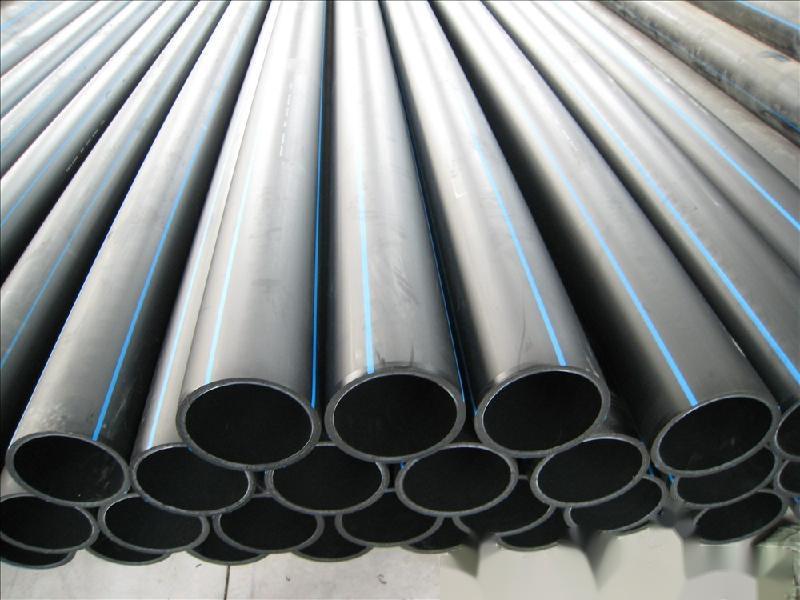

110PEDrainage Pipe

PE (Polyethylene) material is widely used in the manufacturing of water supply pipes due to its high strength, high-temperature resistance, corrosion resistance, and non-toxicity. It is an ideal piping material to replace ordinary iron water supply pipes because it does not rust. The 110PE drainage pipe complies with the national product standard: GB/T 13663-2000 "Polyethylene (PE) Pipes for Water Supply."

The development of plastic pipes in China is rapid, and the quality is continuously improving. Among them, polyethylene (PE) pipes are widely used in building water supply, building drainage, underground drainage pipes, building heating, gas transmission pipes, electrical and telecommunications protective conduits, industrial pipes, and agricultural pipes due to their unique advantages. They are primarily applied in urban water supply, urban gas supply, and farmland irrigation.

Today, the connection technology of polyethylene has become very mature and reliable. Statistics show that the leakage rate of polyethylene pipes is less than 0.0002, far lower than the 2-3% of ductile iron pipes, significantly improving the safety and economic benefits of the pipes. This is also a very important reason for the extensive use of polyethylene pipes in gas pipelines.

(1)Polyethylene has excellent corrosion resistance, good hygiene performance, and a long service life

The 110PE drainage pipe is made of inert materials and can resist corrosion from various chemicals, except for a small number of strong oxidizers, and is not prone to bacterial growth. It is well known that steel and cast iron pipes are replaced by plastic pipes not only because plastic pipes have lower water transport energy consumption, lower living energy consumption, are lightweight, have lower water flow resistance, are easy to install quickly, are cost-effective, have a long service life, and provide insulation, but also because plastic pipes have superior corrosion resistance and are less prone to microbial growth compared to steel and cast iron pipes.

(2)Polyethylene has uniqueflexibility and excellent scratch resistance

The unique flexibility of the 110PE drainage pipe allows it to effectively resist underground movements and end loads. In terms of strength and rigidity, plastic underground pipes are not as strong as cement or metal pipes, but in practical applications, plastic underground pipes are considered "flexible pipes" and, under proper design and construction, the plastic underground pipes share the load with the surrounding soil. Therefore, plastic underground pipes do not need to achieve the same strength and rigidity as "rigid pipes" to meet the mechanical performance requirements for underground use.

(3)Polyethylene has outstanding low-temperature resistance

The low-temperature embrittlement point of the 110PE drainage pipe is -70℃, which is better than other pipes. During winter outdoor construction, polyvinyl chloride (PVC-U) pipes are prone to brittle cracking. An experience summarized from pilot projects laying PVC-U underground water supply pipes in Beijing, China, is that temperatures below zero degrees Celsius are not suitable for PVC-U pipe installation. Another clear evidence is that to improve the toughness and low-temperature impact resistance of PP, ethylene can be copolymerized with propylene monomers to produce random copolymer polypropylene (PP-R), which generally employs the IPP process route and method, allowing the mixed gases of propylene and ethylene to copolymerize, resulting in a copolymer with propylene and ethylene segments distributed irregularly along the main chain (i.e., PP-R pipe material). The ethylene content in PP-R pipe materials is mostly around 3%. However, the improved low-temperature resistance of PP-R is still not satisfactory, with an embrittlement point of about -15℃, which is much higher than the embrittlement point of polyethylene pipes at -70℃.

The standard specifies the product specifications, technical requirements, testing methods, inspection rules, marking, packaging, transportation, and storage for polyethylene pipes (hereinafter referred to as "pipes") made from polyethylene resin as the main raw material through extrusion molding. This standard also specifies the basic performance requirements of the raw materials, including the classification system.

This standard applies to water supply pipes made from PE63, PE80, and PE100 materials. The nominal pressure of the pipes is 0.32MPa to 1.6MPa, and the nominal outer diameter ranges from 16 mm to 1000 mm.

The pipes specified in this standard are suitable for pressure water transmission for general purposes at temperatures not exceeding 40°C, as well as for the transportation of drinking water.

Contact Person: Manager Zhao

Mobile: 18623755437

Phone: 0379-60692512

Fax: 0379-65260950

Company Website: www.lygrsjw.com

Factory Address: Zhejiang Merchants Industrial Park, Matun Town, Mengjin County, Luoyang City, Henan Province

Welcome to visit our factory and order pipes. We will sincerely provide you with product services!