Tongjia EPE foam sheet production line adopts a single-machine foaming process, using environmentally compliant butane as the foaming agent, resulting in products with high foaming ratio, white and fine texture. The electrical control system is carefully selected from well-known brands, featuring explosion-proof motors and variable frequency speed control, which is energy-efficient, safe, and stable. The temperature control system achieves intelligent digital display control and is equipped with a cooling circulation water system for direct cooling of the barrel, providing more precise temperature control and faster response. By changing the die head and corresponding auxiliary equipment, the Tongjia EPE foam sheet production line can also produce various foamed products such as foam tubes and rods, truly realizing multi-purpose functionality with one machine. Equipment composition: 1. Plasticizing and extrusion system; 2. Molding die head; 3...

| Model | TJ-FPM90 | TJ-FPM105 | TJ-FPM120 | TJ-FPM135 | TJ-FPM150 | TJ-FPM180 | TJ-FPM200 | |

| Extruder | Φ90/55 | Φ105/55 | Φ120/50 | Φ135/50 | Φ150/50 | Φ180/55 | Φ200/55 | |

| Screw speed | r/min | 5-75 | 5-75 | 5-75 | 5-60 | 5-60 | 5-50 | 5-50 |

| Foaming ratio | times | 20-45 | 20-45 | 20-45 | 20-45 | 20-45 | 20-45 | 20-45 |

| Product width | mm | 1000-1400 | 1000-1600 | 1000-1600 | 1000-1600 | 1000-2000 | 1000-2000 | 1000-2000 |

| Product thickness | mm | 0.5-3.0 | 0.5-5.0 | 0.8-6.0 | 2.0-8.0 | 2.0-12.0 | 3.0-16.0 | 3.0-25.0 |

| Cooling method | air cooling, water cooling | |||||||

| Installed capacity (approx.) | KW | 90 | 100 | 120 | 140 | 150 | 180 | 280 |

| Approximate Overall Dimensions | m | 22×2.3×2.2 | 23×2.3×2.2 | 25×2.3×2.2 | 27×2.5×2.3 | 30×2.5×2.3 | 32×2.5×2.3 | 36×2.8×2.5 |

| Machine weight (approx.) | T | 8.5 | 9 | 10 | 12 | 15 | 17 | 20 |

Equipment Advantages

Plasticizing Extrusion System

Well-known brand, high-end configuration, stable performance

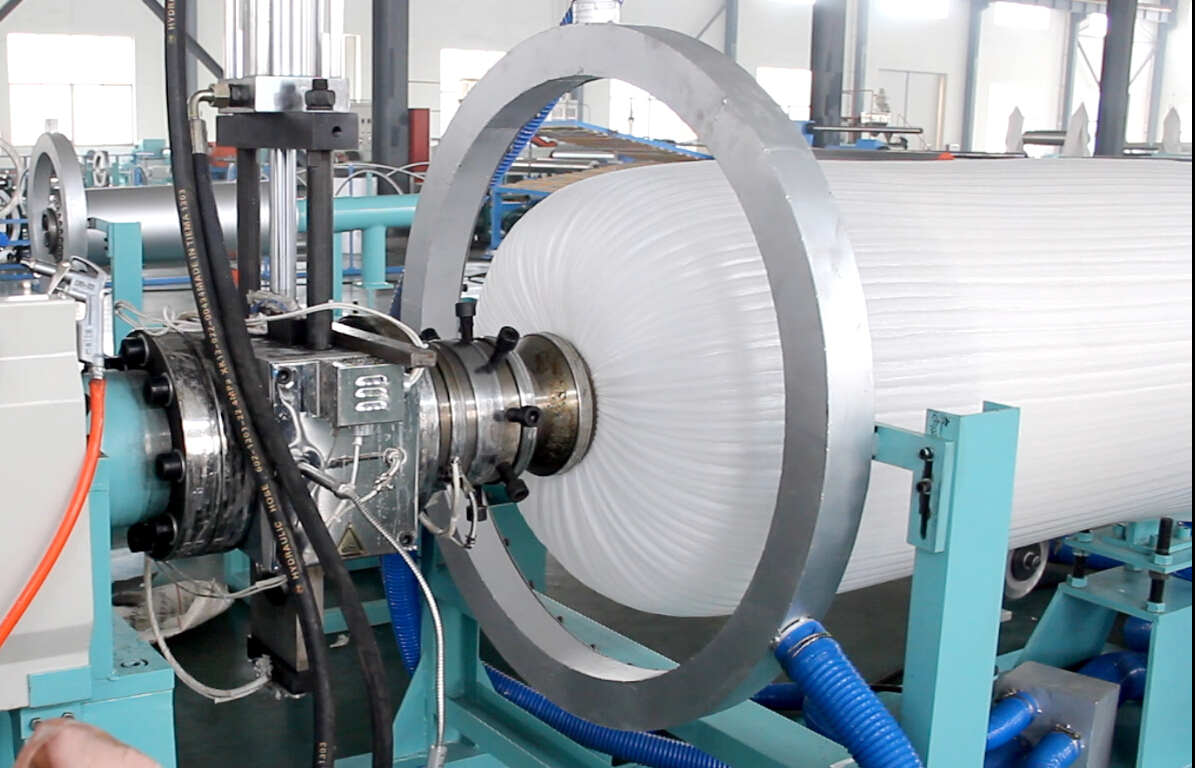

Die head system

Forged from high-strength alloy steel, precision machined

Cooling and Sizing System

Cooling circulating water, with precise temperature control and more responsive reaction

