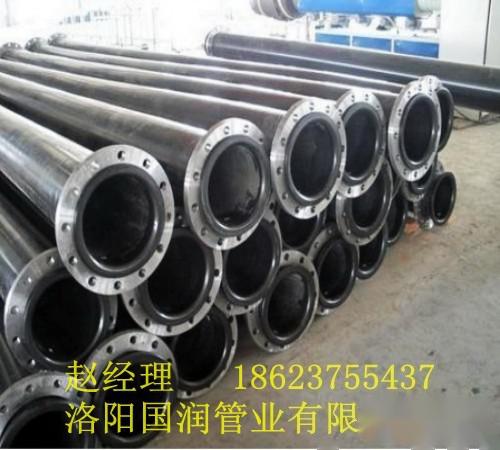

Yunnan Sand Suction Pipe

Luoyang Guorun Pipe Industry Co., Ltd. specializes in the production of ultra-high molecular weight polyethylene pipes, wear-resistant pipes, and tailings pipes. They are widely used in metallurgy and mining (slurry transportation, grouting backfill), power (fly ash transportation), dredging and sand suction (sludge transportation in lake dredging, sand suction pipes for sand suction boats), petroleum, natural gas, textiles, papermaking, chemical engineering, machinery, electrical, and other industries. They can be used for transporting various corrosive and high-wear liquids or solid-liquid mixtures, such as various acidic liquids, alkaline liquids, crude oil, tailings, slurries, coal-water slurries, and for discharging ash and slag in power plants.

Ultra-high molecular weight polyethylene pipes are made by continuously extruding ultra-high molecular weight polyethylene using special extruders and specially designed molds. This type of pipe has excellent comprehensive performance, high wear resistance, low-temperature resistance, corrosion resistance, self-lubrication, and impact resistance, which are superior to most plastics. Its wear resistance is better than that of polytetrafluoroethylene, nylon, carbon steel, etc., and it can work for a long time under conditions ranging from -169 to +80℃, making it known as the 'amazing' engineering plastic!

Yunnan Sand Suction Pipe has the following advantages:

1. High wear resistance: The molecular chains of ultra-high molecular weight polyethylene are particularly long, resulting in wear resistance that is 4-7 times higher than that of steel pipes and stainless steel pipes when transporting various slurries.

2. High tensile strength and high impact resistance: The tensile strength of ultra-high molecular weight polyethylene transport pipes is 2.5 times that of PE80 and 2 times that of PE100, while its environmental stress cracking resistance is more than 1 time that of PE100, and its fatigue resistance is over 30 times that of PE100.

3. Corrosion resistance: UHMWPE pipes have excellent chemical resistance; except for strong oxidizing acidic liquids, they can resist various corrosive media (acids, bases, salts) and organic media (except naphthalene solvents) within certain temperature and concentration ranges.

4. Non-scaling: The self-lubricating and non-adhesive properties of ultra-high molecular weight polyethylene, along with a low friction coefficient, prevent scaling. The inner wall of the pipes produced using special processes is resistant to corrosion, wear, and scaling, resulting in very low flow resistance, which can maintain flow rate and volume over long periods. Their inner diameter can be reduced by 15.4% compared to steel pipes. This feature is significant for thermal power plants used in ash discharge systems.

5. Durable sand suction pipes with high pressure resistance: can withstand working pressures of up to 5Mpa.

6. Durable sand suction pipes have a long service life: under normal pressure and temperature ranges, their lifespan can reach up to 10 years.

7. Durable sand suction pipes are hygienic and non-toxic.

Yunnan Sand Suction Pipe Engineering Cases:

1. Guangxi Nanning Sand and Stone Company: 10-inch sand suction pipeline, 500 meters.

2. Luang Prabang Hunan Sand and Stone Co., Ltd: 12-inch sand suction pipe, 1000 meters.

3. Zhoushan Wanrong Shipping Company: 20-inch sand suction pipeline, 500 meters.

4. Export to Singapore: 8-inch sand suction pipe, 2000 meters.

5. Hong Kong Chuangyi Shipping Company: sand suction pipe (1000m, 12-inch sand suction pipe Φ700*1200mm buoy).

6. Tianjin Junlian Shipbuilding Marine Engineering Co., Ltd: 1000 meters, 6-inch sand suction pipe and Φ500*800mm buoy).

7. Tianjin Hongda Dredging Co., Ltd: 2300 meters, 12-inch sand suction pipe and Φ1100*1100mm buoy).

8. GAMLA (Nigeria) Ltd: produced in South Africa, 1500 meters, 8-inch sand suction pipe and buoy Φ500*800mm).

Contact Person:Manager Zhao

Mobile:18623755437

Phone: 0379-60692512

Fax: 0379-65260950

Company Website: www.lygrsjw.com

Email: 874689613@qq.com

Factory Address: Henan Province, Luoyang City, Mengjin County, Matun Town, Zhejiang Business Industrial Park

Welcome to visit our factory and order pipes; we will provide you with the best product service!