Hydraulic Jet Ejector is a mechanical device with functions such as vacuum extraction, condensation, and drainage. It utilizes a certain water pressure to converge the water flow at a single focal point through a symmetrical and fixed inclined spray platform. Due to the high velocity of the ejected water flow, a negative pressure is formed around the water column, creating a vacuum inside the chamber. Additionally, the direct contact between the secondary vapor and the ejected water flow facilitates heat exchange, resulting in the condensation of most vapor into water. A small amount of uncondensed vapor and gas, due to friction with the ejected water flow, is mixed and expelled through a diffusion valve, further enhancing the vacuum within the chamber.

W-type Hydraulic Jet Ejector has a relatively simple structure, without mechanical transmission devices, resulting in low noise and convenient maintenance. It is equipped with a multi-stage pump that supplies water at low levels, providing stable working performance. The materials used for the hydraulic ejector include cast iron and stainless steel, making it suitable for vacuum evaporation systems in industries such as chemicals, pharmaceuticals, and food, used for processes like vacuum extraction, vacuum filtration, vacuum crystallization, drying, and deodorization.

Stainless steel hydraulic ejector is an ideal vacuum extraction device that is acid-resistant and corrosion-resistant.

Hydraulic Jet EjectorStructure and Advantages;

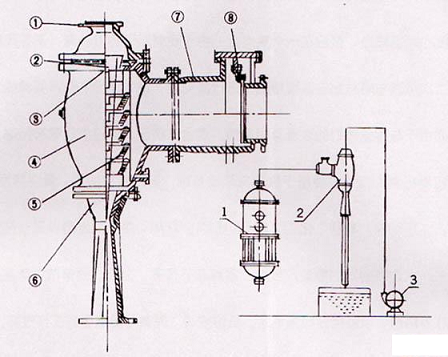

Hydraulic Jet Ejector consists of components such as the body, cover, nozzle, nozzle base plate, guide plate, diffuser, and check valve. The nozzle is made of stainless steel, the nozzle base plate is processed from steel, while the other parts are cast iron. The nozzle adopts a multi-nozzle structure to achieve a larger water-vapor contact area, facilitating heat exchange and achieving a better vacuum effect. The nozzle base plate is precisely machined with high accuracy to ensure that the ejected water flow accurately converges at the same focal point. The guide plate is used to slow down the flow rate of steam (or air), allowing the steam to enter the chamber uniformly and preventing the ejected water flow from deviating, thus reducing ejection efficiency. The entire device is compact, precise, and of high strength, used in vacuum evaporation systems, as it can combine the condensation effect of the condenser with the extraction action of the vacuum pump in one device, greatly simplifying the process flow. Compared to the original vacuum pump and the old-style condenser devices, it can save the vacuum pump, condenser, water separator, and other equipment, and has the following advantages: (1) The hydraulic ejector is small in size, light in weight, and compact in structure. Its efficiency is relatively high, with power consumption lower than that of the vacuum pump system, thus saving energy. (2) Simple operation and easy maintenance, requiring no dedicated personnel for management, and due to the absence of mechanical transmission components, it operates quietly without the need for lubricant consumption. (3) It can be installed outdoors at low positions, occupying less space, thus saving factory construction area and installation costs.

W Series Hydraulic Jet Ejector (Structural Diagram)