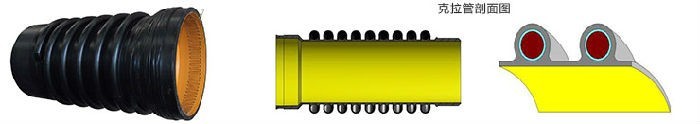

The production line uses high-density polyethylene (HDPE) resin as the main raw material, employing a hot-state winding forming process, with a polypropylene (PP) single-wall corrugated pipe as the supporting structure to form a winding B-type structural wall pipe with high resistance to external pressure, commonly known in China as Kela pipe (Baoku pipe). The inner surface of the pipe is smooth, and the exterior has a circular reinforced structure, featuring high ring stiffness and strong impact resistance. It uses thermal fusion sealing connections and is indeed a flexible pipe. The production line is equipped with a PLC control system, an intelligent human-machine interface, and is simple to operate.

Equipment Parameters

| Model | TJPE-2000 | TJPE-3000 | TJPE-4000 | |

| Pipe specifications | mm | Ø300-Ø2000 | Ø300-Ø3000 | Ø1500-Ø4000 |

| Maximum production speed | m/min | 0.35 | 0.35 | 0.1 |

| Total installed power | KW | 320 | 450 | 640 |

| Production line footprint | m×m | 38×16 | 38×16 | 38×16 |

Product Applications

Large-diameter polyethylene (PE) spiral wound structured wall pipes are a new type of irregular structured wall pipes, manufactured using the high-density polyethylene thermal winding process. The product is made from high-density polyethylene resin (HDPE) as the raw material, with PP or PE corrugated pipes serving as auxiliary support pipes, and is produced through a thermal winding process to create large-diameter, spiral-wound, reinforced HDPE pipes. Since this type of pipe was initially introduced to China by domestic companies from Krah AG in Germany, it is commonly known as Krah pipe in China.

Whats App

Whats App

Plastmatch App

Scan the QR code

Plastmatch App

Scan the QR code 1000+ Daily Updated Global Business Leads,2M+ Global Company Database.Click to download the app.

Purchase request Download app