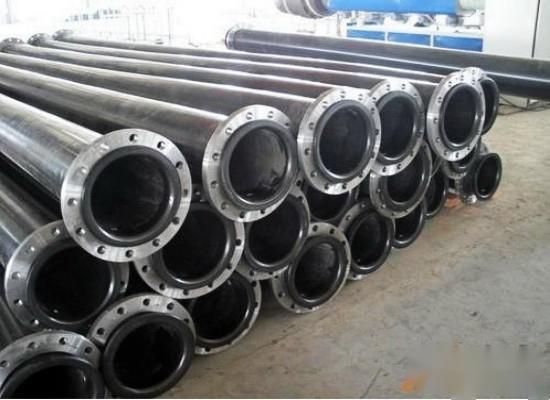

8-inch Sand Suction Pipe (Mobile: 18623755437 Contact: Manager Zhao)

Ultra-high molecular weight polyethylene (UHMW-PE PIPE) refers to linear polyethylene (PE) with a weight-average molecular weight of over 1.5 million (our company's ultra-high molecular weight pipe has an average molecular weight of over 2.5 million). As a new type of engineering plastic pipe with excellent comprehensive performance, ultra-high molecular weight polyethylene wear-resistant pipes have vast market potential for transporting various powders, slurries, fluids, and gases. They can solve the serious wear, corrosion, and scaling problems in the transportation of large quantities and varieties of industrial materials.

8-inch Sand Suction Pipe Product Features:

1, Lightweight Sand Suction Pipe weighs only one-eighth of steel pipes; connected through movable flange bolts, making installation, disassembly, and transportation convenient, reducing start-up time and improving efficiency. After external damage, repairing and replacing the pipe saves costs.

2, Good Toughness of Sand Suction Pipe has high tensile strength and elasticity; the pipe wall does not crack under internal and external force impacts; plastic pipes can connect directly in water, with 4-8 pipes able to bend 360 degrees, providing good resistance to wind and waves; on land, connections can be made directly in areas with undulating surfaces within 30 degrees, without the need to repair the ground.

3, Strong Wear Resistance of Sand Suction Pipe is 4-8 times that of steel pipes, with a longer service life; the pipe material has strong corrosion resistance, remaining unchanged after being submerged in seawater for 50 years; resistant to ultraviolet light and aging, usable for 5-8 years depending on the sand content.

4, Convenient Installation of Sand Suction Pipe both ends of the sand suction pipe have movable metal flanges; the entire finished pipe has no welds, and the pipes are connected directly with bolts through movable flanges; the pipe mouth is lined with a steel ring, ensuring that the pipe mouth does not deform, crack, or leak during long-term installation and disassembly, ensuring high efficiency in transportation projects.

5, Low Friction Coefficient of Sand Suction Pipe, Strong Weather Resistance with smooth inner and outer walls, the ultra-high sand suction pipe has an extremely low friction coefficient, delivering 20%-30% higher transportation efficiency than steel pipes, and can withstand temperatures from -40℃ to 60℃, adaptable to harsh weather temperature changes.

6, Low Cost of Sand Suction Pipe has low total project cost whether used on land or underwater for a long time, providing high efficiency, safety, and convenience.

7, Good Self-Lubrication of Sand Suction Pipe this product contains wax-like substances and has excellent self-lubrication. The friction coefficient (at 196N, 2 hours) is only 0.219MN/m (GB3960). Its sliding performance is better than that of oil-lubricated steel or brass. Especially in harsh environments with dust and silt, the product's dry lubrication performance is more fully demonstrated, allowing for smooth movement and protecting related components from wear or scratches.

8, Extremely High Impact Resistance among existing engineering plastics, this product has a high impact toughness value. Many materials crack, break, or experience surface stress fatigue under severe or repeated explosive impacts. This product meets the GB1843 standard, passing the cantilever beam impact test with no damage.

8-inch Sand Suction Pipe Main Application Areas:

Mining Industry: Slurry transportation pipelines, high-pressure water supply and gas supply pipelines in coal mines.

Power System: Fly ash discharge in thermal power plants, chemical water circulation systems, desulfurization systems.

Coal Industry: Transportation of coal powder and coal-water slurry, ventilation, drainage systems, and desulfurization systems in mines.

Chemical Industry: Transportation of highly corrosive media such as strong acids and strong bases, as well as brine, salt slurry, and raw salt in salt chemical processes.

Oil Extraction: Crude oil transportation, natural gas collection and transportation, sewage reinjection.

Metallurgical Industry: Transportation of coke powder, ore powder, pulp, and smelting oil waste.

Dredging Projects: Transportation of silt in dredging projects for rivers, lakes, ports, and docks.

Marine Engineering: Transportation of seawater and fresh water in seawater desalination.

Municipal Engineering: Sewage treatment, potable water supply, and transportation of gas and natural gas.

8-inch Sand Suction Pipe Engineering Cases:

1· Nanning Sand and Gravel Company in Guangxi: 10 inch sand suction pipe, 500 meters.

2· Luang Prabang Hunan Sand and Gravel Co., Ltd.: 12 inch sand suction pipe, 1000 meters.

3· Zhoushan Wanrong Shipping Company: 20 inch sand suction pipe, 500 meters.

4· Exported to Singapore: 8 inch sand suction pipe, 2000 meters.

5· Hong Kong Chuangyi Shipping Company: sand suction pipe ( 1000m 12 inch sand suction pipe Φ700*1200mm floating body).

6· Tianjin Junlian Marine Engineering Technology Co., Ltd.: 1000 meters 6 inch sand suction pipe and Φ500*800mm floating body).

7· Tianjin Hongda Dredging Co., Ltd.: 2300 meters 12 inch sand suction pipe and Φ1100*1100mm floating body).

8· GAMLA (Nigeria) Limited (produced in South Africa): 1500 meters 8 inch sand suction pipe and floating body Φ500*800mm.