Traction system

Variable frequency speed control, with a width up to 3000mm

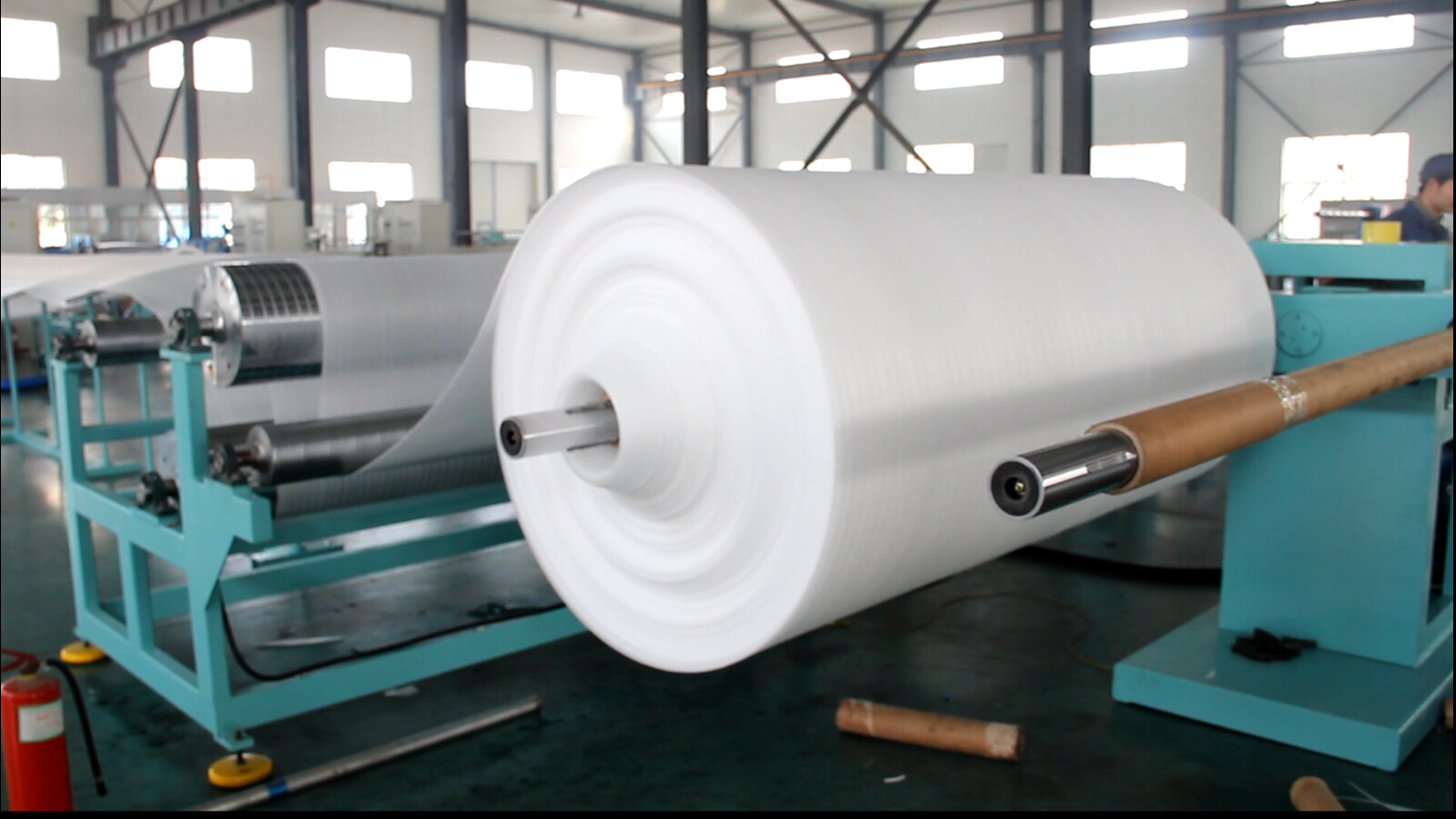

Winding system

Dual-station flip alternating winding, independently driven by motors

Product Applications

★ Inner packaging for daily necessities such as electronics, electrical appliances, instruments, medical devices, industrial control cabinets, lighting, crafts, glass, ceramics, household appliances, spray painting, furniture, gift packaging, hardware products, toys, and leather shoes

★ Industrial soundproofing and thermal insulation materials, agricultural thermal insulation materials, protective padding for sports equipment, and floor decoration for homes and hotels

Whats App

Whats App

Plastmatch App

Scan the QR code

Plastmatch App

Scan the QR code 1000+ Daily Updated Global Business Leads,2M+ Global Company Database.Click to download the app.

Purchase request Download app