Biobased Radiative Cooling Fibers Developed by Academician Zhumeifang's Team: Over 5°C Perceived Cooling, Breathable, Moisture-Wicking

With the growing global demand for sustainable cooling technologies, passive daytime radiative cooling technology has attracted significant attention for its ability to directly radiate heat to space through the atmospheric transparency window. However, most existing radiative cooling fabrics rely on petroleum-based synthetic materials and complex coating processes, which are not environmentally friendly and severely impact the breathability and wearing comfort of textiles, limiting their widespread application in the wearable field.

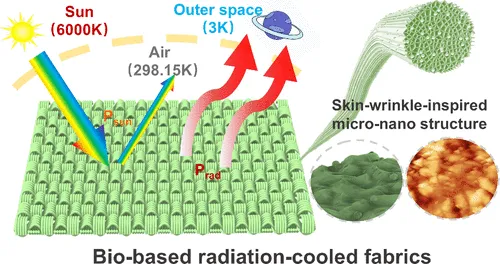

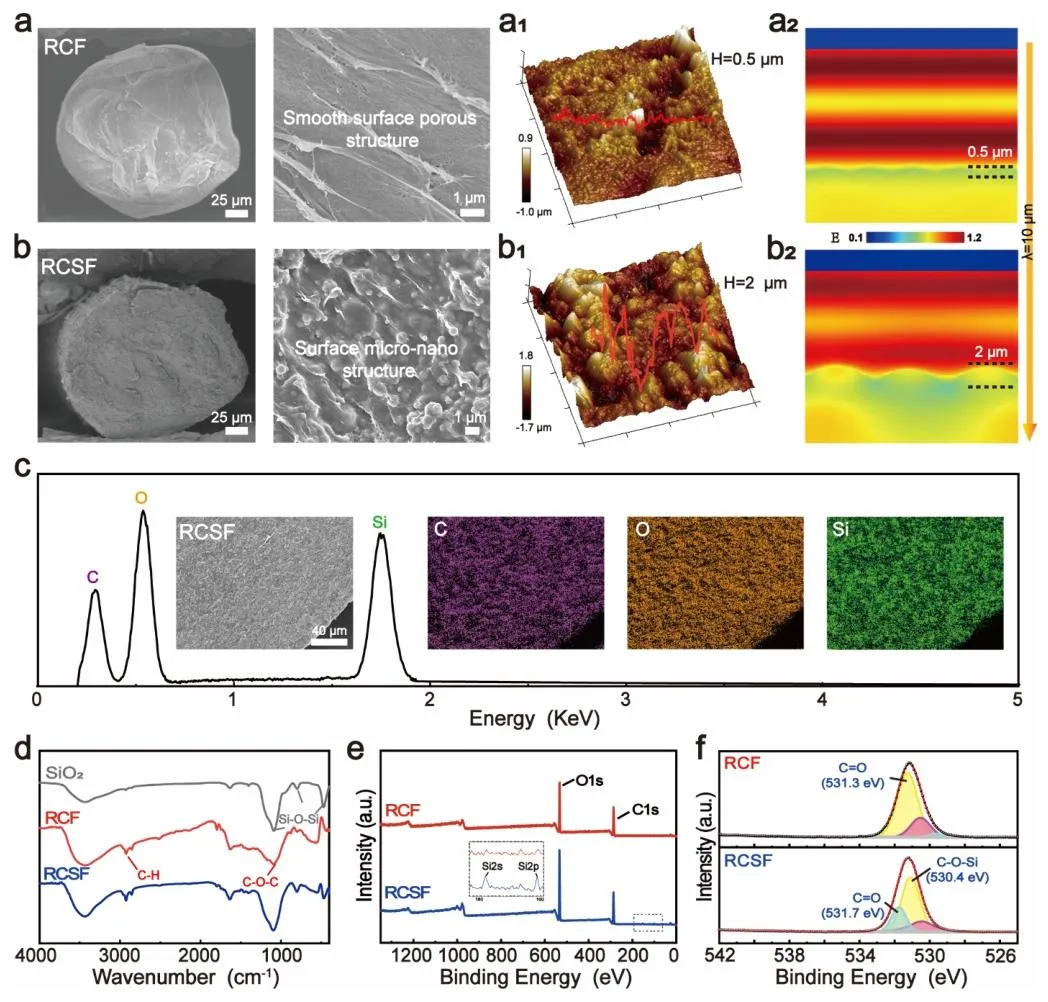

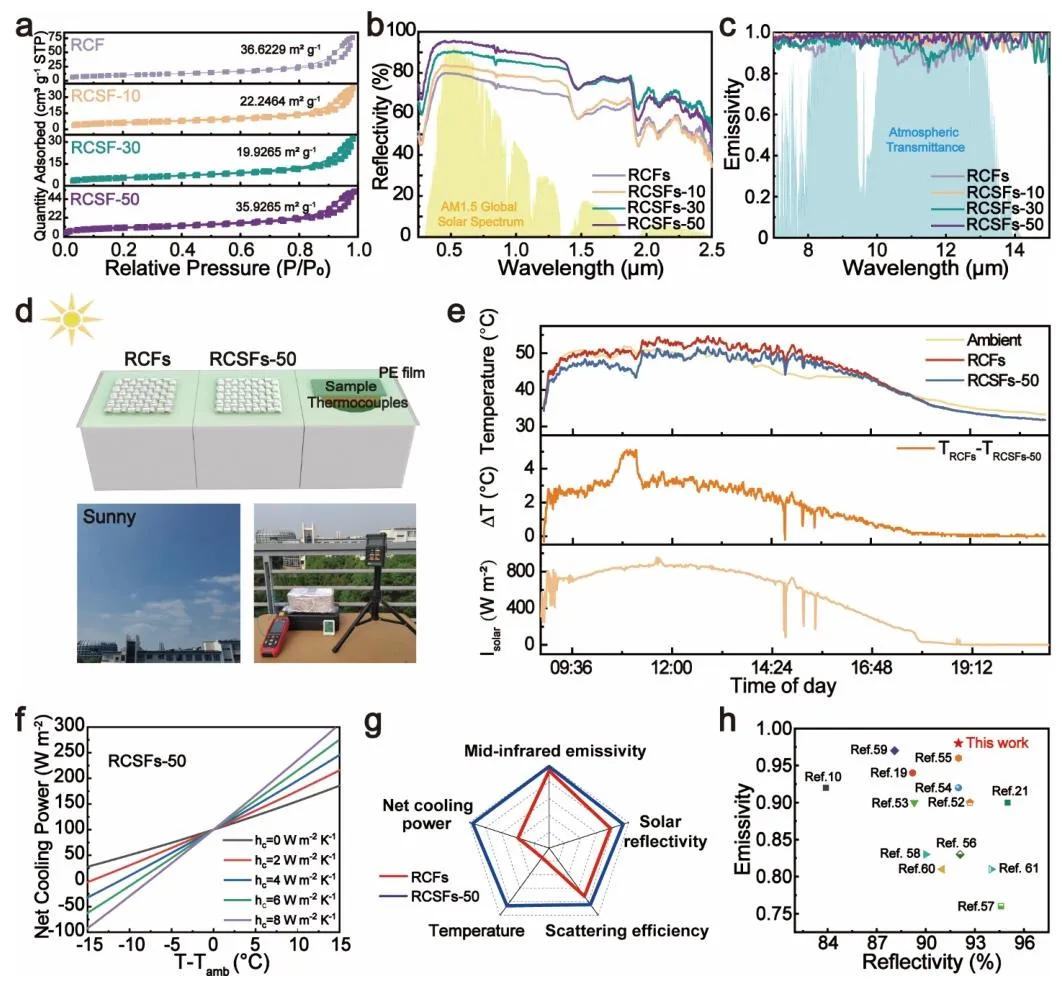

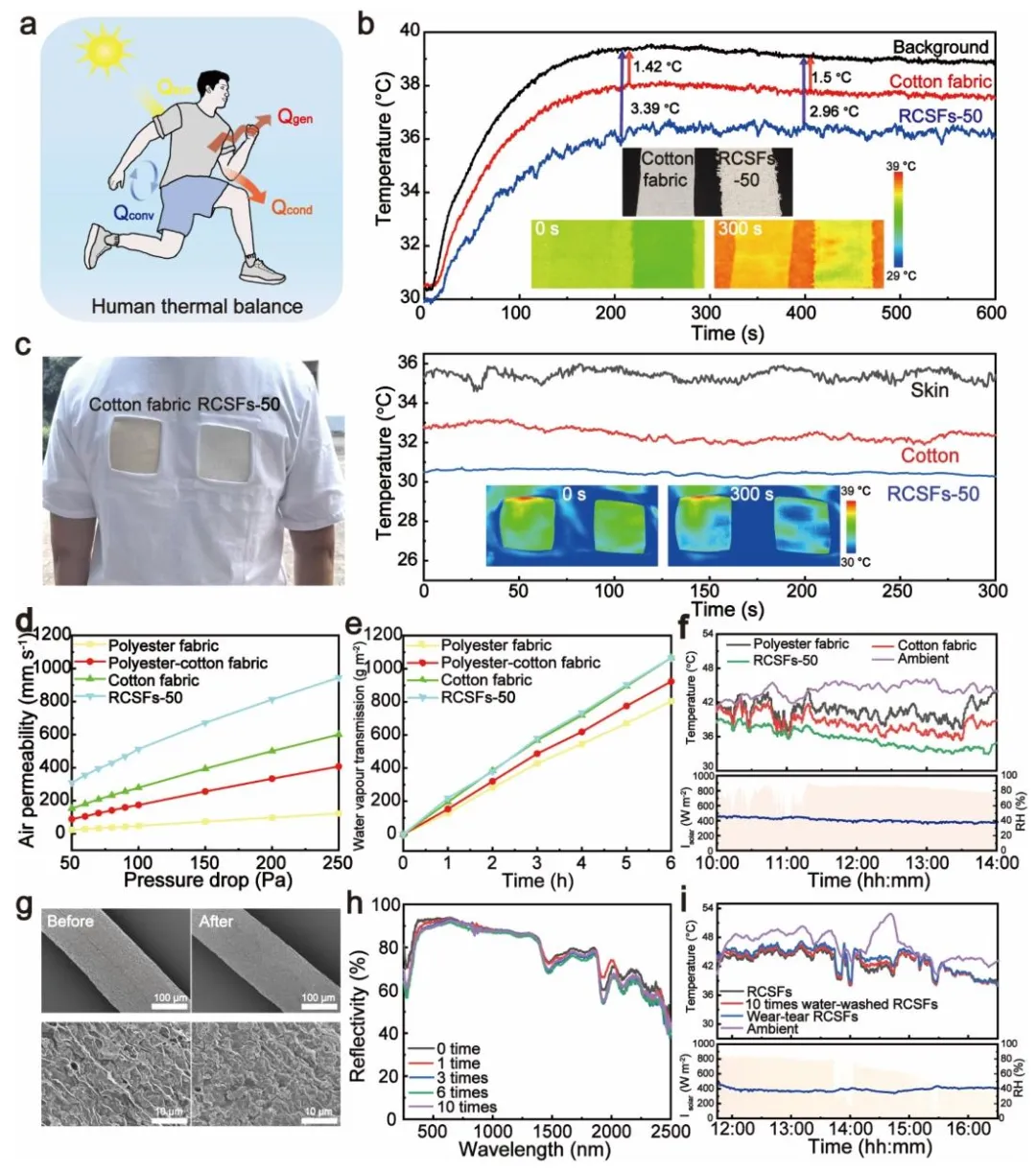

Based on this, the team led by Associate Researcher Kong Weiqing and Professor Zhu Meifang from Donghua University proposed a bio-inspired, coating-free green strategy and successfully prepared regenerated cellulose/SiO₂ nanoparticle composite fibers through wet spinning technology. These fibers mimic the micro-nano wrinkle structures on human skin surfaces, achieving a solar reflectance of up to 93.7% and an infrared emissivity of 0.98, enabling efficient heat dissipation without any external coating. Under a solar irradiation of 800 W/m², this material can achieve a net cooling power of 100.1 W/m², cooling down by more than 5°C compared to ordinary cellulose fabrics in summer conditions, while possessing excellent breathability and moisture-wicking properties, providing a new solution for sustainable personal thermal management.

