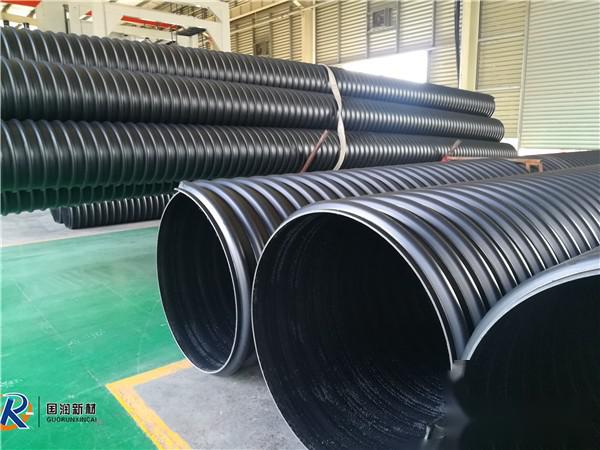

DN600 Sewage Pipe Manufacturer_600 Sewage Pipe

Henan Luoyang Guorun New Materials produces high-quality steel belt corrugated pipes at low prices, directly from the manufacturer. If you want to buy reliable products, please come to Luoyang Guorun New Materials; you can visit the factory and customize according to your needs; if you want to purchase your desired products at reasonable prices, please come to Luoyang Guorun New Materials for inspection, and I will provide you with factory prices and products, ensuring you won't be at a loss, and they will be lower than market prices; if you want to learn more about our factory, you can call me (136 9888 7149) Manager Sun.

DN600 Sewage Pipe Manufacturer_600 Sewage Pipe Specifications: DN300-3000mm, Ring Stiffness:12.5KN/m and above, Connection Methods: Hot melt belt, shrink belt, hot melt welding, etc., Service Life:50 years and above, Application Fields: Industrial sewage, municipal drainage, etc.

Sewage Pipe Material:

High-density polyethylene (HDPE) is a high-purity, non-polar thermoplastic resin. The natural state of HDPE appears milky white, with a certain degree of translucency in thin sections. PE has excellent resistance to most household and industrial chemicals; however, certain types of chemicals can cause chemical corrosion, such as corrosive oxidizers, aromatic hydrocarbons, and halogenated hydrocarbons. This polymer is non-hygroscopic and has good waterproofing properties, making it suitable for packaging applications. HDPE has excellent electrical properties, especially high dielectric strength, making it very suitable for wires and cables. Medium to high molecular weight grades have excellent impact resistance at normal temperatures and even at low temperatures of -40F.

DN600 Sewage Pipe Manufacturer_600 Sewage Pipe Features:

1. Excellent impact resistance: Good adaptability to any foundation.

2. Good chemical resistance: External anti-corrosion layer, not susceptible to pollution or corrosion.

3. Aging resistance: The outer wall is black, UV resistant, and has good aging resistance.

4. Superior drainage flow: High effective flow, low friction, fast speed; self-cleaning with minimal scaling, flow rate remains largely unchanged; additionally, the diameter is larger than other pipes.

5. Convenient connection: Can use socket connection, hot melt extrusion welding, electric heat shrink connection, heat shrink tubing (belt) connection, clamp connection, or a combination of various connection methods.

6. Lightweight and easy to transport and install: Lighter than other plastic pipes and cement pipes, with stronger performance.

7. Excellent wear resistance.

8. Low construction management and maintenance costs.

9. HDPE is an eco-friendly material, harmless to land and the environment, and can be recycled.

10. Good stability of the pipeline system.

11. Reliable ring stiffness.

Applications of Steel Belt Corrugated Pipes:

1. Municipal Engineering: Urban building water supply, drinking water, fire water, heating network return water, gas, natural gas transportation pipes, etc.

2. Oil and Gas Fields: Oil-contaminated wastewater, gas field wastewater, oil-gas mixtures, secondary and tertiary oil recovery, and process pipes.

3. Chemical Industry: Acid, alkali, and salt manufacturing, petroleum, chemical, fertilizer, pharmaceutical, textile, dyeing, rubber and plastic industries transporting corrosive gases, liquids, and solid powders as process pipes and discharge pipes.

4. Textile Dyeing: Process pipes and discharge pipes for transporting corrosive media.

5. Highways: Buried drainage pipes, cable conduits, etc.

6. Seawater Transport: Seawater desalination plants, seawater transport in coastal cities.

7. Shipbuilding: Ship sewage pipes, drainage pipes, ballast water pipes, ventilation pipes, etc.

8. Agricultural Irrigation: Deep well pipes, water filter pipes, drainage pipes, irrigation pipes, etc.

Luoyang Guorun New Materials Technology Co., Ltd. looks forward to cooperating with you!

Sales Manager: Manager Sun 136 9888 7149