Zhejiang University Li Zhenglong's team: Photocatalytic oxidative depolymerization of polyethylene waste plastics into aliphatic long-chain dicarboxylic acids.

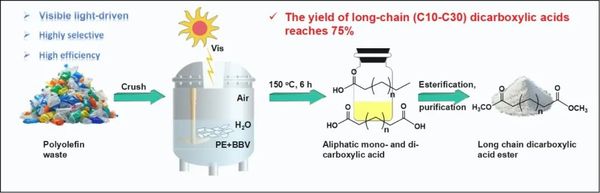

Recently, the global annual production of polyethylene (PE) has reached 83 million tons, making it one of the most widely used plastics. The long-term accumulation of PE waste poses a serious threat to the environment. This study demonstrates a method for the photocatalytic oxidation of polyethylene (PE) to generate higher-value aliphatic diacids (C4-C30) using a BiOI/BiVO4 p-n heterojunction material under visible light irradiation. This method achieves a high carbon yield of up to 83% under mild conditions, and by optimizing the composition of the heterojunction and reaction conditions, the yield of long-chain diacids (C10-C30) can be increased to 75%. The authors also explored the effects of reaction temperature, time, air pressure, and the stability of the catalyst after multiple cycles on the photocatalytic oxidation of PE. Various techniques were employed to elucidate the reaction mechanism: superoxide radicals (•O2-) are responsible for activating the C-H bonds in the PE main chain, while hydroxyl radicals (•OH) cleave the C=C bonds. Furthermore, the photocatalytic upgrading process has shown significant efficiency for various commercial PEs used in daily life. This photocatalytic system offers a promising approach for the efficient recycling of PE waste.

Figure 1. Schematic diagram of the photocatalytic oxidation depolymerization of polyethylene waste plastics to binary carboxylic acids proposed in this article.

Background introduction:

With the continuous increase in plastic waste, the efficient recycling of plastics has become a pressing environmental issue. Particularly for plastics like polyethylene (PE), their stability and durability result in extremely slow degradation rates in the environment, posing long-term threats to ecosystems. Currently, chemical recycling methods for plastics, especially polyethylene, face limitations such as high energy consumption and secondary pollution. To address these challenges, scientists are exploring more environmentally friendly and low-energy plastic recycling methods. Photocatalytic systems have emerged as an attractive option due to their use of renewable solar energy and relatively mild operating conditions. In recent years, photocatalytic systems have made progress in the degradation and recycling of plastic waste. Researchers aim to mimic natural degradation mechanisms through reactive species like free radicals, enabling the green recycling of polyolefin waste. The BiOI/BiVO4 p-n heterojunction material has been proposed as a photocatalyst due to its stability and non-toxicity. In this study, researchers developed this material and successfully achieved the photocatalytic oxidation of polyethylene under mild conditions using visible light irradiation. Against the backdrop of the search for eco-friendly, low-energy plastic recycling technologies, this study leverages the photocatalytic properties of the BiOI/BiVO4 p-n heterojunction material to efficiently convert polyethylene waste into higher-value chemicals.

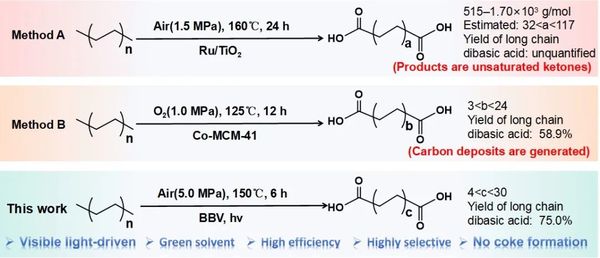

Figure 2. Comparison of this catalytic system with existing methods.

