Hebei Sand Pump Pipe

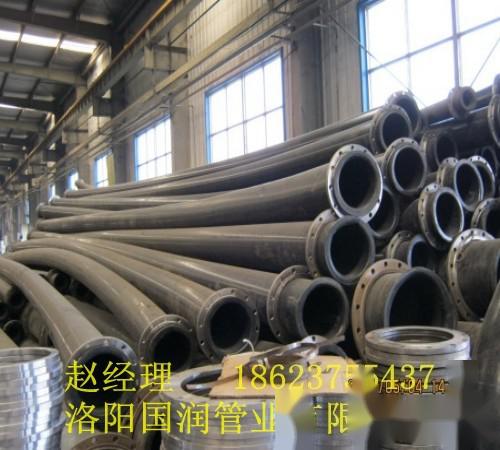

Luoyang Guorun specializes in the production of large-diameter sand pumping pipes and large-diameter slurry pipes, providing high-quality pipes.

The polyethylene sand pump pipe is lightweight, flexible, high-strength, and elastic. The pipe wall does not break when folded, compressed, or subjected to internal and external impacts; it can bend in water, effectively resisting wind and waves; on land, it can be directly connected in areas with a surface angle of less than 30 degrees; it has strong wear resistance and a longer service life; the material of the large-diameter slurry pipe is highly corrosion-resistant, UV-resistant, and aging-resistant; the pipes are connected directly with bolts through flanges; the inner and outer walls of the pipe are smooth, with a very low friction coefficient, and the transportation efficiency of the polyethylene sand pump pipe is 20%-30% higher than that of steel pipes; whether used on land or in water for a long time, it is cost-effective, efficient, safer, and more convenient.

Hebei Sand Pump PipePipe Characteristics:

1. The large-diameter sand pump pipe made of polyethylene is lightweight, only one-eighth the weight of steel pipes; flanged connections facilitate installation, disassembly, and transportation, shortening construction time and improving efficiency.

2. The large-diameter sand pump pipe and slurry pipe have good flexibility and elasticity, and the pipe wall does not break when folded; the pipes can be directly connected, bend in water, and effectively resist wind and waves; on land, they can be directly connected in areas with a surface angle of less than 30 degrees, without the need to repair the ground.

3. The wear resistance of the large-diameter sand pump pipe made of polyethylene is 4-8 times that of steel pipes, ensuring a longer service life; the pipe material is UV-resistant and aging-resistant.

4. The length of the large-diameter sand pump pipe and slurry pipe is 8-12 meters, or customized according to customer requirements; each pipe has a movable metal flange on both ends, and the pipes are directly connected with bolts; this ensures that the pipe ends do not deform, break, or leak during long-term installation and disassembly, ensuring high transportation efficiency.

5. The inner and outer walls of the large-diameter sand pump pipe made of polyethylene are smooth, with a low friction coefficient, and the transportation efficiency is 20-30% higher than that of steel pipes.

6. The large-diameter sand pump pipe made of polyethylene is cost-effective and safer for long-term use, whether on land or in water.

Hebei Sand Pump PipeAdvantages:

1. The polyethylene sand pump pipe has high wear resistance. It has strong wear resistance and tight connections, with the inner layer made of wear-resistant rubber.

2. The large-diameter slurry pipe is impact-resistant. It reduces the recoil force on the vessel's hull and has good elasticity.

3. The large-diameter slurry pipe has good toughness. It is fatigue-resistant and kink-resistant. It has good bending capability, able to bend to 60° at 2 meters, effectively resisting wind and waves, demonstrating excellent flexibility.

4. The large-diameter slurry pipe has good weather resistance. It is resistant to oxidation and bursting.

5. The polyethylene sand pump pipe has strong pressure resistance. It can withstand negative pressure of 15 kg and positive pressure of 10 kg.

6. The polyethylene sand pump pipe has strong adhesion. It adheres well, is not easily delaminated, and is convenient for installation and use.

The polyethylene sand pump pipe and large-diameter slurry pipe applications

Hebei Sand Pump PipeProject Cases:

Guangxi Nanning Sand and Stone Company 10-inch polyethylene sand pump pipe 500 meters

Luang Prabang Hunan Sand and Stone Co., Ltd. 12-inch polyethylene sand pump pipe, 1000 meters

Zhoushan Wanrong Shipping Company 20-inch sand pump pipe, 500 meters

Hong Kong Chuangyi Shipping Company sand pump project (1000m Φ300 large-diameter slurry pipe Φ700*1200mm float)

Tianjin Junlian Marine Engineering Technology Co., Ltd. (1000 meters Φ159 ultra-high molecular polyethylene sand pump pipe and Φ500 float)

Tianjin Hongda Dredging Co., Ltd. (2300 meters Φ325 ultra-large diameter slurry pipe and Φ1100*1100mm float)

Contact Person:Manager Zhao

Mobile:18623755437

Phone: 0379-60692512

Fax: 0379-65260950

Company Website: www.lygrsjw.com

Email: 874689613@qq.com

Factory Address: Zheshang Industrial Park, Matun Town, Mengjin County, Luoyang City, Henan Province

Welcome to visit our factory and order pipes. We will sincerely provide you with quality products and services!