1.Stainless Steel Magnetic PumpProduct Overview:

CQ typeStainless Steel Magnetic Pump(referred to asMagnetic Pump) is a new product that applies the working principle of a permanent magnet coupling tocentrifugal pumps. It features a reasonable design and advanced technology, with characteristics of full sealing, no leakage, and corrosion resistance, achieving advanced performance levels comparable to similar foreign products.

2.Stainless Steel Magnetic PumpMain Features:

Magnetic Pumpuses static sealing instead of dynamic sealing, ensuring that the pump's flow components are in a completely sealed state, effectively solving the unavoidable issues of leakage associated with mechanical seals in other pumps.Magnetic Pumpis made from corrosion-resistant, high-strength engineering plastics, steel-ceramic composites, and stainless steel, thus offering excellent corrosion resistance and preventing contamination of the transported medium.

3.Stainless Steel Magnetic PumpProduct Applications:

The magnetic pump features a compact structure, attractive appearance, small size, low noise, reliable operation, and convenient maintenance. It can be widely used in chemical, pharmaceutical, petroleum, electroplating, food, national defense, research institutions, metallurgy, and dyeing industries for transporting acids, alkalis, oils, rare and precious liquids, toxic liquids, volatile liquids, as well as in supporting circulating water equipment and filtering machines. It is particularly suitable for pumping liquids that are prone to leakage, flammability, or explosion. Using an explosion-proof motor with this pump is an ideal choice.

5.Stainless Steel Magnetic PumpInstallation and Use

1. The magnetic pump should be installed horizontally and should not be vertical. The plastic pump body should not bear the weight of the piping. In special cases where vertical installation is required, the motor must be facing upwards.

2. When the suction liquid level is higher than the pump's centerline, simply open the suction pipeline valve before starting. If the suction liquid level is lower than the pump's centerline, the pipeline must be equipped with a bottom valve.

3. The pump should be checked before use. The motor impeller should rotate smoothly, without jamming or abnormal noises, and all fasteners should be tightened.

4. Check that the motor's rotation direction is consistent with the magnetic pump's rotation mark.

5. After the motor starts, slowly open the discharge valve. Once the pump reaches normal operating conditions, adjust the discharge valve to the desired opening.

6. Before stopping the pump, close the discharge valve first, then close the suction pipeline valve.

6. Precautions for Use

1. Since the cooling and lubrication of the magnetic pump bearings rely on the conveyed medium, dry running is prohibited, and care should be taken to avoid dry running caused by power outages during operation.

2. If the conveyed medium contains solid particles, a filter net should be added at the pump inlet; if it contains ferromagnetic particles, a magnetic filter must be added.

3. The ambient temperature during the pump's operation should be less than 40℃, and the motor temperature rise should not exceed 75℃.

4. The conveyed medium and its temperature should be within the allowable range of the pump material. The operating temperature for engineering plastic pumps is <60℃, for metal pumps <100℃, suction pressure should not exceed 0.2MPa, maximum working pressure is 1.6MPa, density not exceeding 1600 kg/m3, and particle size not exceeding 30 × 10-6 m²/S for liquids without hard particles and fibers.

5. For media that are prone to sediment crystallization, the pump should be cleaned immediately after use, and any liquid accumulated in the pump should be drained.

6. After 500 hours of operation, the bearings and the wear condition of the end-face dynamic rings should be checked. If the gap between the bearings and the shaft sleeve exceeds 0.5~1mm, or if the axial movement of the impeller exceeds 1.5~2mm, the bearings and the dynamic ring should be replaced.

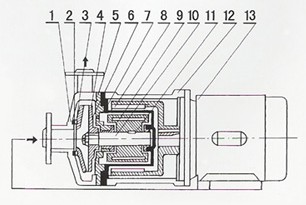

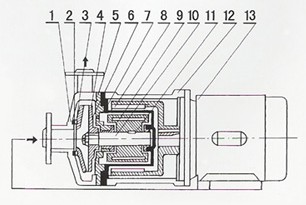

CQ TypeStainless Steel Magnetic Pump Structural Diagram

|

1

|

Pump Body

|

2

|

Static Ring

|

3

|

Dynamic Ring

|

4

|

Impeller

|

5

|

Seal Ring

|

6

|

Isolation Plate

|

7

|

Isolation Sleeve

|

|

8

|

Outer Magnetic Assembly

|

9

|

Inner Magnetic Assembly

|

10

|

Pump Shaft

|

11

|

Shaft Sleeve

|

12

|

Connecting Frame

|

13

|

Motor

|

14

|

|

|