Chinese Takeout Bags Quietly Conquer Africa! The First Packaging to Capture the African Market Is Actually Them?

You would never guess that various inconspicuous delivery bags in China, whether new or used, are considered rare treasures in Africa.

From the top domestic and international delivery brands Manling Porridge Shop and Bawang Tea Princess, to the well-established supermarket brands Red Bull, Lulu, and Brain Platinum.

Where there are Africans, there are their figures.

"A bag per household" is no longer surprising; even more so, some carry bags in both hands, filling them up completely.

The Chinese characters from the distant East merge with the colorful attire to become a bright and beautiful sight.

Chinese takeout bags dominate Africa

What’s more surprising is that African tote bags also come in different grades. It is said that the most popular ones are those with bright yellow and red festive colors, and their prices are relatively higher—a single bag can sell for more than one RMB.

How did these handbags get from China to Africa?

Moreover, it quickly transformed into a fashion item, rapidly sweeping the streets.

Although takeout bags are small, "where there is business, there is a world of competition."

According to Statista data, the global packaging bag market was valued at 185 billion USD in 2023, with the food and retail industries being the main drivers of demand, accounting for 35% and 28% respectively. The market size is expected to reach 240 billion USD by 2028, making it a truly "hundred-billion-dollar business."

When simply searching for the keyword "takeout tote bag" on a shopping platform, numerous sellers appear with price tags ranging from 0.1 to 0.3 yuan, and many indicate "compliant with international standards."

There are companies specializing in the international transportation of handbags, and after being shipped to Africa, each can yield a profit of about 1 yuan. The integration of production, transportation, and landing can be seamlessly connected without leaving the platform, making it a highly profitable business.

Chinese shopping platforms enable international shipping for handbags.

The delivery bags have been sent to Africa, but what if no one takes them?

Some merchants have targeted Alibaba International Station, which offers semi-managed services responsible for point-to-point contact with African businesses. This way, having a source of goods means no worries about sales. Once on the ground, orders are immediately connected with buyers, who then wholesale the tote bags to African street vendors, forming a widespread sales network of tote bags.

Local convenience stores are all selling takeout tote bags.

So, do Africans not have their own handbags?

Yes, and there are quite a variety of styles. African straw bags and African wax print cloth bags are common souvenirs that Chinese tourists often bring back.

However, since many of them are handmade, the prices have naturally risen accordingly, with items costing over a thousand yuan not uncommon. The price level has been described as "catching up with Europe."

In addition, Carrefour Africa also launched "internet celebrity items" - shopping bags with a grassland theme, categorized by size into Rhino (small), Lion (medium), and Elephant (large). However, for people living in remote areas with average economic conditions, specifically purchasing woven bags is still considered relatively luxurious.

Shopping bags sold in Carrefour supermarkets in Kenya

The "Chinese takeout bag trend" originates from a pain point of Africans:

In Africa, takeaway orders usually come with plastic containers, while most hotels do not provide plastic bags.

Therefore, everyone can only turn their attention to the Chinese tote bags sold at street stalls, which is actually a win-win solution for both parties.

Behind this, there are plastic ban regulations being promoted in many African countries.

As early as 2017, Kenya issued what was claimed to be the world's strictest ban on plastic.

According to regulations, the use, manufacture, and import of all plastic bags for commercial and household purposes are strictly prohibited in the country. Any violation will result in 1 to 4 years of imprisonment or a fine of $19,000 to $38,000.

It should be noted that a fine of over ten thousand is almost equivalent to the annual income of a family of three in that country.

Kenya is not an isolated case; previously, 15 other countries have introduced bans or restrictions on plastic to completely eliminate white pollution.

Taking Rwanda as an example, in 2004, Rwanda banned the use of plastic bags in stores and encouraged manufacturers to recycle plastic bags through tax reduction measures.

In 2008, the country completely banned the use of plastic bags, and its capital Kigali has since been named "the cleanest city in Africa" by the United Nations Human Settlements Programme.

