Sewage Pump,Self-Priming Sewage Pump,Non-Clog Sewage Pump,Submersible Sewage Pump,Vertical Sewage Pump,Pipeline Sewage Pump

The GW type vertical pipeline sewage pump is easy to install and has a wide range of applications. It can serve as a general pipeline pump for pressurizing water in high-rise buildings and can also transport sewage containing solid particles and fibers. In addition to conveying sewage, it is also suitable for use as a drainage pump, filter washing condenser circulating pump, etc. This series of pumps adopts a unique impeller structure and a new type of mechanical seal, effectively transporting media containing solids and long fibers. Compared to traditional impellers, the impeller of this pump adopts a single or double-channel design, resembling a bent pipe of the same cross-sectional area, which provides excellent flow properties, combined with a reasonable volute, resulting in high efficiency. The impeller undergoes dynamic and static balance testing, ensuring no vibration during operation.

1.Pipeline Non-Clog Sewage Pump Application Range

The GW series pipeline non-clog sewage pump is suitable for discharge of heavily polluted wastewater from factories and commercial establishments, sewage pumping stations in residential areas, urban sewage treatment plant distribution systems, civil defense system drainage stations, water supply equipment in water plants, sewage discharge in hospitals and hotels, municipal engineering construction sites, supporting equipment in mines, rural biogas tanks, agricultural irrigation, etc. It can transport sewage containing solid particles and can also be used for clean water and media with weak corrosiveness.

2.Pipeline Non-Clog Sewage Pump Operating Conditions

A. The operating environment temperature for the pipeline sewage pump should be ≤40℃, humidity ≤95%; altitude ≤1000 meters.

B. Medium temperature should not exceed 60℃, and medium density should be between 1–1.3kg/dm3.

C. The pH range for cast iron materials is 5–9.

D. Stainless steel materials can be used for general corrosive media.

E. The altitude of the operating environment should not exceed 1000 meters. If exceeding these conditions, please specify at the time of order to provide you with more reliable products.

Note: If users have special requirements for temperature, medium, etc., please specify the details of the transporting medium when placing the order, so that our company can provide more reliable products.

3.Pipeline Non-Clog Sewage Pump Product Features

1. The pump and motor are directly coupled on the same axis, making it a mechatronic product with a compact structure and stable performance.

2. The large flow channel design of the hydraulic components effectively increases the capacity for passing solids, capable of efficiently passing fibrous materials up to 5 times the pump diameter and solid particles with a diameter of approximately 50% of the pump diameter.

3. Reasonable design, appropriate motor matching, high efficiency, low noise, and significant energy-saving effects.

4. The mechanical seal uses hard-wearing tungsten carbide, which is durable and wear-resistant, allowing the pump to operate safely for over 8000 hours continuously.

5. The pump has a vertical structure, with the centerlines of the inlet and outlet on the same horizontal line, and the inlet and outlet flange specifications are the same, making installation and disassembly very convenient.

6. Small footprint, no need to build a machine room, saving a lot of infrastructure costs; a protective cover is added on the motor fan end, allowing the entire unit to operate outdoors.

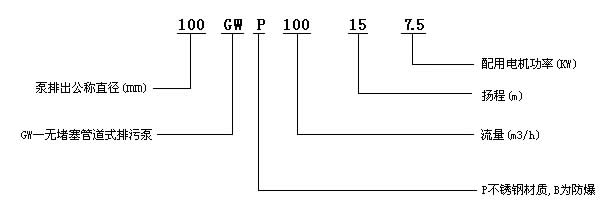

4.Pipeline Non-Clog Sewage Pump Model Significance:

The GW type pipeline sewage pump is easy to install and has a wide range of applications. It can serve as a general pipeline pump for pressurizing water in high-rise buildings and can also transport sewage containing solid particles and fibers. In addition to conveying sewage, it is also suitable for use as a drainage pump, filter washing condenser circulating pump, etc.

GW typepipeline sewage pump structure diagram: