| Model Significance: | ||

|

For example: IR50-32-200(A) IR-anti-corrosion thermal insulation pump 50- inlet diameter (mm) 32- outlet diameter (mm) 200- nominal diameter of the impeller (mm) A- impeller outer diameter after secondary cutting |

|

|

|||||||

|

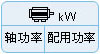

IR Type Anti-Corrosion Thermal Insulation Pump Performance Parameter Table

|

|||||||

|

|

|

|

|

|

|

|

|

IR50-32-125

|

12.5

|

20

|

2900

|

1.33

|

2.2

|

51

|

2.0

|

|

6.3

|

5

|

1450

|

0.19

|

0.55

|

45

|

2.0

|

|

|

IR50-32-160

|

12.5

|

32

|

2900

|

2.37

|

3

|

46

|

2.0

|

|

6.3

|

8

|

1450

|

0.34

|

0.55

|

40

|

2.0

|

|

|

IR50-32-200

|

12.5

|

50

|

2900

|

4.36

|

5.5

|

39

|

2.0

|

|

6.3

|

12.5

|

1450

|

0.65

|

1.1

|

33

|

2.0

|

|

|

IR50-32-250

|

12.5

|

80

|

2900

|

8.25

|

11

|

33

|

2.0

|

|

6.3

|

20

|

1450

|

1.27

|

2.2

|

27

|

2.0

|

|

|

IR65-50-125

|

25

|

20

|

2900

|

2.2

|

3

|

62

|

2.0

|

|

12.5

|

5

|

1450

|

0.31

|

0.55

|

55

|

2.0

|

|

|

IR65-50-160

|

25

|

32

|

2900

|

3.82

|

5.5

|

57

|

2.0

|

|

12.5

|

8

|

1450

|

0.53

|

0.75

|

51

|

2.0

|

|

|

IR65-40-200

|

25 |

50

|

2900

|

6.55

|

11

|

52

|

2.0

|

|

12.5

|

12.5

|

1450

|

0.93

|

1.5

|

46

|

2.0

|

|

|

IR65-40-250

|

25

|

80

|

2900

|

11.84

|

15

|

46

|

2.0

|

|

12.5

|

20

|

1450

|

1.75

|

3

|

39

|

2.0

|

|

|

IR65-40-315

|

25

|

125

|

2900

|

21.8

|

30

|

39

|

2.0

|

|

12.5

|

32

|

1450

|

3.3

|

5.5

|

33

|

2.0

|

|

|

IR80-65-125

|

50

|

20

|

2900

|

3.95

|

5.5

|

69

|

3.0

|

|

25

|

5

|

1450

|

0.53

|

0.75

|

64

|

2.5

|

|

|

IR80-65-160

|

50

|

32

|

2900

|

6.51

|

11

|

67

|

2.3

|

|

25

|

8

|

1450

|

0.88

|

1.5

|

62

|

2.3

|

|

|

IR80-50-200

|

50

|

50

|

2900

|

10.81

|

15

|

63

|

2.5

|

|

25

|

12.5

|

1450

|

1.49

|

2.2

|

57

|

2.0

|

|

|

IR80-50-250

|

50

|

80

|

2900

|

20.57

|

30

|

53

|

2.5

|

|

25

|

20

|

1450

|

2.72

|

4

|

50

|

2.0

|

|

|

IR80-50-315

|

50

|

125

|

2900

|

34.1

|

45

|

50

|

2.5

|

|

25

|

32

|

1450

|

4.54

|

7.5

|

48

|

2.5

|

|

|

IR100-80-125

|

100

|

20

|

2900

|

7.47

|

11

|

73

|

4.2

|

|

50

|

5

|

1450

|

0.99

|

1.5

|

70

|

4.0

|

|