQ series magnetic pumps absorb new technologies, materials, and processes for magnetic pumps production from both domestic and international levels, successfully solving the current technical problems of component damage, such as isolation sleeves and impellers, in domestic magnetic drive pumps, thus enhancing their performance. The CQB, IMD, CQ, and CQF series magnetic pumps have been continuously tested in production by users for an extended period, leading more and more users to be confident that they have chosen a safe and reliable pump type. We will continue to provide better services to our users.

2.Magnetic Drive Pump Applications

The flow components of the CQ series stainless steel magnetic pumps are made of stainless steel (304, 316, 316L) and are widely used in petroleum, chemical, pharmaceutical, electroplating, environmental protection, water treatment, national defense, and other sectors. They are ideal devices for transporting flammable, explosive, toxic, and precious liquids, making them the choice for creating a leak-free and pollution-free civilized workshop. The applicable temperature for magnetic drive pumps is -20℃ to 100℃.

3.Magnetic Pump Leak-proof Design

Static sealing replaces dynamic sealing, utilizing magnetic coupling for indirect drive, completely eliminating the worries of dripping and leakage, ensuring no pollution to the operating area. The magnetic drive pump is ideal for eliminating running, leaking, dripping, and oozing phenomena in chemical processes, reducing environmental pollution, and creating a "leak-free workshop" and "leak-free factory," thus achieving safe and civilized production.

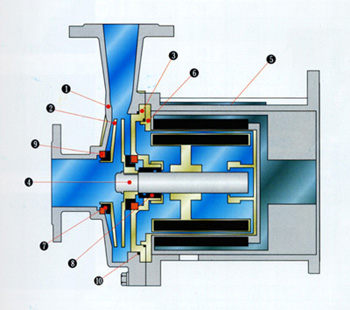

4.Magnetic Drive Pump Operating Principle

The drive device uses a driven magnetic coupling directly mounted on the motor shaft, and the pump chamber is completely sealed. The impeller on the rotor assembly is rotated indirectly through magnetic coupling.

5.Magnetic Drive Pump Structure and Materials

|

|

|