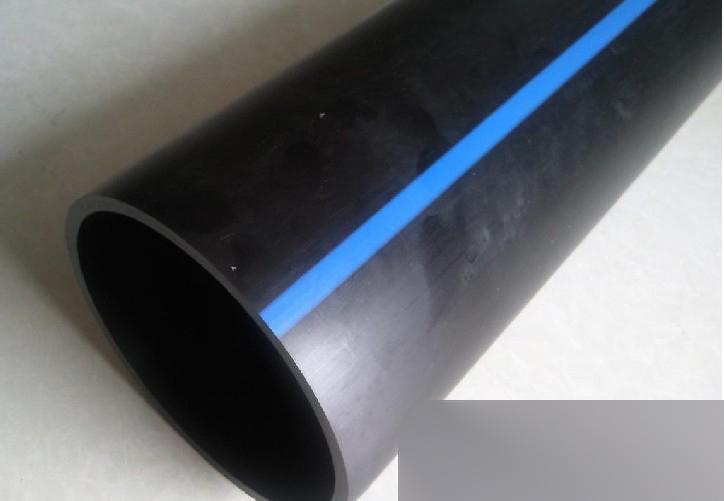

HDPE Water Supply Pipe, 200PE Water Supply Pipe

In the HDPE water supply pipe system, plastic pipes have gradually replaced traditional materials such as cast iron and galvanized steel pipes, becoming the mainstream choice. Compared with traditional pipes, PE pipes have significant advantages such as light weight, corrosion resistance, low water flow resistance, energy savings, ease and speed of installation, and lower cost, making them favored in the pipeline engineering field. At the same time, with the rapid development of the petrochemical industry and continuous advancements in plastic manufacturing technology, the production of plastic pipes has swiftly increased, and the variety of products has become more diverse.

HDPE water supply pipes have become the second most consumed type of plastic piping after PVC-U water supply pipes. For gas transportation, PE80 and PE100 grades of medium or high-density polyethylene pipes should be used; PE pipes typically use PE80 and PE100 grades, while PE63 is gradually being phased out. In terms of water transport, the growth of PE100 pipe systems is rapid, with an expected growth rate of over 10% in the next five years.

HDPE Water Supply Pipe, HDPE Drainage Pipe, HDPE Pipe, φ200PE Water Supply Pipe

HDPE drainage pipes must withstand certain pressures and typically require the selection of high molecular weight, mechanically strong PE resins, such as HDPE resins. LDPE resins have low tensile strength, poor pressure resistance, low rigidity, and poor dimensional stability during processing, making them unsuitable as materials for water supply pressure pipes due to difficult connections. However, due to their high hygiene standards, LDPE, especially LLDPE resins, have become commonly used materials for producing drinking water pipes. LDPE and LLDPE resins have low melt viscosity, good fluidity, and are easy to process, resulting in a broader selection range for their melt index, usually between MI of 0.3-3g/10min.

HDPE Drainage Pipe, HDPE Water Supply Pipe, PE Pipe Advantages, φ200PE Water Supply Pipe

HDPE water supply pipelines are widely used mainly due to their unmatched advantages over other pipelines:

1. HDPE water supply pipes are easy to socket weld and electro-fuse, forming a complete closed seepage-proof system. When laid along trenches, they can reduce the volume of excavated soil and decrease the amount of fittings required. HDPE water supply pipes

2. PE water supply pipes are lightweight and easy to install;

3. HDPE water supply pipes have strong wear resistance and excellent hydraulic properties, allowing them to be buried without external protection. They are suitable for earthquake-prone areas and subsidence zones in mining areas, and can also be laid using the sinking method at the bottom of rivers. HDPE water supply pipes

4. PE pipes are resistant to chemical corrosion, internal and external corrosion, and microbial corrosion, having strong corrosion resistance and health safety. They are suitable for transporting acidic and alkaline substances, sewage, natural gas, and coal gas; HDPE water supply pipes

5. 200PE water supply pipes have good environmental adaptability and frost resistance. They can be used for both indoor and outdoor water supply pipelines.

6. HDPE drainage pipes have a long service life, exceeding almost 50 years;

7. PE water supply pipes are easy to recycle.

Contact Person: Manager Zhao

Mobile:18623755437

Telephone: 0379-60692512

Fax: 0379-65260950

Company Website: www.lygrsjw.com

Email: 874689613@qq.com

Factory Address: Zhejiang Merchant Industrial Park, Matun Town, Mengjin County, Luoyang City, Henan Province

Welcome to purchase our polyethylene pipes, we will provide you with quality product services!