DN1600PE Corrugated Pipe - Corrugated Sewage Pipe

Luoyang Guorun New Materials Technology Co., Ltd. is one of the largest manufacturers of polyethylene HDPE steel belt corrugated pipes in China. Using high-density polyethylene as raw material, the company mainly produces polyethylene steel belt corrugated pipes (HDPE) in specifications ranging from DN200mm to DN3000mm (28 models), which are widely used in municipal engineering for rainwater and sewage discharge; sewage discharge in residential communities; sewage discharge and drainage pipelines in industrial and mining enterprises; municipal sewage discharge and rainwater collection; and cable protection projects. Manager Sun 136-9888-7149

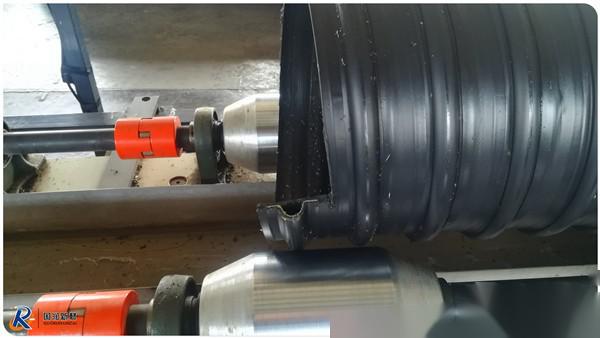

Corrugated Pipe Processing and Standards:

HDPE steel belt corrugated pipe, a steel belt reinforced PE corrugated pipe, is developed by referencing advanced foreign composite technology for metal-sourced pipes. It is a hybrid structure pipe made of PE and steel belt, conforming to the CJ/T225-2006 standard. The wall structure consists of three layers, with high-density polyethylene as the base material and high-strength steel belt as the reinforcement. Unique manufacturing processes combine the rigidity of steel with the flexibility of plastic pipes, solving the issues of anti-aging in steel and hardness in plastic pipes. This significantly improves the strength of large diameter pipes compared to spiral pipes and corrugated pipes under equivalent weight, addressing a series of heavy load problems.

The advantages of large diameter pipes are more pronounced, with current pipe diameters ranging from DN300mm to DN3000mm, maintaining ring stiffness above 8KN/m2. They are lighter in weight and stronger than cement pipes and other plastic pipes. The ring stiffness can reach four grades: SN8, SN10, SN12.5, and SN16, compensating for the past limitation where large diameter plastic underground drainage pipes could only achieve SN8 ring stiffness.

This product can adopt multiple connection methods to meet different engineering needs, effectively satisfying the requirements for reliability of sealing and ease of connection during construction. MRP, while achieving high performance, has the outstanding advantage of material savings, significantly reducing costs compared to fully plastic underground drainage pipes of the same diameter and ring stiffness.

Corrugated Pipe Specifications:

Material HDPE Ring Stiffness 8-16

Application Sewage Water Conveyance Color Black

Diameter DN300-3000mm Wall Thickness 5mm

Service Life 50 Years

Sales Contact: Manager Sun 136-9888-7149

Contact Number: 0379-65227507

Factory Address: China.Luoyang Airport Industrial Cluster.Zhejiang Business Industrial Park