Breakthrough in application: Recycled PMMA Sunshade Boards Installed on Vehicles, Reviewing Mitsubishi Chemical's Progress in Recycled Plastics

Specialized VisionObserved on September 15,Mitsubishi Chemical Corporation and Honda Motor Co., Ltd. jointly announced thatThe jointly developed acrylic resin recycling material has been officially applied to new lightweight electric passenger vehicles.The sun visor of the "N-ONE e:" car door。

This innovation marks the first commercial application of recycled acrylic resin materials in the field of car door sunshades in the global automotive supplies industry, ushering in a new era of green manufacturing for automotive components.The specific product applied this time is produced by Mitsubishi Chemical through chemical recycling technology.Recycled PMMA material.The material has been rigorously tested and verified, with its transparency, weather resistance, and mechanical properties all meeting the standards of virgin materials, and the carbon dioxide emissions during the production process have been reduced.More than 70%.

Source: Honda

During the project implementation, Mitsubishi Chemical collaborated with the Hokkaido Automotive Treatment Cooperative to establish a dedicated recycling channel, ensuring that the acrylic resin components recovered from end-of-life vehicles are free from foreign materials. Through microwave pyrolysis technology, they achieved efficient regeneration. This breakthrough not only addresses the industry's pain points of poor quality stability and difficulty in reuse associated with traditional recycling technologies but also achieves...The full-chain closed loop of "recycling-regeneration-application".

According to Specialty Plastics Vision, The N-One e: is an electric kei car featuring a boxy body, high roof design, and a robot-like front face, paired with small wheels that give it a cute yet slightly clumsy appearance. Unlike the version showcased at Goodwood, the mass-produced Japanese version of the N-One e: does not come with wheel arches to ensure compliance with kei car regulations, which cover various aspects from external dimensions to power output.

Technological Breakthrough: The Leap from Laboratory to Industrialization

Acrylic resinPMMA, known as the "transparent champion" among engineering plastics, is widely used in areas such as automotive taillights, dashboards, and window trims due to its excellent optical properties, weather resistance, and processing performance. However, traditional mechanical recycling technology faces two core challenges: firstly, waste PMMA is prone to thermal oxidative degradation during the recycling process, resulting in yellowing and reduced transparency of the recycled material; secondly, waste PMMA from different sources has significant differences in additives, making it difficult to achieve homogenized recycling through simple sorting.

Mitsubishi Chemical successfully overcame the above bottleneck through technological innovation.,Since 2021, the company has engaged in joint efforts with Microwave Chemical Co., Ltd. to develop microwave-induced PMMA chemical recycling technology. This technology precisely controls microwave frequency and temperature field distribution. Selective cleavage of PMMA molecular chains for efficient depolymerization into MMA monomers.The depolymerization efficiency of the process has been verified through experiments.The light transmittance of recycled PMMA can reach up to 92%, which is almost equivalent to that of virgin materials. More importantly, this technology overcomes the limitations of traditional chemical recycling that requires high temperature and high pressure, allowing the reaction to occur under normal pressure, significantly reducing energy consumption and equipment costs.

Source: Mitsubishi Chemical

In the specific application of the N-ONE e: car door sun visor, Mitsubishi Chemical Innovation has adopted a "horizontal recycling" system. By collaborating with Honda and the Hokkaido Automobile Processing Cooperative, they have established a comprehensive quality control standard for processes ranging from the dismantling of end-of-life vehicles, component sorting, cleaning and crushing, to regenerative granulation. Particularly in the foreign matter control phase, an AI visual inspection system has been introduced to automatically identify and remove non-acrylic impurities such as metal and rubber, ensuring that the purity of the recycled material exceeds 99.5%. The final recycled PMMA granules, after injection molding, have their mechanical properties and thermal stability rigorously tested by Honda, fully meeting the strength and weather resistance requirements for car door sun visors.

Mitsubishi Chemical collaborates with seven major companies.Building a full lifecycle closed loop for automotive plastics

Specialized VisionMitsubishi Chemical's involvement in the field of recycled plastics extends beyond the recovery of a single material.In February 2025, the company, along with seven multinational chemical enterprises including BASF and Covestro, established the "Global Impact Coalition (GIC)" with a focus on developing the supply chain for recycling plastics from end-of-life vehicles.The alliance sorts through.Ten types of polymers (including PMMA, PC, ABS, etc.) are being evaluated for recycling feasibility, actively exploring large-scale closed-loop solutions. Specifically, alliance members share dismantling data and regenerative technology standards, establishing a "material passport" traceability system from scrapped vehicles to new components. This ensures the traceability and quality consistency of each batch of recycled plastic, providing comprehensive assurance for the circular utilization of automotive plastics.

At the specific project level, Mitsubishi Chemical has been very active. ENEOS Group collaborates to establish a chemical recycling facility.The conversion of waste plastics into oil refining raw materials has been achieved."Turn waste into treasure"; In collaboration with REFINVERSE Group, the "Pla-relay Project" closed-loop recycling pilot is being carried out. This project involves multiple parties including the local government of Ibaraki Prefecture, waste material traders, and food packaging companies. By collecting used plastic bottle caps from elementary schools, the project goes through chemical recycling, resin production, molding processing, and final sales to form a complete recycling chain. It has become Japan's first closed-loop recycling case involving six parties, providing a "Japanese model" for global plastic waste recycling.

