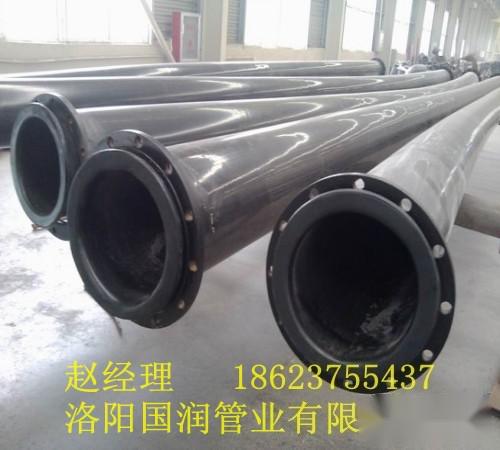

Heilongjiang Sand Suction Pipe

Sand suction pipe buoy, plastic buoy manufacturer, polyethylene buoy, water surface buoy

Sand suction pipe buoy is specially designed for sand suction and discharge pipelines, with a shell made from high compressive strength and excellent toughness medium-density polyethylene material. The plastic shell is filled with high-strength, high-buoyancy polyurethane foam material. This buoy is impact-resistant and wave-resistant, with a compact and reasonable structure, easy installation, and excellent performance, making it a preferred floating material for waterborne sludge discharge pipelines for today's sand suction pipeline customers.

Heilongjiang Sand Suction Pipe Key Features:

1. Lightweight Only one-eighth the weight of steel pipes; connected by movable flange bolts for easy installation, disassembly, and transportation, reducing startup time and improving efficiency. After external damage, pipe sections can be easily repaired or replaced, saving costs.

2. Good Toughness Ultra-high sand suction pipelines have high tensile strength and elasticity, with pipe walls that do not crack under internal and external impacts; plastic pipes can connect directly in water, capable of bending 360 degrees with 4-8 pipes, exhibiting good wind and wave resistance; on land, connections can be made directly in areas with surface irregularities within 30 degrees, without the need for ground leveling.

3. Strong Abrasion Resistance Ultra-high molecular sand suction pipes have a lifespan 4-8 times longer than steel pipes; the pipe material is highly corrosion-resistant, remaining unchanged after 50 years submerged in seawater; resistant to UV rays and aging, with a lifespan of 5-8 years depending on sand content.

4. Easy Installation The sand suction pipe features movable metal flanges at both ends; the entire finished pipe has no welds, and pipes are connected directly with bolts through movable flanges; the inner lining of the pipe ends has steel rings to ensure that they do not deform, crack, or leak during long-term installation and disassembly, ensuring high efficiency in the conveying project.

5. Low Friction Coefficient and Strong Weather Resistance The inner and outer walls of ultra-high sand suction pipes are smooth, with a very low friction coefficient, resulting in a 20%-30% higher conveying efficiency than steel pipes, with a temperature range of -40℃ to 60℃, able to adapt to harsh climatic temperature changes.

6. Low Cost Whether used on land or in water for long periods, the overall project cost is low, with high efficiency, safety, and convenience.

Heilongjiang Sand Suction Pipe Project Cases:

1. Tianjing Junlian Shipbuilding Marine Engineering Technology Co., Ltd. (1000 meters Φ159 ultra-high molecular sand suction pipe and Φ500*800mm buoy)

2. Tongjiang City Sanjiangkou Sand Field, Heilongjiang (1000m Φ325 ultra-high molecular sand suction pipe and Φ700*1200mm pipe buoy)

3. Guangzhou Hangtong Shipbuilding Co., Ltd. (1300 meters Φ250 dredging pipeline and Φ500*800mm buoy)

4. Shandong Provincial Water Conservancy Dredging Engineering Office φ560mmX1550mmX1400mm buoy 315 pairs

5. Jining Port and Navigation Engineering Office φ600mmX1400mmX1700mm buoy 280 pairs

6. Jiangsu Oriental Ecological Dredging Engineering Co., Ltd. φ315mmX1100mmX1100mm buoy 150 pairs

7. Liaoning Jinbowan Port and Navigation Engineering Co., Ltd. φ480mmX1300X1300mm buoy 270 pairs

8. Guangdong Jindonghai Group Co., Ltd. φ750mmX1600mmX2000mm buoy 237 pairs

9. Yingkou Port Dredging Engineering Co., Ltd. φ780mmX1600X1900mm buoy 315 pairs

Contact Person: Manager Zhao

Mobile:18623755437

Phone: 0379-60692512

Fax: 0379-65260950

Email: 874689613@qq.com

Website: www.lygrsjw.com

Factory Address: Mengjin County, Luoyang City, Henan Province, Zhejiang Business Industrial Park

Luoyang Guorun Pipe Industry Co., Ltd. welcomes new and old customers to call for consultation and negotiation.