Ultra-high Molecular Weight Polyethylene Rod (White): The English name is Ultra-high molecular weight polyethylene (also known as UHMW-PE), which is a thermoplastic engineering plastic with a molecular weight greater than 1.5 million. It has a molecular chain length 10-20 times that of high-density polyethylene. The longer molecular chain (higher molecular weight) gives UHMWPE its main advantages in toughness, wear resistance, and stress crack resistance. As it is a type of polyethylene, UHMWPE also possesses lubricity, chemical resistance, and excellent electrical properties similar to HDPE. Its successful development is widely regarded as one of the top ten scientific achievements of the 20th century.

Product Features:

Excellent wear resistance, good low-temperature impact resistance, self-lubricating, non-toxic, water-resistant, chemical-resistant, and better heat resistance than general PE. Its disadvantages include lower heat resistance (heat deformation temperature), poor processing and molding properties, and its surface hardness, rigidity, and creep resistance are not as good as general engineering plastics. UHMWPE has poor fluidity, with extremely high viscosity in a molten state, presenting itself as a rubber-like high-viscosity elastic body. Initially, it could only be molded by pressing and sintering methods; currently, it can also be processed by extrusion, injection molding, and blow molding.

Its mechanical properties are superior to those of general high-density polyethylene. It features outstanding impact resistance, stress crack resistance, high-temperature creep resistance, low friction coefficient, self-lubricating properties, excellent chemical corrosion resistance, fatigue resistance, noise damping, and nuclear radiation resistance.

Operating temperature of 100-110℃. Good cold resistance, can be used at -269℃. Density of 0.935g/cm3, with a molecular weight of 2 million, the product has a tensile strength of 40MPa, a breaking elongation of 350%, a flexural modulus of 600MPa, and a cantilever beam notch impact that cannot be broken. Wear amount (MPC method) of 20mm.

Application Fields:

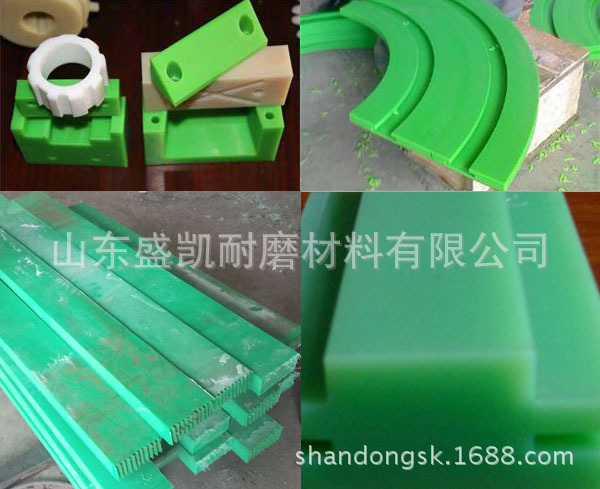

Ultra-high Molecular Weight Polyethylene Rod can replace materials such as carbon steel, stainless steel, and bronze in sectors such as textiles, papermaking, food machinery, transportation, medical, coal mining, and chemical industries. For example, in the textile industry, it is used for shuttle devices, shuttle rods, gears, couplings, flower sweeping rods, buffer blocks, eccentric blocks, rod shaft sleeves, and swing impact-resistant wear parts. In the papermaking industry, it is used for box covers, scraper boards, densification components, joints, sealing shaft rods for transmission machinery, guide rollers, scrapers, filters, etc.; in the transportation industry, it is used for linings of hoppers, silos, and chutes for powdered materials.

Ultra-high Molecular Weight Polyethylene rods can be made into various mechanical parts, including gears, worm gears, worm screws, and bearings for food machinery. In the chemical industry, it is used for pumps, valves, baffles, and filter plates. In the medical field, it can be used for valves, short surgical parts, artificial joints, and contraceptive implants. In sports, it is used for ice skating floors, rolling ball tracks, skis, and parts of motorized sleds.

Its application range is similar to that of polyamide and polytetrafluoroethylene, with wear resistance exceeding that of carbon steel, making parts such as gears, bearings, bushings, star wheels, valves, pumps, guide rails, sealing fillers, equipment linings, sliding plates, artificial joints, etc., and fibers for bulletproof vests and ropes.

Ultra-high Molecular Weight Polyethylene boasts many excellent properties; however, this outstanding engineering plastic is largely unknown, primarily due to insufficient research on its melt characteristics and the processing methods still being limited to outdated pressing and sintering processes. In recent years, with the continuous development of processing technology for ultra-high molecular weight polyethylene, its products have successfully found applications in many fields.

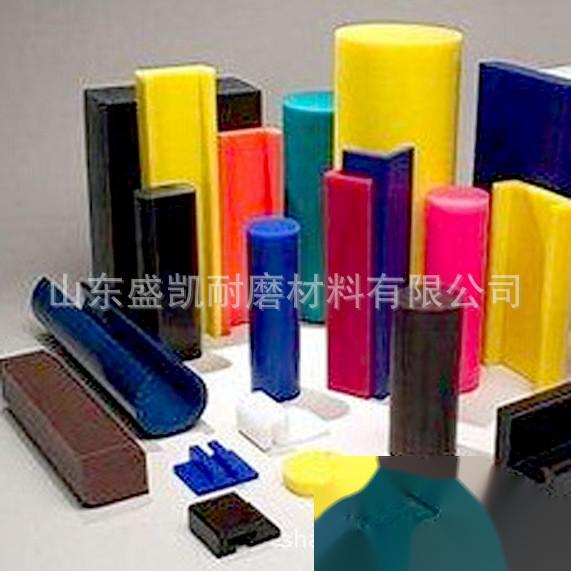

Color: Natural (white), black, other colors can be customized.

Dimensions: Rods

Diameter (Ф) x Length (L): 10mm – 250mm x 1000mm. Other specifications can be customized.

Shandong Shengkai Wear-resistant Materials Co., Ltd. specializes in the production and processing of high molecular polyethylene sheets, PE sheets, high molecular wear-resistant materials, coal bunker liners, polyethylene special-shaped parts, microcrystalline boards, cast stone plates, and other products, with a complete and scientific quality management system. The integrity, strength, and product quality of Shandong Shengkai Wear-resistant Materials Co., Ltd. have been recognized by the industry. Friends from all walks of life are welcome to visit, guide, and negotiate business.

Phone: 86-0534-2189555

Mobile: 13356271378

Fax: 86-0534-2189555

Address: A805, North Building, Sunshine New World, Decheng District, Dezhou City, Shandong

Postal Code: 253000

Website: www.shandongsk.com shandongsk.1688.com