On September 25, 2025, the related paper was published in ACS Nano under the title "Eco-Friendly Skin-Wrinkle-Inspired Micro-Nano Structured Cellulose Composite Fibers for Highly Efficient Daytime Radiative Cooling."

The key aspect of this research lies in the one-step manufacturing process that eliminates the need for toxic coatings and energy-intensive post-treatment procedures, providing a cost-effective alternative to traditional coated fabrics. By combining renewable cellulose with the design of biomimetic skin wrinkle structures, an eco-efficient radiative cooling material paradigm is pioneered, balancing optical performance, wearing comfort, and large-scale manufacturing.

Image and text description

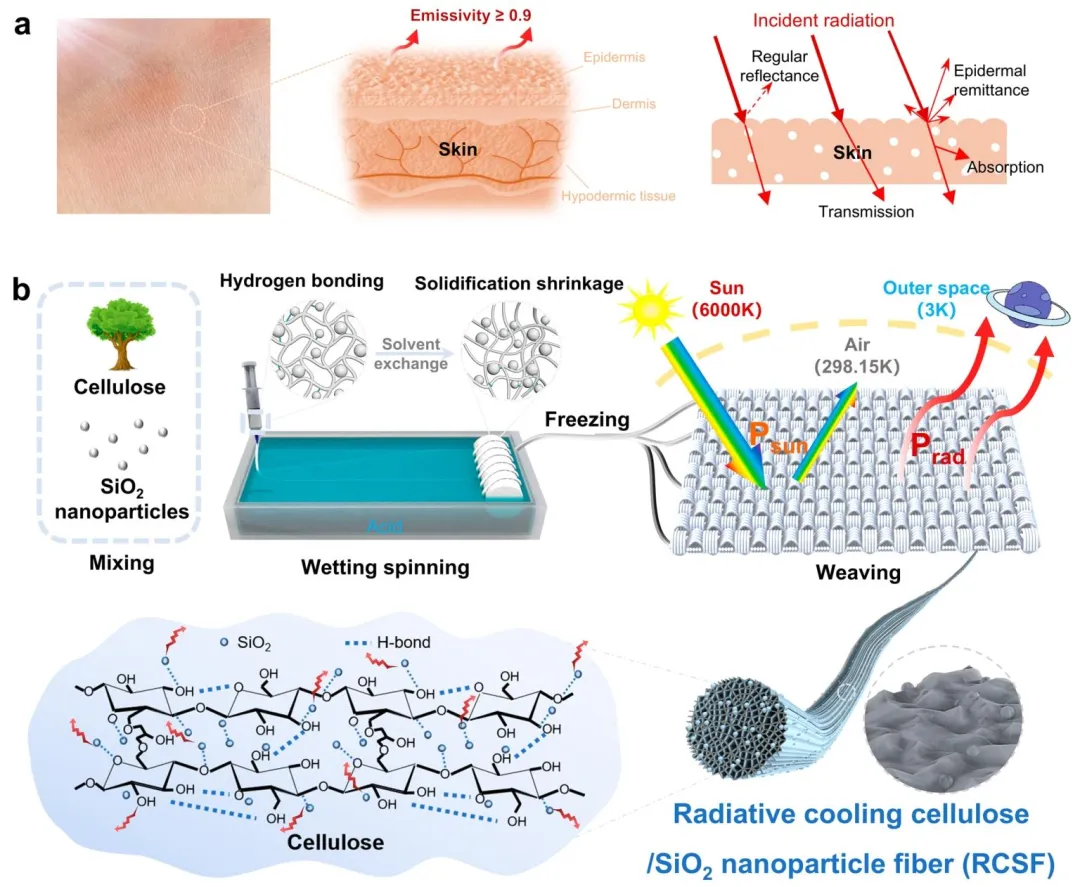

Inspired by the multilayer structure of human skin and its thermal regulation mechanism, micro-nano structured fibers resembling epidermal wrinkles have been designed. The biomimetic design concept and preparation process involve uniformly dispersing SiO₂ nanoparticles in a cellulose solution. During the wet spinning process, solvent exchange induces phase separation, resulting in the spontaneous formation of surface protrusions approximately 2 microns in height, simulating the light scattering and infrared radiation characteristics of the skin surface, achieving an integrated structure-function formation.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track