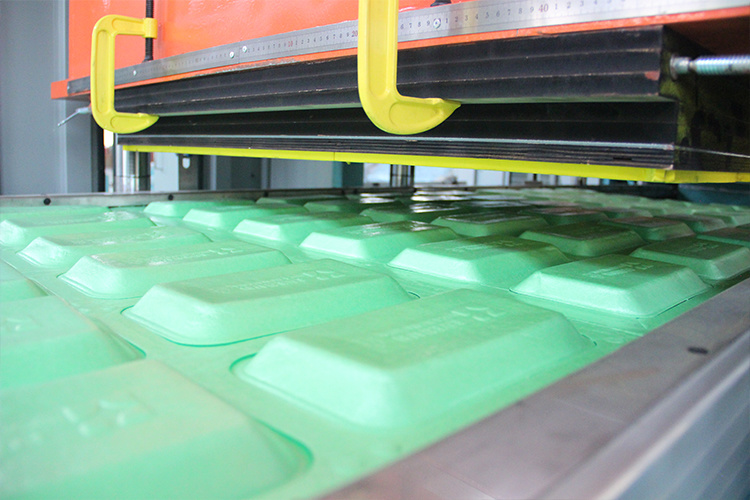

This machine adopts a full computerized digital forming system, with PLC-based mechatronic automatic control. It uses a touch screen to control various action programs, making it easy to operate, material-saving, and highly efficient in production. It features reliable stability, large forming area, ease of operation, fast forming speed, and high level of automation. This unit is a plastic sheet forming equipment that integrates feeding, heating, forming, punching, stacking, and edge trimming in one process. The machine is suitable for the forming of HIPS, PS, PP, PE, PVC, PET, and other plastic sheets, producing various packaging products such as boxes, trays, cups, bowls, and lids.

Equipment Parameters

| Machine model | TJ-ZXC600/900 | TJ-ZXC1100/1250 | |

| Sheet width | mm | 500-700 | 1000-1200 |

| Maximum molding area | mm | 600×900 | 1000×1200 |

| Maximum molding height | mm | 120 | 120 |

| Heating Power | kw | 53 | 100 |

| Production efficiency | Sec/mold | 3-5 | 3-5 |

| air source | mpa | 0.8-1 | 0.8-1 |

| Die Punch Installation Area | mm | 640×1080 | 1100×1250 |

| Effective punching area | mm | 620×900 | 1000×1200 |

| Maximum punching height | mm | 150 | 150 |

| Punching Pressure | T | 50 | 80 |

| Installed capacity (approx.) | kw | 90 | 200 |

| Overall dimensions (approx.) | m | 14×2.2×2.1 | 16×2.6×2.3 |

| Machine weight (approx.) | T | 8 | 12 |

Whats App

Whats App

Plastmatch App

Scan the QR code

Plastmatch App

Scan the QR code 1000+ Daily Updated Global Business Leads,2M+ Global Company Database.Click to download the app.

Purchase request Download app