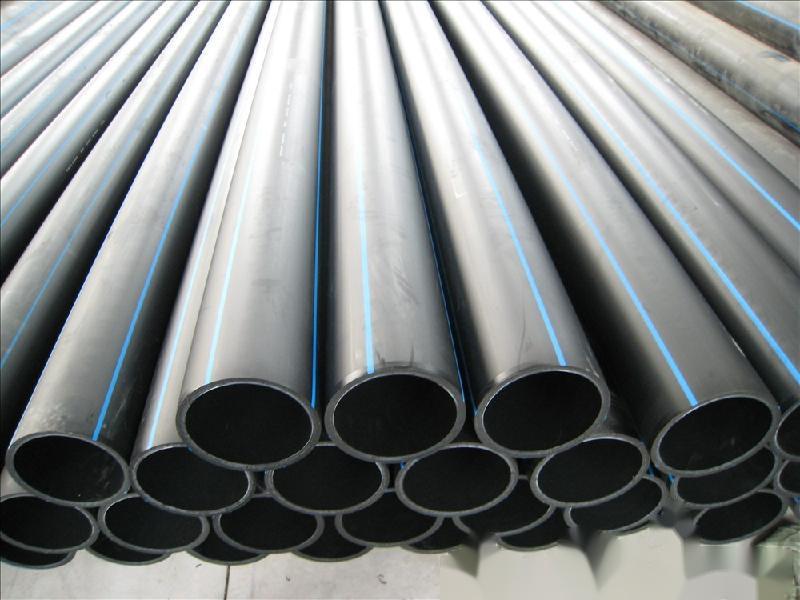

HDPE Water Supply Pipe, HDPE Water Supply Pipe, Xuchang PE Pipe

Luoyang Guorun specializes in the production of PE pipes, PE pipes, and PE water supply pipes. We offer a complete range of pipes. Business Manager: Manager Zhao 18623755437

PE is polyethylene plastic, a basic type of plastic, with products like plastic bags and cling film made from PE. HDPE is a high-crystallinity, non-polar thermoplastic resin. The natural state of HDPE appears milky white and is semi-transparent to a certain degree in thin sections. PE has excellent resistance to most chemicals used in daily life and industry.

The welding of PE pipes, φ110PE water supply pipes, and PE pipe butt joints is a method that provides high reliability across a range of diameters and pressure processes: the ends of heated pipes are joined using a tool called "mirror" under defined contact pressure and temperature. The ends are quickly brought into contact and held under pressure during the cooling process.

PE pipes can be categorized into medium density polyethylene pipes and high density polyethylene pipes. They are divided into SDR11 and SDR17.6 series based on wall thickness. The former is suitable for transporting gaseous artificial coal gas, natural gas, and liquefied petroleum gas, while the latter is mainly used for transporting natural gas. Compared to steel pipes, PE water supply pipes have a simpler construction process, certain flexibility, and most importantly, do not require anti-corrosion treatment, which saves a substantial amount of procedures. However, they are not as mechanically strong as steel pipes, and other construction precautions regarding safety distances for heating must be observed. Additionally, they should not be exposed to sunlight and air, and are sensitive to chemicals, preventing leaks from sewage pipes that could cause harm. In China's municipal pipe market, PE water supply pipes, sewage pipes, and gas pipes are two major application markets.

High-Density Polyethylene Pipe: HDPE Water Supply Pipe, Xuchang PE Pipe

Among all engineering plastics, HDPE has the best wear resistance, which is remarkable. The higher the molecular weight of the PE water supply pipe, the more abrasion-resistant the material is, even exceeding that of many metals (such as carbon steel, stainless steel, bronze, etc.). Under conditions of strong corrosion and high wear, its lifespan is 4-6 times that of steel pipes and 9 times that of ordinary polyethylene; it also improves transportation efficiency by 20%. PE pipes are flame-retardant and have good anti-static properties, all meeting standard requirements. The underground service life exceeds 20 years, with significant economic benefits. They are impact-resistant and wear-resistant, showing significant dual-resistance effects. Currently, the quality of mining pipes produced by manufacturers varies greatly, so it is essential to find reputable manufacturers. We recommend the Rongcheng brand mining pipes, which hold national patents. In coal mining enterprises, the advantages of easy installation and long lifespan of HDPE mining pipes are irreplaceable. In recent years, the development momentum of HDPE mining pipes has been strong!

HDPE Water Supply Pipe: HDPE Water Supply Pipe

When choosing Xuchang PE pipes, users should pay special attention to the following points:

1. Special attention should be paid to the selection of raw materials for plastic pipes. There are thousands of grades of polyethylene raw materials available in the market, with prices as low as a few thousand yuan per ton. Products made from such raw materials are unsuitable for construction and could lead to significant rework losses. HDPE water supply pipe

2. When selecting pipe manufacturers, choose regular and professional manufacturers. We recommend the Jiqing brand pipes, which have undergone multiple certifications.

3. When choosing to purchase PE water supply pipes, it is essential to conduct an on-site inspection of the manufacturing capabilities of the producer.

PE water supply pipes must withstand certain pressures, so it is generally advisable to use high molecular weight, mechanically superior PE resins, such as HDPE resins. LDPE resins have low tensile strength, poor pressure resistance, low rigidity, poor dimensional stability during molding and processing, and are difficult to connect, making them unsuitable as materials for water pressure pipes. However, due to their high sanitary indicators, PE, especially HDPE resin, has become a commonly used material for producing drinking water pipes. The melt viscosity of HDPE resin is low, with good flow properties, making it easy to process. Therefore, the selection range for its melt index is also wide, usually MI ranges from 0.3 to 3g/10min. The required welding time for each joint is determined by adding the values obtained based on the material of the pipe within each time range. The cooling time for the welded pipe ends is generally 10-12 times the wall thickness.

Contact Person:Manager Zhao

Mobile:18623755437

Phone: 0379-60692512

Fax: 0379-65260950

Company Website: www.lygrsjw.com

Email: 874689613@qq.com

Factory Address: Zhejiang Business Industrial Park, Matun Town, Mengjin County, Luoyang City, Henan Province

Welcome to purchase our polyethylene pipes, and we will provide you with quality product services!