The XPS extruded polystyrene foam board production line uses polystyrene and a foaming agent as raw materials, which are formed into an insulating board through high-temperature extrusion. Currently, the main foaming agent used in the industry is hydrochlorofluorocarbon (HCFC), which has a relatively high potential for ozone layer depletion. According to the Montreal Protocol, China has been gradually restricting the use of HCFCs. Shandong Tongjia Machinery Co., Ltd., based on market trends, has introduced advanced technology and tailor-made R&D to develop CO2 extruded board equipment that completely replaces HCFC foaming agents with CO2, truly achieving a fluorine-free foaming process and pioneering the use of CO2 foaming.

| Model TJ-XPS | 75P/150 | 75P/170 | 75P/200 | ||||

| Extruder | Ø75 twin | Ø150 | Ø75 double | Ø170 | Ø75 twin | Ø200 | |

| Product thickness | mm | 20-100 | 20-110 | 20-120 | |||

| Product Width (optional) | mm | 600/900/1220 | |||||

| Production capacity (approx.) | KG/h | 400-550 | 500-600 | 550-700 | |||

| Installed capacity (approx.) | KW | 300 | 350 | 400 | |||

| Overall dimensions (approx.) | m | 50 × 15× 4 | 55 × 15 × 4 | 70 × 15 × 4 | |||

| Machine weight (approx.) | T | 26 | 28 | 40 | |||

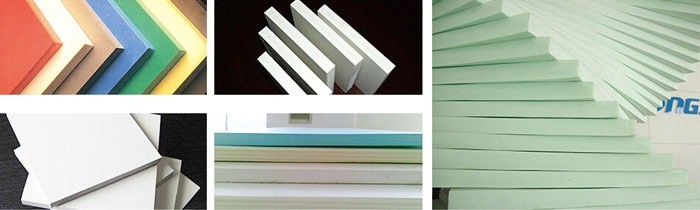

Equipment Display

Multi-component blending system

Fully automatic computer-controlled blending of various raw materials, using a loss-in-weight precise measurement method, strictly adhering to the set ratios for mixing, to produce high-quality products.

Laying the foundation for quality, the feeding system adopts vacuum feeding to ensure stable material delivery.

Cooling and constant temperature system

Precision ratio control cooling system, equipped with high-power chillers, to ensure good cooling performance and meet the stringent requirements of the cooling system in the production process.

Engraving requirements.

Extrusion system

The CO2 XPS extrusion system adopts a parallel twin-screw extruder with a modular screw design, which is combined for use according to the processing technology of the material. Specially designed

Connection method, the transmission device enhances the strength of the screw elements and the core shaft, achieving uniform dispersion and good mixing of the material.

supercriticalCO2 foaming agent injection system

supercriticalThe CO2 foaming agent injection system is a utility model patent product developed by our company, adopting a fully imported flow control system for precise control.

The instantaneous volume flow rate and mass flow rate of the foaming fluid, design a closed-loop control program to maintain the stability of the mass flow rate. Unique three-stage pressurized injection

System, maintaining a stable liquid phase state of CO2, ensuring the formation of a homogeneous system, and employing an automatic flow feedback control system to maintain the flow rate of the foaming agent.

stability

Conveying system

Molding system with bidirectional electrically adjustable device, proportional control low-resistance system material, double-sided setting

Fixed Length Cut

Online post-processing system, the cooled and shaped products, automatic fixed-length cutting and trimming, longitudinal and transverse edge forming, automatic stacking, multi-point monitoring, auto

Motion alarm, automatic packaging system.

◆ For waterproofing, insulation, and heat preservation of building walls and roofs in residential buildings, office buildings, and industrial plants

◆ Insulation panels for cold storage, providing cold retention and waterproofing

◆ For central air conditioning ventilation ducts, for insulation and thermal preservation

Materials for preventing frost heave in concrete water conveyance channels used in water conservancy projects (such as the South-to-North Water Diversion Project)

◆ For frost protection and thermal insulation in roadbed engineering for highways, railways, airports, squares, etc.

Whats App

Whats App

Plastmatch App

Scan the QR code

Plastmatch App

Scan the QR code 1000+ Daily Updated Global Business Leads,2M+ Global Company Database.Click to download the app.

Purchase request Download app