Building Rainwater Collection Pipe and Sewage Pipe Classification

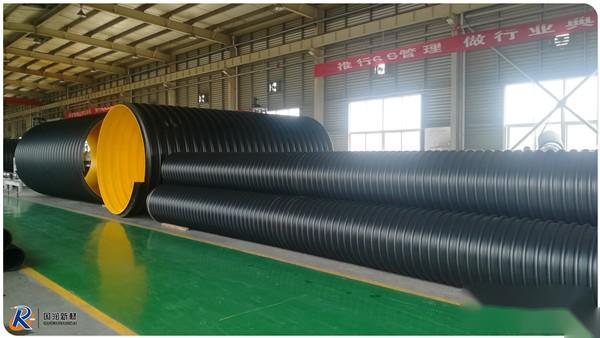

The steel belt reinforced spiral corrugated pipe combines the advantages of steel and plastic. Continuous steel belts are pressed into an approximate “U” shape and wound between the inner and outer layers of thermally fused polyethylene. This combination allows the pipe to achieve ring stiffness levels of SN8, SN12.5, and SN16, solving the corrosion problem of steel and breaking through the limitation that large diameter all-plastic buried drainage pipes generally can only reach SN8 for ring stiffness.

The elastic modulus of steel is nearly 200 times that of polyethylene. Combining the advantages of metal and plastic is evidently an ideal way to achieve high stiffness with low consumption, enabling the organic combination of steel's high rigidity and strength with plastic's corrosion resistance, wear resistance, and flexibility, thus leveraging the advantages of both while compensating for their disadvantages, achieving a balance of high performance and low cost.

Building Rainwater Collection Pipe and Sewage Pipe ClassificationConstruction Methods

The construction of steel belt corrugated pipes differs from that of ordinary concrete pipes. If the construction personnel are not familiar with the characteristics of steel belt corrugated pipes and use traditional reinforced concrete pipeline construction techniques to install them, it will affect the construction quality and cannot guarantee the normal operation of the pipes.

1) The steel belt corrugated pipe is lightweight, and it must be ensured that the pipe does not float during the construction period.

2) The compactness of the bottom cushion layer and backfill soil determines the load capacity of the “pipe and soil” system and the radial deformation rate of the pipe. To achieve the effect of “pipe-soil interaction,” the compactness of the bottom cushion layer and backfill soil must meet the design requirements.

3) To accomplish the above two points, it is essential to ensure that there is no water accumulation in the trench during backfilling. Backfilling should not be done with water present, and mud or organic matter should not be used for backfill. The backfill soil must not contain stones, bricks, or other hard debris; in areas with high groundwater, the groundwater level should be lowered to below the lowest point in the trench. Backfilling can only stop when the project is unaffected by groundwater or when the foundation strength and pipe buoyancy resistance are satisfied.

Building Rainwater Collection Pipe and Sewage Pipe ClassificationFeatures:

1, The pipe material is corrosion-resistant PE material, which will not be corroded by acids, alkalis, and oils in sewage and wastewater.

2, The product is a flexible pipe that has excellent recovery performance when subjected to external impact and is not easily broken under ground subsidence.

3, The base material of the pipe has a characteristic that can be effectively used for more than 50 years at 20℃, thus the pipe has strong anti-aging properties.

4, In an environment of 60℃, the pipe will not freeze or leak.

5, The weight of the pipe is only 1/8 of that of the same specification concrete pipe and 2/3 of traditional wound plastic structure pipes, making it easy to transport and construct without the need for large construction equipment.

6, The lightweight pipe is easy to connect and requires low excavation engineering standards, significantly saving construction time and costs in urban drainage engineering projects.

7, The connection methods are diverse and simple, allowing for quick and easy on-site construction.

8, The pipe has a low friction coefficient and strong medium transport capability.

9, The internal surface is smooth, resulting in low friction resistance and fast drainage speed.

10, Polyethylene itself is a non-toxic recyclable material that will not pollute the environment.

11、Excellent drainage flow: The internal surface is smooth, reducing friction and allowing for fast drainage speed. Steel belt corrugated pipe refers to a plastic pipe with a smooth inner wall and a corrugated outer wall (the corrugated shape can be right-angle, trapezoidal, sinusoidal, etc.), which is formed by simultaneously extruding the corrugated outer wall and a smooth inner wall. In addition to having all the characteristics of ordinary plastic, such as good corrosion resistance, high insulation, and low internal flow resistance, it also uses a special hollow ring stiffness and good strength and toughness. Under the same strength and stiffness requirements, using double-wall corrugated pipes can save material by 30%-50% compared to ordinary plastic pipes, providing good technical economy while being easy to transport and install, reducing the labor intensity of construction personnel, and lowering the total engineering cost.

Sales Manager: Manager Sun 136 9888 7149, 0379-6522 7507

Factory Address: China.Luoyang Airport Industrial Cluster Zone.Zhejiang Business Industrial Park