Researchers Develop Novel Aluminum Alloy to Achieve High Ductility

Most aluminum alloys produced by additive manufacturing (AM) technologies exhibit very limited ductility in the final products, which may lead to the necessity of using more expensive and heavier alternative materials in applications such as automotive and aerospace components. The insufficient ductility of AM alloys may stem from specific processing defects or microstructural characteristics. Researchers have conducted extensive studies to optimize these processing defects, but the influence of microstructure still restricts the ductility of high-strength aluminum alloys after forming.

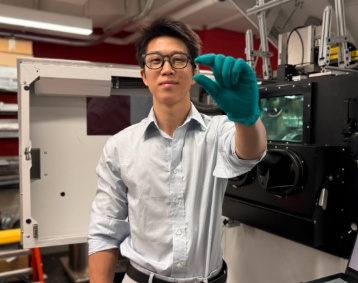

According to foreign media reports, researchers from the Department of Materials Science and Engineering at Carnegie Mellon University have developed a new type of aluminum alloy (Al-Ni-Er-Zr). Through optimized compositional design, the ductility of the final product has been increased from 0.9% to 19%, while minimizing the negative impact on the alloy’s strength.

In a recent paper published in npj Advanced Manufacturing, researchers shared integrated computational materials engineering (ICME) simulation results based on CALPHAD (Calculation of Phase Diagrams) and their validation.

Image source: Carnegie Mellon University

In this study, the research team systematically investigated the embrittlement stages in existing alloys that have low ductility but high strength, in order to understand the causes of their rapid fracture.

Assistant Professor Mohadeseh Taheri-Mousavi stated, "Once we have identified the root cause of the fracture, we can perform simulations to understand how to optimize the elements in a way that maximizes strength and ductility."

For manufacturing techniques that make subsequent heat treatment of components difficult (such as welding), high finished product ductility is very important. These processes are crucial for structural integrity in applications such as automobiles and aircraft.

Taheri-Mousavi said, "With improvements in ductility, strength, and temperature resistance, aluminum alloys are expected to replace heavier and more expensive titanium alloys, nickel alloys, and steel."

The ductility of the final product (excluding any subsequent processing) is very important for large-scale printing in additive manufacturing, as materials with low ductility cannot withstand the residual stresses generated during the printing process. Therefore, this new formulation is expected to be applied to large components in automotive and aerospace parts.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

Key Players: The 10 Most Critical Publicly Listed Companies in Solid-State Battery Raw Materials

-

Vioneo Abandons €1.5 Billion Antwerp Project, First Commercial Green Polyolefin Plant Relocates to China

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Clariant's CATOFIN™ Catalyst and CLARITY™ Platform Drive Dual-Engine Performance

-

List Released! Mexico Announces 50% Tariff On 1,371 China Product Categories