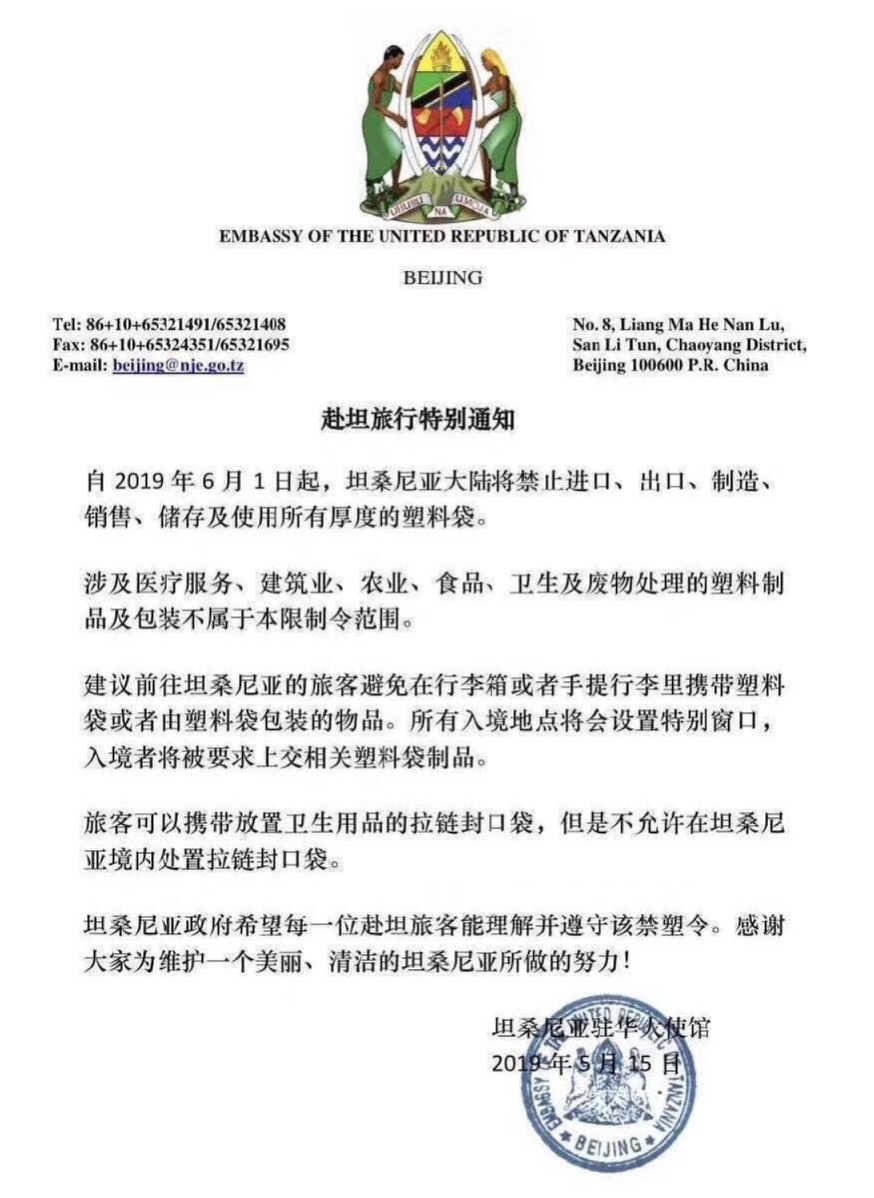

Not only are Africans themselves prohibited from using plastic bags, but tourists wishing to visit Africa must also leave plastic bags behind.

After all, the Tanzanian government clearly states: "From June 1, 2019, all tourists traveling to the country are prohibited from bringing plastic bags into the country."

Rather persuade others to leave than give up on "decluttering."

The Embassy of Tanzania in China issues a notice to tourists.

In 2023, the United Nations Environment Programme also released a report listing more than 80 countries that have implemented varying degrees of plastic bans or restrictions, 28 of which are located in Africa.

Some people joke, "In Africa, even if you have money, you can't buy plastic bags." In many ways, Africa lags behind others, but when it comes to banning plastics, it has already surpassed developed countries.

Why has Africa specifically taken a strong stance against plastic, and done so swiftly, accurately, and decisively?

In recent years, the plastic dilemma faced by Africa has worsened dramatically, possibly an unforeseen consequence of the traditional development path.

Africa is the fastest-growing continent in terms of population, and the United Nations estimates that it will add 1.3 billion people by 2050.

Meanwhile, urbanization is rapidly advancing in coastal areas.

This should have brought about a huge consumer market; however, the reality is that the development of waste management capacity has lagged far behind the explosive growth of population, urbanization, and consumption.

