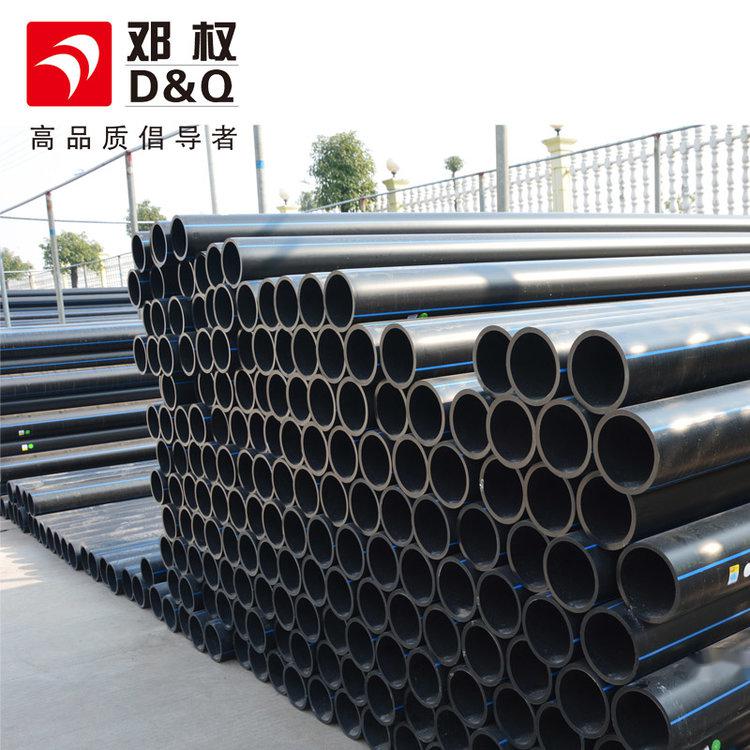

PEWater Supply Pipe Fittings

Product Material Overview

PE (High-Density Polyethylene) is an eco-friendly and healthy drinking water pipeline made from imported PE100 raw materials, manufactured according to GB/T13663 standards. The product has good weldability and resistance to environmental stress cracking, with performance meeting international and national standards.

PE pipes are mainly used for water supply and drainage, mining pipelines, chemical and pharmaceutical wastewater, and the transportation of solid or mixed media such as flowing sand and mortar. The internal resistance of PE pipes is 25% lower than that of metal pipes, which greatly improves transportation efficiency.

The raw material for PE is abundant. From the molecular formula structure (C2H4), PE has a simple polymer molecular structure. In its development, PE pipes have continuously overcome their shortcomings. The heating welding of PE requires a certain operational space and skilled technical expertise. Later, electric heating welding sleeves were invented, connecting two pipe sections or fittings through an electric heating welding sleeve. This connection method is used for connecting PE pipes in trenches or in narrow construction spaces. The material properties of PE pipes are also improving, evolving from PE63 and PE80 to PE100, and in the future, it will develop to PE115. PE100 means that at 200°C, this grade of PE material can maintain a low strength (MRS) of 10Mpa after 50 years. PE80 is rated at 8.0Mpa. As the grade of PE material increases, for the same pipe, the wall thickness of PE115 pipes is lower than that of PE100 pipes. Under the premise of meeting requirements, the wall thickness of PE pipes is reduced, which decreases the amount of PE material used, lowers costs, and is beneficial for the application of PE pipes in large-diameter pipelines.

The connection of PE pipes requires heating and also has a required cooling time, with each welding taking about 20 minutes. The larger the diameter of the pipe, the longer the heating and cooling times, thus extending the installation period of PE pipes.

Product Features

1. Long service life. Under normal conditions, the lifespan can reach up to 50 years.

2. Good hygiene. No scaling, no bacterial growth, solving the problem of secondary pollution of drinking water. Complies with GB/T17219 safety evaluation standards.

3. Resistant to various chemical media corrosion, with no electrochemical corrosion.

4. Smooth inner wall with extremely low friction coefficient, improving the medium's transit capability and exhibiting excellent wear resistance.

5. Good flexibility, high impact strength, and resistance to strong shocks and twists.

6. Unique thermal fusion butt and socket welding technology ensure that the joint strength is higher than that of the pipe body, guaranteeing the safety and reliability of the joints.

7. Simple welding process, convenient construction, and low project costs.

8. Lightweight, making transportation and installation convenient.

Product Applications

Urban water supply PE pipelines have comprehensive advantages such as safety, hygiene, and ease of construction, making them the ideal material for urban water supply.

Natural gas and gas transmission pipelines have become the choice for medium and low-pressure natural gas transmission due to the reliability, stability, ease of construction, and corrosion resistance of PE pipes.

In the food and chemical industries, PE pipes possess unique resistance to chemical corrosion, suitable for transporting or discharging various acid, alkali, and salt solutions, with a long service life and low costs for maintenance.

The wear resistance of PE pipes for transporting sand and mud is four times that of steel pipes, making them widely used for transporting sand, fly ash from power plants, and mud for river dredging.

Replacing cement pipes, cast iron pipes, and steel pipes can be accomplished without extensive excavation. PE pipes can be directly inserted into old pipes for replacement, resulting in low project costs and short construction times, especially suitable for pipeline replacements in old urban areas.

Landscaping and greening require a large number of water supply pipelines. PE pipes are cost-effective and worth promoting extensively.

Other applications: PE pipes can also be widely used in other fields such as electric power, communication conduits, agricultural irrigation, siphon drainage, landfill, geothermal air conditioning, deep-sea aquaculture, buried fire-fighting pipelines, and more.

Dengquan Plastic Industry Technology (Hunan) Co., Ltd. has been producing and operating PVC series pipes and fittings, PPR series pipes and fittings, PE series pipes and fittings, HDPE silicon core pipes, and more, with a diverse range of products and complete specifications. Direct sales from the manufacturer, quality assurance. Welcome to inquire and negotiate.

For details, please contact: Fan Mingyan (Manager) 15364168798

0736-7822001