|  |  |

Insulation Cover Adopts a double-layer protective cover made of stainless steel Reduce energy consumption of the heating system Avoid scalding of the operator due to operational errors | Injection Safety Guard A reasonable design to prevent errors caused by operational mistakes to prevent the operators from being scalded and to facilitate the operation by technical personnel Enhance work efficiency. | Material cleaning tray For convenient waste removal, a stainless steel component is configured below the nozzle. Clean the disc to avoid leaving waste material in the machine during the purging process. In the fine gaps, reducing the hassle during maintenance. |

|  |  |

Slide-type hopper mounting platform Humanized design, convenient for hopper installation, Made of high-quality steel, it is sturdy, durable, safe, and reliable. | Color touch screen Adopts a 15-inch high-definition color touch screen, A clear image makes your operation more handy, Swivel screen design for easy technical operation | Three-color alarm light In the event of a sudden situation, the alarm light will use different Color to remind you of the current conditions, Enabling you to handle all kinds of sudden events with ease, Greatly improve production management efficiency. |

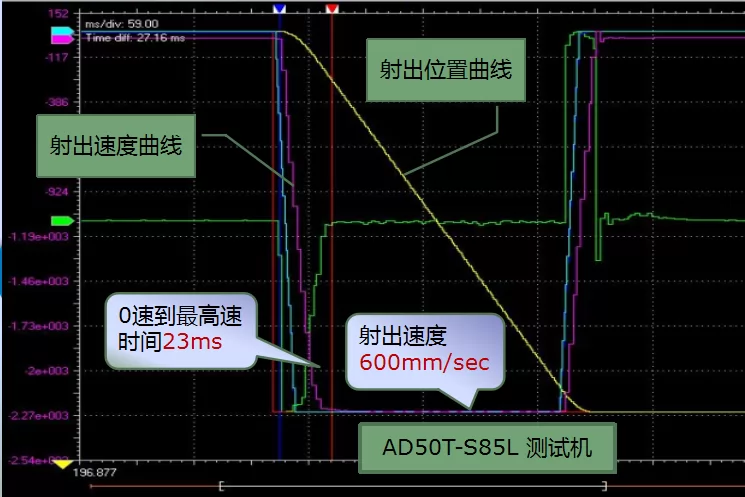

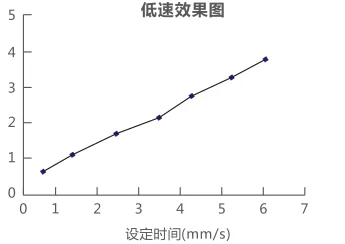

Utilizing a low-inertia load design, it enhances the responsiveness of injection speed and the traceability of low-speed injection, among other fundamental characteristics.

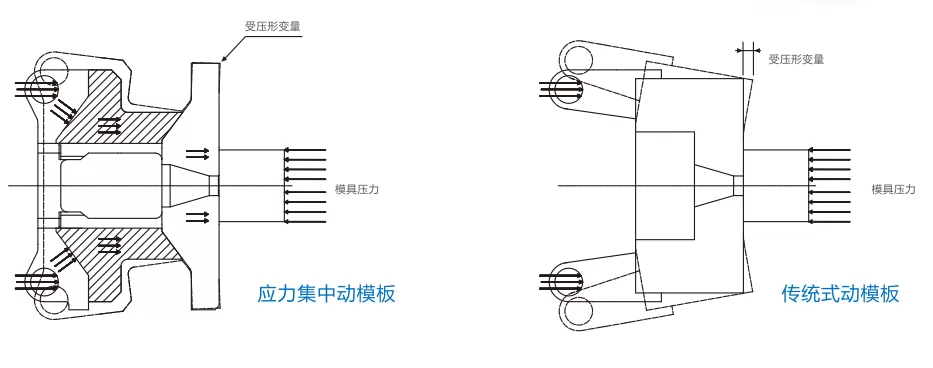

Stress concentration template design achieves uniform clamping force, improving the uneven lateral pressure and poor exhaust issues encountered with toggle-type machines, effectively extending the mold's service life. Stress concentration moving platen

|  |  |  |

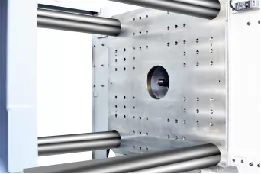

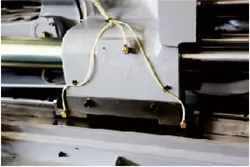

Clamping Direct Drive Direct drive structure, fast mold opening and closing response Excellent low-pressure protection. | High-standard clamping High-standard clamping force and parallelism Adjust the requirements to complete the determined lock cross state, Reduce mold wear. | Support Plate High wear-resistant, low friction moving platen support slider, Prolong the service life of the mold. | Automatic lubrication system Reduce maintenance costs. |

|  |  |  |

Fixed mold structure Optimize the structure of the fixed mold plate, Reduce template tilting and deformation. | Stress Concentration Moving Plate Optimize the structure of the moving platen, Improve the accuracy of the effective locking cross-section. | Mechanical safety rod High mechanical safety rod | frame High-strength frame design concept, adopting thick-walled construction Structural steel assembly, reducing rapid mold opening and closing vibrations. |

Whats App

Whats App

Plastmatch App

Scan the QR code

Plastmatch App

Scan the QR code 1000+ Daily Updated Global Business Leads,2M+ Global Company Database.Click to download the app.

Purchase request Download app