Modular screw elements, computer-precisely designed screw configurations, increased length-to-diameter ratio, and adjustable structures according to process requirements for optimized configuration. The screw elements and core shaft are connected by involute splines, achieving higher torque and greater screw volume. The material of the screw elements is high-quality alloy steel W6Mo5CrV2, and the core shaft material is 40CrNiMoA. The inner side of the barrel is equipped with a dual-alloy liner, suitable for various operations. The vacuum exhaust barrel allows for the full evaporation of moisture in the material, reducing the moisture content of the granules.

| Machine Model | TJ-ZL75P | TJ-ZL95P | |

| Screw diameter | mm | Ø75×2 | Ø95×2 |

| Number of screws | (piece) | 2 | 2 |

| Rotational speed | r/min | 1-500 | 1-500 |

| Main motor power | KW | 132/160 | 280 |

| Cooling method | air cooling | ||

| aspect ratio | 48:1 / 52:1 | 48:1 / 52:1 | |

| Heating power (approx.) | KW | 80 | 150 |

| Extrusion output | kg/h | 300-600 | 500-800 |

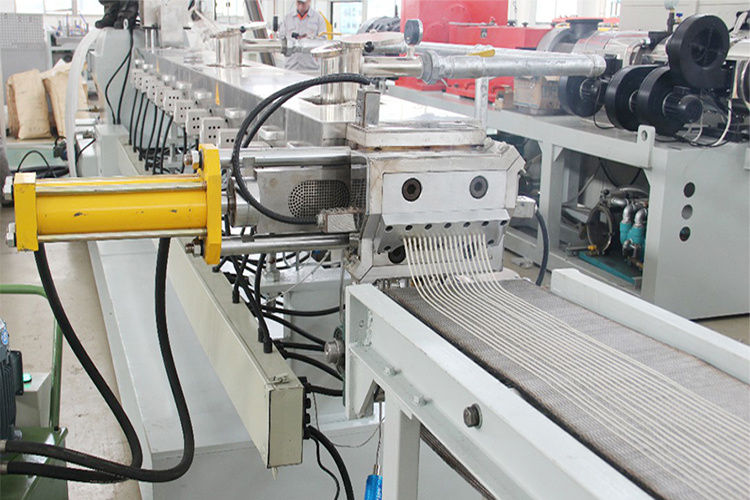

Equipment Display

Whats App

Whats App

Plastmatch App

Scan the QR code

Plastmatch App

Scan the QR code 1000+ Daily Updated Global Business Leads,2M+ Global Company Database.Click to download the app.

Purchase request Download app