Yangtze River Pump Industry Company has developed a new type ofDBY Electric Diaphragm Pump, which uses the BLY series cycloidal pinwheel reducer for power transmission, replacing the traditional turbine worm reducer. At the same time, due to the significant breakthroughs in diaphragm materials in recent years, this series ofelectric diaphragm pumps can more widely replace somecentrifugal pumps,screw pumps,submersible pumps,mud pumps, andimpurity pumps, and is applied in industries such as petroleum, chemical, metallurgy, ceramics, etc.

DBY Electric Diaphragm Pump Features

1. Compact structure, small size, lightweight, easy to assemble and disassemble;

2. High transmission efficiency;

3. Smooth operation, low noise;

4. Long service life;

5. Can transport media without leakage;

6. Can withstand no-load operation;

7. No need for priming, self-priming capability;

8. Good through performance, can effortlessly pass large particles of impurities, mud, etc.;

9. Since the diaphragm separates the conveyed medium and the transmission mechanical components, the medium will not leak out. Moreover, the pump itself has no shaft seal, greatly extending its service life. Depending on the different media, diaphragms are available in neoprene, fluororubber, and nitrile rubber, meeting the requirements of different users.

Electric Diaphragm Pump Main Uses

1. Various highly toxic, flammable, and volatile liquids. 2. Various strong acids, strong bases, and highly corrosive liquids. 3. Can transport media at higher temperatures up to 150°C. 4. As a pressure feeding device for various filter presses. 5. Hot water recovery and circulation. 6. Unloading and loading of oil tankers, oil depots, and oil products. 7. Pumping pickles, jam, mashed potatoes, chocolate, etc. 8. Pumping paint, resin, pigments, and adhesives. 9. Various ceramic glaze, cement, grouting, and slurry. 10. Various rubber slurry, latex, organic solvents, and fillers. 11. Pumping out wastewater and residual oil from the holds of oil tankers and barges. 12. Pumping hops and yeast slurry, syrups, and sugar concentrates. 13. Pumping sewage and sediment from mines, tunnels, and sewers. 14. Transporting various special media.

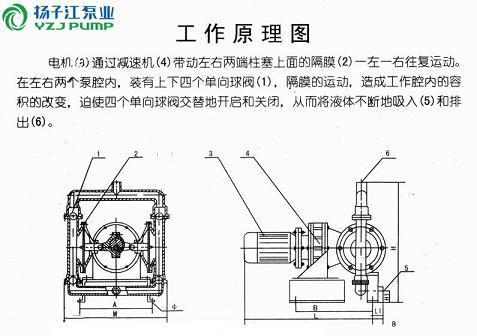

Structure Diagram of the Electric Diaphragm Pump: