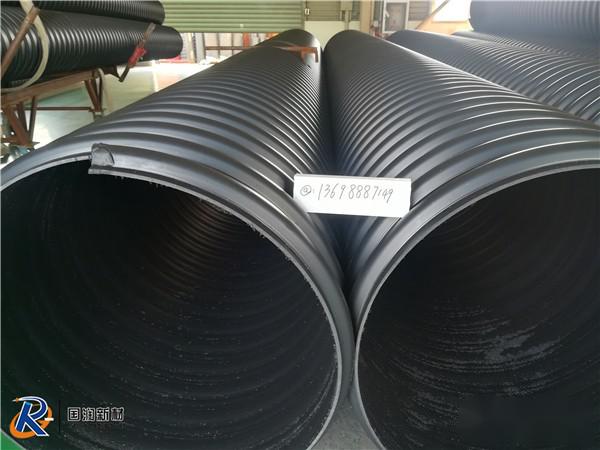

The wall structure of the steel belt corrugated pipe consists of three layers: the inner layer is a continuous solid wall PE inner pipe, which is wound with a (formed from steel plates into a “U” shape) annular corrugated steel belt reinforcement on the outer side of the inner pipe, and an outer layer of polyethylene is compounded on the outside of the corrugated steel belt reinforcement, thus forming an integrated spiral corrugated pipe.

Our steel belt corrugated pipe is a new type of material, similar in appearance to double-wall corrugated pipes, but unlike corrugated pipes and double-wall corrugated pipes, it uses a special process to compound a layer of steel belt at the peaks of the internal structure, enhancing ring stiffness, compressive strength, and impact resistance, making it suitable for various engineering needs. The price for DN400 “U” shaped steel belt corrugated pipe is around 115 yuan per meter, depending on the order quantity, with discounts for bulk orders, direct sales from the manufacturer. If interested, please feel free to contact me (136-9888-7149).

Precautions for transporting and storing steel belt PE corrugated pipes:

1) During loading and unloading transportation, the pipes should not be subjected to severe impacts, drops, or heavy pressure.

2) When using machinery to load and unload the pipes, the two lifting points on the pipe should be about 1/4 of the pipe length from both ends.

3) The bottom of the vehicle or ship that comes into contact with the pipes should be as flat as possible, and measures should be taken to prevent rolling and mutual collisions. They should not come into contact with sharp objects to avoid scratching the pipes.

Storage: The pipes should be stored away from heat sources and chemical contaminants, in a warehouse with a flat ground surface and good ventilation. If stored outdoors, there should be coverings. The pipes should be stacked horizontally and neatly.

If you ask which manufacturer produces the best PE steel belt reinforced corrugated pipes, it is still Luoyang Guorun Pipe Industry. The PE steel belt reinforced corrugated pipes produced by Guorun Pipe Industry receive high praise from customers, looking vibrant in color and feeling very textured, with favorable prices. Interested customers are welcome to visit the factory.

Advantages of steel belt PE corrugated pipes:

1. Chemical resistance: not polluted, resistant to wastewater and chemical corrosion, not corroded by decomposing substances in the soil;

2. Impact resistance: The pipe wall uses a 'U' shaped structure, resistant to impact and pressure, does not crack under foundation settlement, and has strong recovery after deformation, with good adaptability to foundations;

3. Aging resistance: The pipes are usually black, capable of withstanding direct sunlight during storage and construction;

4. Cold resistance: The pipes will not freeze or expand and leak in an environment of -60℃;

5. Lightweight: Easy to transport and convenient for construction, weighing only 1/8 of cement pipes, requiring only an excavator for burial, no large equipment needed;

6. Convenient connection: The pipes can be connected outside the trench and then pushed into the trench with an excavator, reducing construction time and costs;

7. Superior wear resistance: More wear-resistant than steel pipes and cement pipes, with strong capacity for transporting wastewater and waste;

8. Excellent drainage flow: The internal surface is smooth, reducing friction and allowing for fast drainage;

9. Economy: Low construction, management, and maintenance costs;

10. Environmental impact: HDPE is a non-toxic material, harmless to land and other environments, and can be recycled.

Luoyang Guorun New Material is a high-tech enterprise integrating R&D, production, and sales services, covering an area of over 200 acres with more than 200 employees. The company is dedicated to the R&D, production, and promotion of new wear-resistant and anti-corrosion pipes. Main products include ultra-high molecular weight polyethylene pipes, ultra-high composite pipes, HDPE pipes, steel belt reinforced polyethylene (HDPE) spiral corrugated pipes, anti-corrosion chemical water pipelines, steel-lined fluorine plastic pipelines, dredging pipelines, and dual-wall corrugated pipe manufacturers for sand suction and drainage rubber hoses, as well as various series and specifications of pipes and matching fittings.

Luoyang Guorun New Material -- Welcome new and old customers to visit our company!

Sales Manager: Manager Sun 136 9888 7149, 0379-6522 7507

Factory Address: China. Luoyang Airport Industrial Cluster Area, Zhejiang Business Industrial Park