More noteworthy is that Mitsubishi Chemical has also introduced blockchain technology to achieve full-process traceability.Company andChaintope collaborates to develop a traceability system based on Tapyrus.The source, classification, and processing of waste plastics are stored on the blockchain, forming tamper-proof digital certificates. The system has been approved by the EU Digital Product Passport.DPP certification can meet the regulatory requirements in fields such as automotive parts and home appliances, providing global customers with transparent and trustworthy green supply chain solutions, further enhancing the market competitiveness of recycled plastics.

Mitsubishi Chemical Ibaraki Plant, image source: Mitsubishi Chemical

Mitsubishi Chemical currently plans to fully operate at the Ibaraki plant.The HydroPRS facility is being explored for expansion to handle Japan's 9 million tons of plastic waste annually on a larger scale. This trend indicates that recycled plastics will not only become the "green new engine" of the automotive industry but will also accelerate the global manufacturing industry's transition to a circular economy model, ushering in a new era of sustainable development.

Lessons Learned: The Japanese Model for China Inspiration

Japan's success in the field of recycled plastics provides a model for China to achieveThe "dual carbon" targets provide important reference. Firstly, Japan has revised the Act on the Promotion of Effective Utilization of Resources, mandating manufacturers to set targets for the use of recycled plastics and report progress regularly, with accompanying penalty mechanisms to ensure policy implementation. For example, Toyota Motor Corporation has committed to achieving a 30% share of recycled plastics in new cars by 2030 and is promoting technological innovation through investments in the recycling industry chain and the development of bio-based materials.

In contrast with China's current situation, despite...In 2021, the "Implementation Plan for the Pilot Program of Extended Producer Responsibility for Automotive Products" was released, requiring a 95% recycling rate for end-of-life vehicles by 2023. However, the actual dismantling rate remains significantly lower than that of developed countries. Currently, domestic end-of-life vehicle dismantling enterprises primarily recycle tires and scrap steel, while the technology for high-purity separate recycling of waste plastics is still underdeveloped. Additionally, the industry faces issues such as complex management and insufficient digital traceability.

Source: Mitsubishi Chemical

FutureChina needs to make efforts in three areas: first, improve the certification system for recycled plastic use and promote the development of bio-based materials, such as the plant-based materials being developed by Mitsubishi Chemical.Firstly, MMA monomer technology; secondly, building a full industry chain cooperation model, encouraging raw material companies, component suppliers, vehicle manufacturers, and recycling companies to establish joint laboratories to enhance dismantling technology and material traceability capabilities; thirdly, strengthening policy enforcement by incorporating the proportion of recycled plastic usage into automotive companies' carbon credit assessments, along with supporting financial subsidies and tax incentives.

In the field of automotive plastics, China can learn from Mitsubishi Chemical's approach.The "horizontal recycling" model involves establishing regional recycling centers in automobile industry clusters such as the Yangtze River Delta and the Pearl River Delta, equipped with advanced technological equipment like AI sorting and microwave depolymerization. Meanwhile, blockchain technology is used to achieve full-process traceability, enhancing consumer trust in recycled materials. With the expansion of China's electric vehicle exports, establishing an efficient and low-cost recycled plastic recycling system will become a key path to achieving the "dual carbon" goals.

【Copyright and Disclaimer】This article is the property of PlastMatch. For business cooperation, media interviews, article reprints, or suggestions, please call the PlastMatch customer service hotline at +86-18030158354 or via email at service@zhuansushijie.com. The information and data provided by PlastMatch are for reference only and do not constitute direct advice for client decision-making. Any decisions made by clients based on such information and data, and all resulting direct or indirect losses and legal consequences, shall be borne by the clients themselves and are unrelated to PlastMatch. Unauthorized reprinting is strictly prohibited.

Most Popular

-

Chuan Jinheng Auto Safety System Jinzhou Factory Catches Fire

-

List Released! Mexico Announces 50% Tariff On 1,371 China Product Categories

-

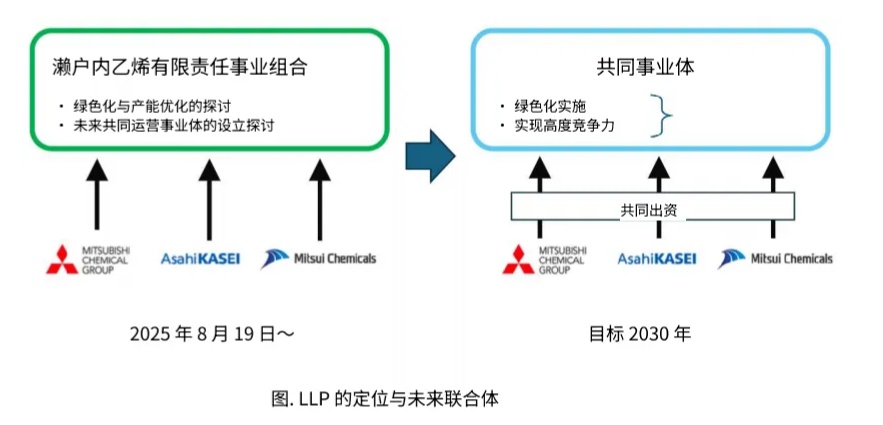

Asahi Kasei, Mitsui, Mitsubishi Establish New Company! Sinopec, BASF Already Positioned

-

Modern Dispersions To Launch PFS-Free Black Masterbatch at K Show

-

Mega Ton Project Mechanical Completion! Review of South China Large Ethylene