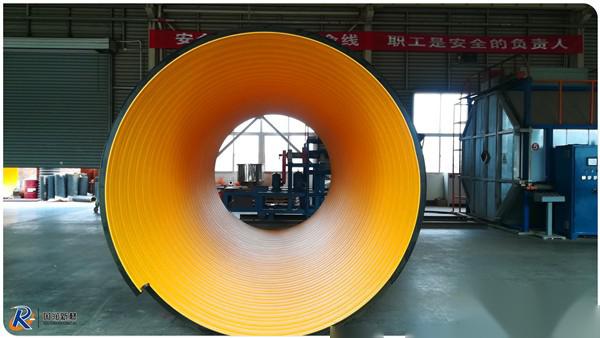

Steel Belt Sewage Pipe Steel Belt Buried HDPE Sewage Pipeline

HDPE steel belt corrugated pipe: This is a type of PE composite material developed by adopting advanced foreign metal composite technology. The product complies with CJ/T225-2006 standard. The wall structure of the pipe consists of 3 layers, with high-density polyethylene as the matrix and spiral-wound high-strength steel belt as the reinforcement. Using a unique manufacturing process, the steel belt and high-density polyethylene are melted together, providing both the high rigidity of steel and the flexibility of plastic pipes, addressing the shortcomings of steel and the hardness issues of plastic pipes.

Steel Belt Sewage Pipe Steel Belt Buried HDPE Sewage Pipeline Features:

1. Chemical Resistance: Not affected by pollution, wastewater, or chemical corrosion; does not corrode due to decomposing substances in the soil;

2. Impact Resistance: The pipe wall uses a 'U' shaped structure, resistant to impact and pressure, does not rupture under foundation subsidence, and has strong recovery after deformation, showing good adaptability to the foundation;

3. Aging Resistance: The pipe is usually black and can withstand direct sunlight during storage and construction;

4. Cold Resistance: The pipe will not crack or leak at temperatures as low as -60°C;

5. Lightweight: Easy to transport and convenient for construction, weighing only 1/8 of the weight of concrete pipes; only an excavator is needed for burial, without the need for large equipment;

6. Easy Connection: The pipes can be connected outside the trench, then pushed into the trench by an excavator, reducing project time and costs;

7. Excellent Wear Resistance: More wear-resistant than steel and concrete pipes, with strong ability to transport domestic wastewater and sludge;

8. Superior Drainage Flow: The internal surface is smooth, reducing friction and allowing for fast drainage;

9. Economic Efficiency: Low construction, management, and maintenance costs;

10. Environmental Impact: HDPE is an environmentally friendly material, harmless to land and other environments, and can be fully recycled.

Steel Belt Sewage Pipe Steel Belt Buried HDPE Sewage Pipeline Connection Methods:

1. Electric Heat Fusion Band Connection

The electric heat fusion band connection uses specially made electric heat fusion bands. The body is made of polyethylene with embedded heating wires on the inner surface. When powered, the electric heat fusion shaft extrudes the melted material, expanding and forming pressure. The polyethylene on both sides of the interface diffuses into each other. After disconnecting the power, a reliable connection is formed once it has fully cooled and solidified.

2. Heat Shrink Sleeve (Band) Connection

The materials used for heat shrink sleeve (band) connection are polyethylene sleeves (bands) and reinforced fiber mesh. After being cross-linked by electron radiation, they are expanded and cooled to set, with heat fusion adhesive applied to the inner wall. During connection construction, the sleeve is placed at the joint of the pipes to be connected, and heated with a blowtorch to cause the heat shrink sleeve (band) to shrink and fuse with the heat fusion adhesive on the inner wall, forming a sealed, leak-proof joint with certain strength.

3. Clamp and Sealing Band Connection

The clamp and sealing band connection involves using split metal clamps (which consist of two halves, and for larger diameters, can be composed of four quarters) to clamp the two pipe sections together from the outside circumference. The clamps have protrusions or flanged edges to catch adjacent projections, thus fixing the two pipe sections axially. An elastic sealing band is placed between the clamp and the pipe, and elastic sealing blocks are inserted at both ends of the spiral groove joint of the steel belt reinforced polyethylene corrugated pipe, relying on the tightening force of the clamp to compress the elastic sealing band and sealing blocks to achieve sealing and leak-proof requirements.

4. Hot Melt Extrusion Welding

Extrusion welding uses a handheld welding extruder to melt and extrude polyethylene material, welding the polyethylene on both sides of the joint together (the handheld welding unit is a small diameter extruder capable of melting and extruding the supplied polyethylene welding rod. Meanwhile, the polyethylene part to be welded should be preheated using hot air).

Applications of Steel Belt Corrugated Pipe:

1. Water Storage Systems: Systems for retaining slowly flowing water

2. Municipal Engineering: Large diameter buried drainage and sewage pipes

3. Road Engineering: Drainage and seepage pipes for railways and highways

4. Construction Engineering: Rainwater pipes, underground drainage pipes, sewage ventilation pipes, etc.; leachate collection pipes for landfills

5. Large Port and Dock Projects: Drainage and sewage pipes for large airports, ports, and dock projects

6. Sports Venues: Drainage pipes for golf courses, football fields, and other sports venues

7. Mining: Ventilation, air supply, drainage, and slurry pipes for mines

8. Industry: Sewage pipes for industrial applications

9. Water Conservancy Projects: Water source pipes, irrigation pipes, and water transportation and drainage for hydropower stations

10. Agricultural Engineering: Irrigation and drainage in farmland, orchards, and forest belts

11. Communication Pipes: Railway and highway communication, communication electrical systems, and optical cable protection pipes

Sales Manager: Manager Sun 13698887149 /0379-65227507

Factory Location: China. Luoyang Airport Industrial Cluster Zone. Zhejiang Business Industrial Park