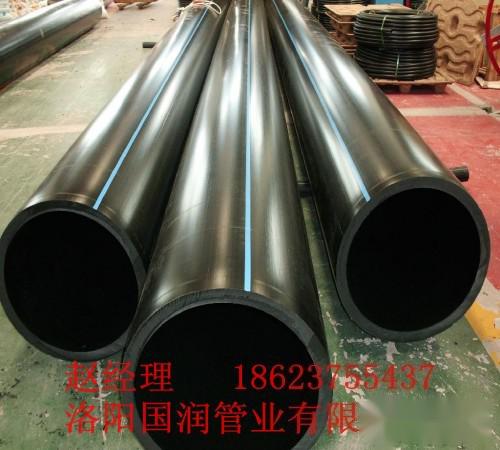

Luoyang Guorun Pipe Industry specializes in supplying HDPE Mining Pipe, PE Sand Extraction Pipeline, PE Water Supply Pipe, Polyethylene Pipeline

The welding of PE sand extraction pipelines and the butt welding of PE pipes provide high reliability within a range of diameters and pressure processes: the ends of the heated pipes are rapidly brought into contact and held under pressure during the cooling process using a tool called contact pressure and temperature defined "mirror".

HDPE mining pipe is a type of polyethylene plastic, which is a basic plastic; plastic bags, cling film, etc. are all made from PE. HDPE is a crystalline, non-polar thermoplastic resin. The original state of HDPE appears milky white and is somewhat translucent in thin sections. PE exhibits excellent resistance to most chemicals used in daily life and industry.

90PEDrain Pipe,Polyethylene PipelineChemical Properties:

Polyethylene is resistant to various organic solvents and corrosion from multiple acids and bases, but not to oxidizing acids such as nitric acid. Polyethylene will oxidize in oxidizing environments.

90PEDrain Pipe,Polyethylene PipelinePhysical Properties:

Polyethylene can be considered transparent in film form, but in bulk form, it scatters light strongly due to the presence of a large number of crystals, making it opaque. The degree of crystallinity of polyethylene is influenced by the number of side chains; the more side chains there are, the harder it is to crystallize. The melting temperature of polyethylene crystals is also affected by the number of side chains, ranging from 90°C to 130°C; the more side chains, the lower the melting temperature. Single crystals of polyethylene can usually be prepared by dissolving high-density polyethylene in a solvent at temperatures above 130°C.

90PEDrain Pipe,Polyethylene Pipeline Specifications and Connection Methods:

The diameters of PE sand extraction pipelines range from DN16 to DN315, divided into 18 levels. The pressure ratings range from 0.25Mpa to 1.0Mpa, with a total of 4 levels.

HDPE water supply pipes melt between temperatures of 190°C and 240°C. Utilizing this property, the two melted parts of the pipe (or fittings) are brought into sufficient contact and maintained under appropriate pressure, allowing them to fuse firmly upon cooling. Therefore, the connection method for PE pipes differs from that of U-PVC pipes, typically employing electric heat fusion and hot melt butt fusion methods. Depending on the diameter size, specific methods can be divided as follows: for DN≤63, injection molded heat fusion socket connections are used; for DN≥75, hot melt butt connections or electric fusion socket connections are used; flanged or threaded connections are used when connecting with different materials.

For pipeline repair methods, there are expansion pipe construction methods and inner lining HDPE methods.

90PEDrain Pipe, Polyethylene Pipeline Application Areas:

Polyethylene pipelines are mainly used in: municipal engineering water supply systems, indoor water supply systems for buildings, outdoor buried water supply systems, as well as buried water supply systems for residential communities and factories, old pipeline repairs, water treatment engineering pipeline systems, and industrial water pipes for gardens, irrigation, and other fields.

However, it should be noted that HDPE pipelines cannot be used for hot water pipelines.

90PEDrain Pipe,Advantages of Polyethylene Pipeline in Applications:

HDPE water supply pipelines are widely used mainly due to their unique advantages that other pipes cannot match:

1. Easy to weld and form a complete sealed seepage-proof system. When laid along trenches, it can reduce the amount of earthwork excavation and the quantity of fittings used.

2. Light weight and easy to install and handle;

3. Strong wear resistance and excellent hydraulic performance; buried pipelines do not require outer layer protection. Suitable for earthquakes and areas with soil subsidence, and can also be laid using the sinking method at riverbeds.

4. Resistant to chemical corrosion, which can withstand internal, external, and microbial corrosion, and has strong anti-corrosive properties. Suitable for transporting acidic and alkaline substances, sewage, natural gas, coal gas, and other materials;

5. Good environmental adaptability and frost resistance. Can be used for indoor and outdoor water supply pipelines.

6. Long service life, with a lifespan of over 50 years;

7. Easy to recycle.

Precautions for the Application of Polyethylene Pipeline:

1. For outdoor installation in sunny areas, it is advisable to take shielding measures.

2. For buried HDPE water supply pipelines, when DN≤110, the pipes can be slightly serpentine during summer installation; for DN≥110, due to sufficient soil resistance, it can withstand thermal stress without reserving pipe length; in winter, there is no need to reserve pipe length.

3. When installing HDPE pipes, if the operating space is too small (e.g., pipeline wells, ceiling construction, etc.), electric fusion connection should be used.

4. During heat fusion socket connections, the heating temperature should not be too high or too long; it is best to control the temperature at 210±10°C, otherwise excessive molten material will be extruded from the fittings, reducing the internal diameter for water flow; the socket or pipe joint should be clean; otherwise, it will cause the socket to disconnect and leak; simultaneously, attention should be paid to controlling the angle and direction of the fittings to avoid rework.

5. During hot melt butt connections, the required voltage should be between 200-220V. If the voltage is too high, it will cause the heating plate temperature to be too high; if the voltage is too low, the butt welding machine will not function properly; maintain the alignment of the joints during butt welding; otherwise, it will lead to insufficient butt area, inadequate weld strength, and misalignment; if the joint area is not clean before heating or if the heating plate has oil, dirt, or other impurities, it will cause the joint to disconnect and leak; heating time must be controlled; if the heating time is too short, the pipe will not absorb enough heat, leading to a small weld edge; if the heating time is too long, it will cause too large a weld edge, possibly resulting in a cold weld.

Contact: Manager Zhao

Mobile: 18623755437

Telephone: 0379-60692512

Fax: 0379-65260950

Company Website: www.lygrsjw.com

Factory Address: Zhejiang Business Industrial Park, Matun Town, Mengjin County, Luoyang City, Henan Province

Welcome to visit our factory and order pipelines; we will sincerely provide you with quality product services!