Hubei Sand Suction Pipe

Large Diameter Sand Suction Pipeline features are as follows:

1、Lightweight only one-eighth of steel pipes; connected by movable flange bolts, easy to install, disassemble, and transport, reducing construction time and improving efficiency. After external force damage, repairing and replacing pipeline sections saves costs.

2、Good Toughness ultra-high sand suction pipes have high strength under tension, are elastic, and do not crack under wall extrusion or internal and external force impacts; plastic pipes are directly connected and can bend in water with 4-8 pipes bending 360 degrees, providing good resistance to wind and waves; when connected on land, they can be directly connected in uneven areas within 30 degrees without the need to repair the ground.

3、Strong Wear Resistance ultra-high molecular sand suction pipes are 4-8 times that of steel pipes, with a longer service life; the pipe material has strong corrosion resistance, soaking in seawater for 50 years without any changes; UV resistant and aging resistant, can be used for 5-8 years depending on the sand content.

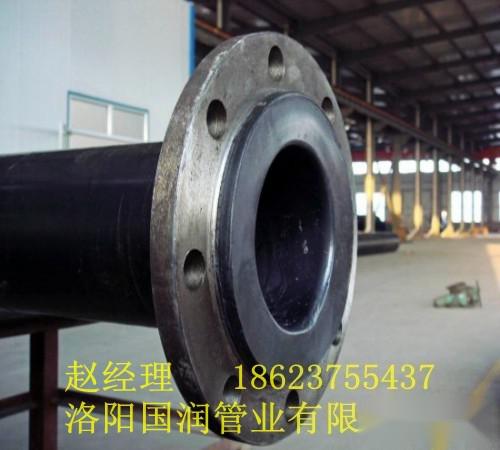

4、Easy Installation the sand suction pipe has movable metal flanges on both ends; the entire finished pipe has no welds, and pipes are directly connected using bolts through movable flanges; the pipe mouth is lined with a steel ring, ensuring that the pipe mouth does not deform, crack, or leak during long-term installation and disassembly, ensuring high efficiency in the transportation project.

5、Low Friction Coefficient, strong weather resistance the inner and outer walls of the ultra-high sand suction pipe are smooth, with extremely low friction coefficients, resulting in a transportation efficiency 20%-30% higher than steel pipes, and can operate in temperatures from -40℃ to 60℃, adapting to harsh climate temperature changes.

6、Low Cost whether used on land or in water for long periods, the total project cost is low, efficiency is high, and it is safer and more convenient.

Application Fields of Hubei Sand Suction Pipe:

Mining Industry: slurry transportation pipelines, high-pressure water supply, and gas pipelines in coal mines.

Coal Industry: transportation of coal powder, coal-water slurry, air supply, exhaust, drainage systems in mines, and desulfurization systems.

Chemical Industry: transportation of highly corrosive media, brine, salt slurry, and raw salt in the salt chemical industry.

Mining Industry: slurry transportation pipelines, high-pressure water supply, and gas pipelines in coal mines.

Dredging Projects: transporting mud and sand for dredging projects in rivers, lakes, ports, and docks.

Marine Engineering: transporting seawater and fresh water in seawater desalination.

Municipal Engineering: sewage treatment, domestic water supply, and gas, natural gas transportation.

Hubei Sand Suction Pipe engineering project case studies:

1、Nanning Sand and Gravel Company, Guangxi 10-inch sand suction pipeline 500 meters

2、Luang Prabang Hunan Sand and Gravel Co., Ltd., 12-inch sand suction pipe, 1000 meters

3、Zhoushan Wanrong Shipping Company 20-inch sand suction pipeline, 500 meters

4、Export to Singapore 8-inch sand suction pipe, 2000 meters

5、Hong Kong Chuangyi Shipping Company sand suction pipe (1000m Φ300 ultra-high molecular polyethylene pipe Φ700*1200mm buoyancy)

6、Tianjin Junlian Marine Engineering Technology Co., Ltd. 1000 meters Φ159 ultra-high molecular polyethylene sand suction pipe and Φ500*800mm buoyancy)

7、Tianjin Hongda Dredging Co., Ltd. (2300 meters Φ325 ultra-high molecular polyethylene sand suction pipeline and Φ1100*1100mm buoyancy)

8、GAMLA(Nigeria) Co., Ltd. (producing 1500 meters Φ200 sand suction pipe and pipe buoyancy Φ500*800mm)

Contact Person:Manager Zhao

Mobile:18623755437

Phone: 0379-60692512

Fax: 0379-65260950

Email: 874689613@qq.com

Website: www.lygrsjw.com

FactoryAddress: Henan Province, Luoyang City Mengjin County, Matun Town, Zhejiang Business Industrial Park

Luoyang Guorun Pipe Industry Co., Ltd. welcomes new and old customers to call for consultation and negotiation.