Highlights of this article:

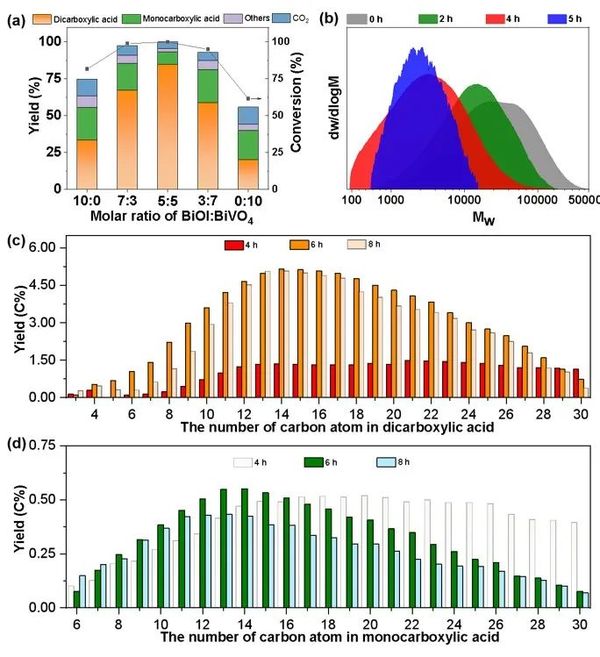

This work successfully achieved the photocatalytic oxidation of polyethylene (PE) to valuable aliphatic dicarboxylic acids (C4-C30) under mild conditions using a BiOI/BiVO4 p-n heterojunction, with a carbon yield up to 83%. Notably, the carbon yield for long-chain dicarboxylic acids (C10-C30) reached 75%.

Figure 3. (a) Reaction results of PE on different catalysts, (b) Molecular weight of PE, (c) Dicarboxylic acids, (d) Distribution of monocarboxylic acid products over time.

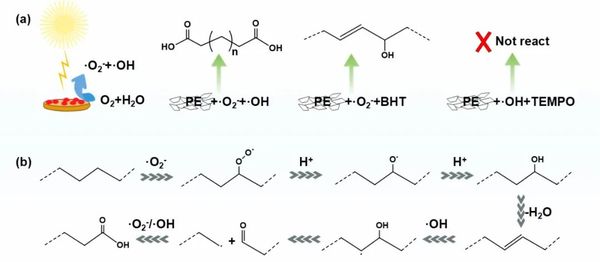

In the photocatalytic oxidation process, superoxide radicals (•O₂⁻) and hydroxyl radicals (•OH) play a crucial role. The superoxide radicals activate the C-H bonds in the PE main chain, while the hydroxyl radicals oxidize and break the C=C bonds, ultimately converting PE into dicarboxylic acid products.

Figure 4. Proposed reaction mechanism

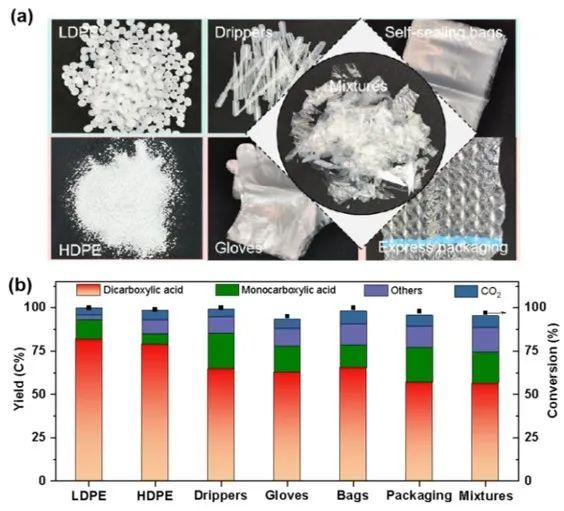

The catalytic system can oxidatively depolymerize most commercial polyethylene (PE) into dicarboxylic acids, with a carbon yield ranging from 59% to 64%. Trace amounts of branched alkanes and cycloalkanes were detected in the products. This photocatalytic system demonstrates excellent stability when processing commercial PE waste, indicating its potential for practical applications.

Figure 5. Results of photocatalytic oxidative depolymerization of pure PE particles and commonly found PE waste plastics in daily life.

Summary and Outlook:

Developing green chemical methods for the efficient recycling of waste polyolefins is crucial for reducing carbon emissions and supporting sustainable development. By converting PE into valuable chemicals (long-chain dicarboxylic acids), it is possible to add value to plastic waste, providing feedstock for the production of biodegradable polymers, lubricants, surfactants, and more. The photocatalytic oxidation method proposed in this study can be performed under mild conditions, significantly reducing the energy and resource inputs required by conventional methods, and is expected to advance the development of polyolefin waste plastic recycling technologies.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track