As a result, a large number of unprocessable single-use plastic bags eventually end up in the ocean.

The report from the World Economic Forum is alarming: every year, $80 billion worth of plastic packaging ends up in the ocean. At this rate, by 2050, there will be more plastic in the sea than fish.

This is especially devastating for Africa, where fisheries sustain more than 12 million people and serve as the primary source of protein for many countries.

Microplastics return to the human body through the food chain, threatening health and food safety.

Plastic bags blocking the drainage system have directly caused tragedies in the past, such as the 2015 flood disaster in Accra, Ghana, which resulted in at least 150 deaths.

The landfill accident (the 2017 Addis Ababa landslide that resulted in 110 deaths) is even more shocking.

The plastic mountains on the city's outskirts and the white pollution flying chaotically with the wind not only directly detract from the city's appearance but also contribute to the spread of mosquito-borne diseases.

At this time, many African governments have taken strong measures: imposing heavy penalties and banning plastics.

Is there any effect? Yes.

Kigali, the capital of Rwanda, has become the cleanest city in Africa.

The notorious "flying toilets" (plastic bags filled with excrement thrown indiscriminately) in Nairobi have basically disappeared.

However, the heart-wrenching question arises: does this strictest ban really address the root of the problem? And what is the cost?

Kenya's ban directly impacted 176 local plastic factories and tens of thousands of jobs, with cheap packaging bags gone and costs skyrocketing.

There is also a lot of controversy among the public, with some people feeling that simply using a plastic bag might be regarded as "drug trafficking," and that they could face public humiliation.

Why do African countries still choose this path?

Perhaps it is a shortcut to a helpless reality: it can quickly clean the streets, strongly change consumption habits, and enhance environmental awareness.

Moreover, in Africa, plastic recycling is extremely difficult. International companies consider the market too small and unprofitable, and are unwilling to invest in facilities. The cost of plastic recycling itself is high, and the market for recycled materials is unstable, with quality often inferior to that of new materials.

The Chaos of Africa's "Plastic Waste Mountains"

Therefore, Africa's strict anti-plastic measures seem more like a harsh remedy forced upon them when their infrastructure is severely lacking and pollution has reached a critical level.

It can stop bleeding quickly, but it is difficult to eliminate the root cause of the disease and is accompanied by severe side effects.

Chinese takeout bags are mostly made of non-woven fabric, which can provide multiple functions such as insulation, leak prevention, spill resistance, and environmental protection. They remain intact even after long-distance transportation, demonstrating very high quality.

To ensure insulation and freshness, takeout bags have widely adopted multi-layer three-dimensional thermal insulation structures and vacuum materials, and upgraded leak-proof performance with a "double-layer locking structure and anti-spill groove," aiming to provide a fully enhanced user experience.

The attractiveness and fun of takeaway packaging are regarded as part of a brand's assets. Appealing takeaway packaging has become a new direction for businesses' "involution." Many businesses are putting effort into "how to use patterns and colors to create a visual impact for consumers," aiming for both a sense of identity and the desire for social sharing.

HEYTEA’s black insulated bag that is “spacious, portable, and reusable,” Tai Er’s black-and-white comic-style design, and BaWangChaJi’s new Chinese-style tote bag have all left a deep impression on consumers.

A key factor driving the export of takeaway bags is that they not only have superior performance and diverse designs, but their prices are also continuously decreasing.

In the context of the "subsidy war" in China, takeaway packaging has become a competitive barrier for cost control among businesses.

As the third largest variable cost after ingredients and platform fees, every 1% reduction in packaging cost rate has a significant impact on net profit.

Chinese Fancy Non-woven Fabric Tote Bag

High-quality, creatively designed Chinese takeout bags that can be preserved for a long time naturally have a competitive advantage in going global.

Especially when compared with locally made African takeaway bags, it is only natural that ordinary people prefer the high-quality and affordable Chinese-style takeaway bags.

Everyone knows how difficult it is to upgrade the manufacturing industry, especially when facing “veteran players” like Japan and the United States.

China's non-woven fabric industry started late, but this has in no way hindered its spectacular transformation from "buying globally" to "selling globally" in just a few years.

Last year, China’s nonwoven fabric production reached approximately 8.561 million tons. Compared to 2014, the average annual compound growth rate was as high as 7%, nearly doubling over the past decade and making China a heavyweight player in the global market.

