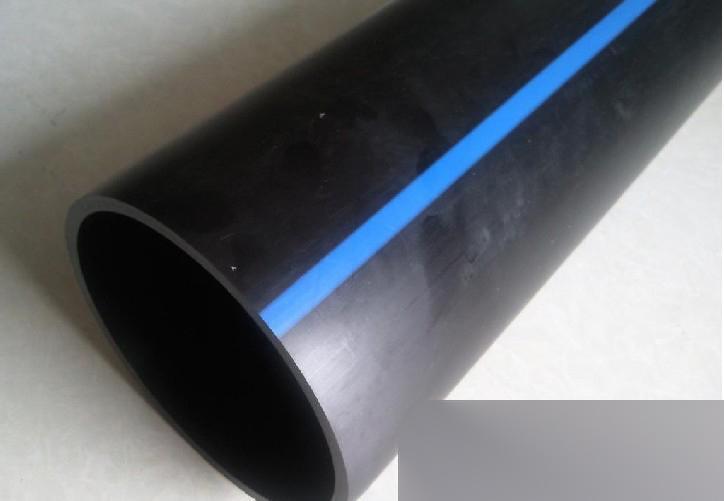

160PEPipe

HDPE drainage pipes are thermoplastic plastic circular pipes primarily made from high-density polyethylene resin, produced using an extrusion molding process for applications without internal pressure. HDPE drainage pipes are a replacement for traditional steel pipes and PVC drainage pipes, mainly tasked with draining rainwater, sewage, and agricultural irrigation. They are widely used in drainage fields such as highway and railway subgrades, subway projects, waste landfills, tunnels, green belts, sports fields, and slope protection due to high moisture content, as well as in underground irrigation and drainage systems in agriculture and horticulture.

160PEPipe, Drainage Safety:

The outlet is located in the trough, and due to the bidirectional action of the peaks and filter fabric, the outlet is not easily clogged, ensuring smooth operation of the drainage system.

160PEPipe, Corrosion Resistance:

In comparison with flexible spring drainage pipes, plastic is less susceptible to rust.

Strength and Easy Bending Integration:

The unique double-walled structure effectively enhances the product's external pressure strength, ensuring that the drainage system does not deform under external pressure, thus maintaining drainage effectiveness.

160PEPipe, Economical:

Compared to other drainage pipes of the same diameter, its price is relatively lower.

160PEPipe, Product Applications:

1. Longitudinal and transverse drainage and infiltration for highways;

2. Vertical and horizontal drainage behind various earth retaining walls and ditches on highways;

3. Drainage for tunnels and underpasses;

4. Water supply and drainage for municipal engineering, water treatment plants, sewage treatment plants, landfills, etc.;

5. Drainage for recreational green spaces such as golf courses, sports fields, and parks;

6. Slope soil and water conservation in hillside development;

7. Underground drainage for land leveling projects;

160PEPipe, Main Technical Indicators:

1. Vertically pressurized to 40% of the outer diameter, immediately unloading, the sample does not rupture or delaminate.

2. At a temperature of 0℃ and a height of 1M, using a weight of 1Kg, impact 10 times, with no cracking occurring more than 9 times.

3. The inner wall is uniformly smooth, and the drainage holes are evenly punched below 1/2 of the trough height, with the number of holes above 1/2 of the trough height not exceeding 10% of the total.

4. Permeable area ≥45cm2/M.

5. Longitudinal shrinkage rate ≤3.0%.

6. Bending degree %≤2.

7. Ring stiffness ≥6.3KN/m2.

Contact Person: Manager Zhao

Mobile: 18623755437

Telephone: 0379-60692512

Fax: 0379-65260950

Company Website: www.lygrsjw.com

Factory Address: Zhejiang Business Industrial Park, Matun Town, Mengjin County, Luoyang City, Henan Province.

Welcome to visit our factory and order pipes; we will sincerely provide you with product services!