Non-woven bags, which once relied on imports, now see Chinese shelves piled high with export orders. Behind this transformation, local forces have forcefully carved out a new path with their own three-pronged approach.

China's non-woven fabric industry had already developed into a mature, large-scale industry by 2017, following the implementation of "plastic bans" in many African countries.

The first is the "cluster effect" of industrial groups working together to outcompete others.

The value of the phrase "For global non-woven fabrics, look to China; for Chinese non-woven fabrics, look to Xiantao" speaks for itself.

Xiāntáo, a county-level city, has gathered over 2,700 enterprises, 195 large-scale enterprises, and nearly 100,000 employees, with an annual production exceeding 1 million tons, becoming a non-woven fabric city.

From raw materials and equipment to product processing, auxiliary materials support, and logistics transportation, the entire chain is resolved locally.

Xiantao non-woven fabric products participate in international exhibitions.

In addition, Zhejiang, Shandong, Jiangsu, Fujian, and Guangdong—the five major coastal provinces—form the absolute core of nonwoven fabric production in China. With the strong rise of central Hubei in the fields of spunbond and all-cotton spunlace, these regions have together become an unshakable and solid foundation for China’s nonwoven fabric industry.

Such tightly knit industrial clusters bring not only cost advantages, but also lightning-fast responsiveness and unparalleled collaborative innovation.

An order comes in, and the entire chain instantly springs into action. This is the power of the "cluster model," turning "scattered sparks" into a raging fire.

The second is a complete industry chain that can cover all aspects.

In its early days, China was constrained by other countries, with raw materials and equipment significantly lagging behind. What to weave and how to weave all depended on imports from abroad.

But times have changed; electrospinning equipment has been developed, and production lines for biodegradable materials such as bio-based PLA and PBS are now available. You can make whatever you want by yourself.

Not only food delivery bags, but also face masks, wet wipes, flame-retardant layers for automotive battery packs, aerospace materials, and high-end medical beauty dressings—China can handle it all in one go, with exports covering more than 150 countries.

Whatever the market wants, I can quickly create it faster and more comprehensively than you.

Not only is the range of categories complete, but China’s nonwoven fabric industry is also making greater strides in high-end and cutting-edge fields. Technologies such as flash-spinning and meltblown pulp, which once seemed distant to us, have now become valuable assets in pioneering new blue oceans in hygiene and food packaging.

Medical protective clothing made by flash spinning technology

Why has China been able to achieve a successful turnaround?

The core lies in China's vast and demanding market.

The consumption and industrial upgrades of 1.4 billion people have led to ever-changing demands for the performance, functionality, and environmental friendliness of non-woven fabrics.

Local manufacturers are being forced to evolve by demand; if they don't move fast, they die; if they aren't innovative, they perish!

In order to survive and to consume this big cake, they must crazily invest in research and development, relentlessly tackle technology, and optimize the chain, ultimately forging the strength to directly compete with the Japanese and American giants.

Of course, it is undeniable that there are some elements of chance involved.

The massive demand for masks during the 2020 pandemic unexpectedly became a strong catalyst for the technological leap in nonwoven fabrics; in 2024, with the global economic recovery, demand for nonwoven fabrics rebounded and generally grew across major economies; a series of domestic policies aimed at promoting qualitative and quantitative economic growth have precisely targeted support, greatly boosting the explosion of nonwoven fabrics in technological innovation, fixed asset investment, and application promotion.

However, no matter what, non-woven fabric is no longer just "fabric" in the simple sense.

From small takeaway bags traveling as far as Africa to large-scale applications in strategic fields that concern national economy and people's livelihood such as military, aviation, transportation, and healthcare, non-woven fabrics are playing an increasingly crucial role...

China has never relied on luck, but rather on its solid industrial ecosystem advantages and cutting-edge technologies.

Source: Zhengjieju

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

Key Players: The 10 Most Critical Publicly Listed Companies in Solid-State Battery Raw Materials

-

Vioneo Abandons €1.5 Billion Antwerp Project, First Commercial Green Polyolefin Plant Relocates to China

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Clariant's CATOFIN™ Catalyst and CLARITY™ Platform Drive Dual-Engine Performance

-

List Released! Mexico Announces 50% Tariff On 1,371 China Product Categories